Converse construction process for middle-high steel structure building

A technology of construction technology and steel structure, which is applied in the direction of construction, building structure, and building material processing. It can solve the problems of inability to meet the overall installation quality standard, less construction work surface, and long-term steel components, so as to prevent welding deformation. , convenient construction and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

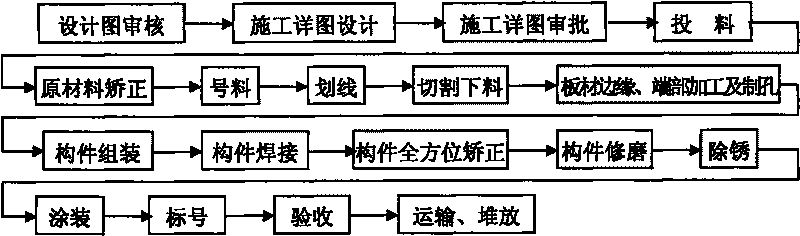

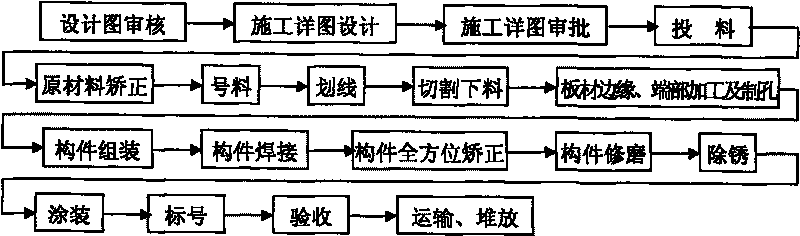

[0007] The reverse construction technology of medium and high-rise steel structure buildings includes the following steps:

[0008] 1. Refine and expand the joint design of the connection joints of the steel structure frame

[0009] 1. Using AUTOCAD2004 drawing software, carry out 1:1 drawing lofting of the steel structure frame joint structure according to the design size according to the horizontal, vertical and section, and conduct detailed research on the joints of various joints. Expand the design of the original design plane and elevation with the axis as the unit, and number the components;

[0010] 2. Use the steel structure connection node calculation software to calculate the connection force of various components, use CAD drawing software as the graphic design platform, enlarge the sample of complex connection nodes and complex components, establish a steel structure node library, and realize the computerization of graphic information;

[0011] 3. There are many ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com