Corneal contact lens preserving liquid composition and preparation method thereof

A technology of corneal contact lens and composition, which is applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of poor wettability of the lens, and achieve the effect of alleviating dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

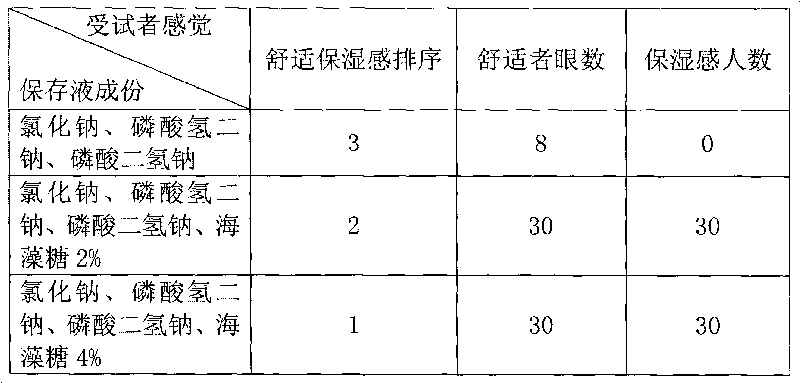

Examples

Embodiment 1

[0018] Trehalose 1%, lubricating and moisturizing agent: polyvinylpyrrolidone 0.003%, isotonicity regulator: sodium chloride 0.5%, buffering agent: boric acid 0.64%, borax 0.09%, pure water 97.76%.

Embodiment 2

[0020] Trehalose 2%, lubricating and moisturizing agent: polyvinyl alcohol 0.006%, isotonicity regulator: sodium chloride 0.83%, buffering agent: disodium hydrogen phosphate 0.17%, sodium dihydrogen phosphate 0.03%, pure water 96.96%.

Embodiment 3

[0022] Trehalose 2%, lubricating and moisturizing agent: poloxamer 0.5%, isotonicity regulator: potassium chloride 0.83%, buffering agent: disodium hydrogen phosphate 0.17%, sodium dihydrogen phosphate 0.03%, pure water 96.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com