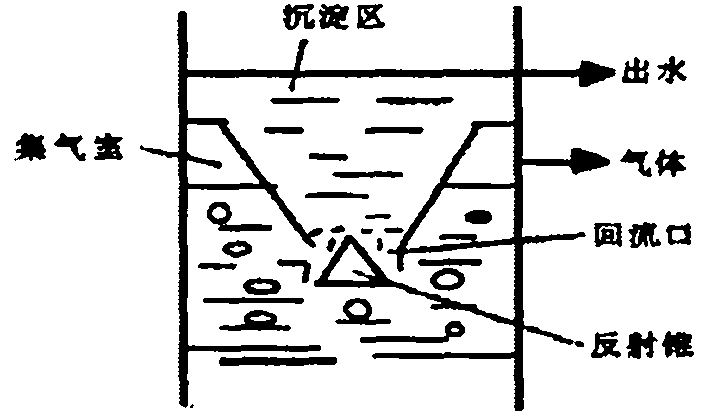

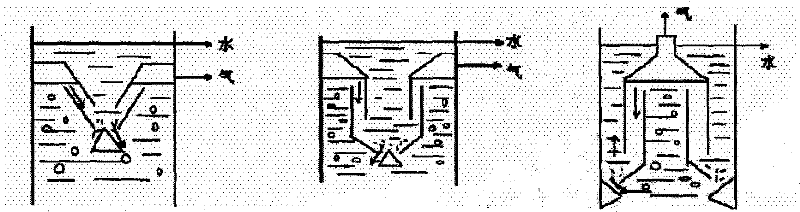

A three-phase separator for an anaerobic reactor

A three-phase separator and anaerobic reactor technology, applied in the field of three-phase separators, can solve the problems of affecting sludge settlement, complex structure, mutual interference, etc., and achieve the effects of easy floating removal, increasing flow area, and reducing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

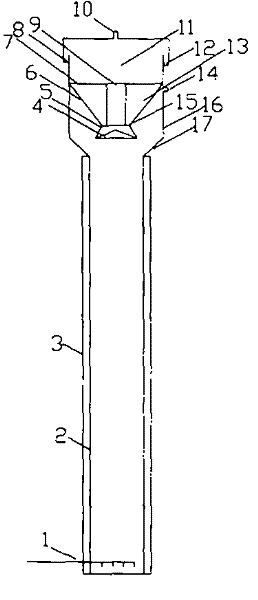

[0023] The structure of the present invention is as described above, wherein the diameter of the reactor shell 2 is 3 meters, the diameter of the three-phase separator outer cylinder 16 is 4 meters, the connecting cone 17 and the horizontal angle are 45 °, the conical guide cylinder 6 and the horizontal The included angle is 60°. The diameter of the reflection cone 4 is 0.6 meters, the diameter of the cylindrical guide tube is 0.3 meters, the ratio of the diameter of the cylindrical guide tube 9 to the bottom diameter of the conical sedimentation zone 6 is 0.7, and the height of the solid-liquid separation zone 11 is 0.6 meters.

Embodiment 2

[0025] The structure of the present invention is as described above, wherein the diameter of the reactor shell 2 is 8 meters, the diameter of the three-phase separator outer cylinder 16 is 10 meters, the connecting cone 17 and the horizontal angle are 45 °, the conical guide cylinder 6 and the horizontal The included angle is 45°. The diameter of the reflection cone 4 is 1.4 meters, the diameter of the cylindrical guide tube is 0.8 meters, the ratio of the diameter of the cylindrical guide tube 9 to the bottom diameter of the conical sedimentation zone 6 is 0.7, and the height of the solid-liquid separation zone 11 is 1 meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com