Tri-phase separator of anaerobic reactor

A three-phase separator and anaerobic reactor technology, applied in anaerobic digestion treatment and other directions, can solve the problems of affecting sludge settlement, complex structure, mutual interference, etc., and achieve easy floating removal, increase flow area, and reduce pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

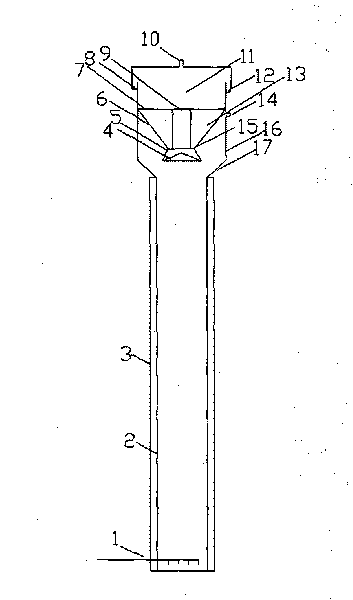

[0022] The structure of the present invention is as described above, wherein the diameter of the reactor shell 2 is 3 meters, the diameter of the three-phase separator outer cylinder 16 is 4 meters, the connecting cone 17 and the horizontal angle are 45 °, the conical guide cylinder 6 and the horizontal The included angle is 60°. The diameter of the reflecting cone 4 is 0.6 meters, the diameter of the cylindrical guide tube is 0.3 meters, the ratio of the diameter of the cylindrical guide tube 9 to the bottom diameter of the conical sedimentation zone 6 is 0.7, and the height of the solid-liquid separation zone 11 is 0.6 meters.

Embodiment 2

[0024] The structure of the present invention is as described above, wherein the diameter of the reactor cylinder 2 is 8 meters, the diameter of the three-phase separator outer cylinder 16 is 10 meters, the connecting cone 17 and the horizontal angle are 45 °, the conical guide cylinder 6 and the horizontal The included angle is 45°. The diameter of the reflection cone 4 is 1.4 meters, the diameter of the cylindrical guide tube is 0.8 meters, the ratio of the diameter of the cylindrical guide tube 9 to the bottom diameter of the conical sedimentation zone 6 is 0.7, and the height of the solid-liquid separation zone 11 is 1 meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com