Oil filter of nonferrous metal foil rolling industry

A non-ferrous metal and oil filter technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of frequent slag discharge of filter cloth and filter soil, environmental pollution, waste of resources, etc., and achieve saving of slag discharge Cloth changing time, labor intensity reduction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

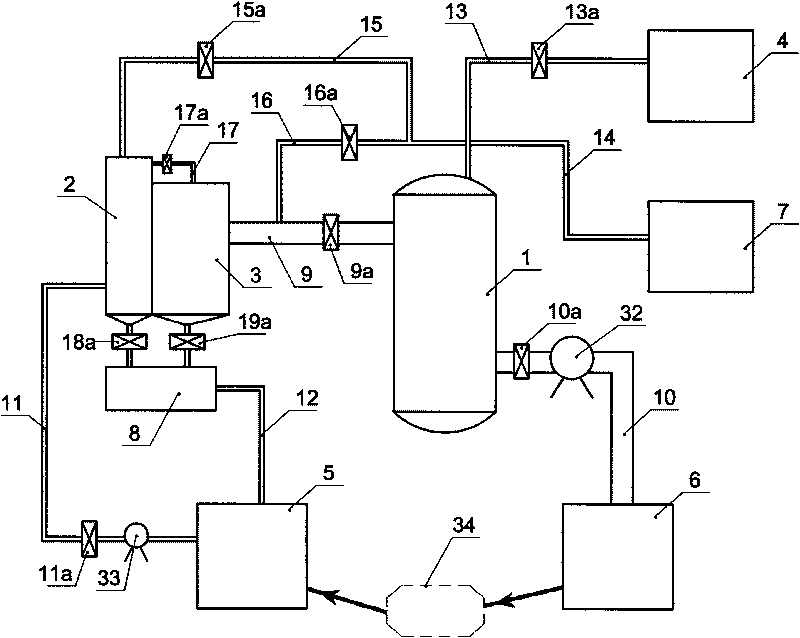

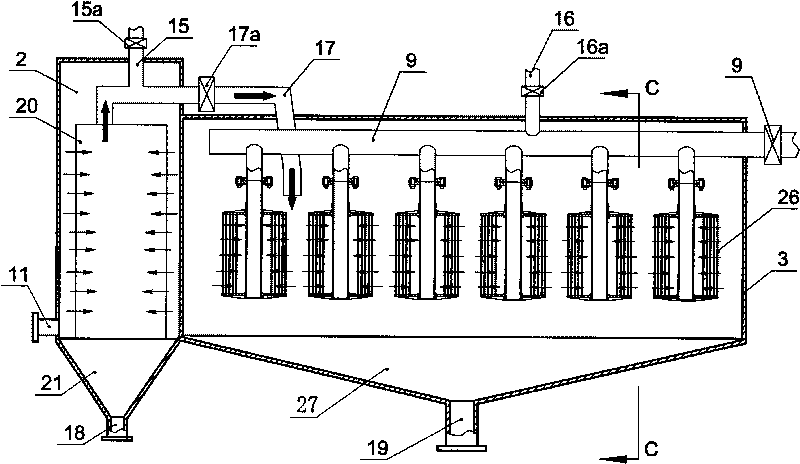

[0031] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 6-1 , an oil filter machine for the non-ferrous metal foil rolling industry, including a dirty oil pool 5, a clean oil pool 6, and an oil filtering system, the oil filtering system includes a coarse oil-water separation device 2, a fine filter decolorization device 3, a buffer tank 1 and communication with it Vacuum pump 4, the filtration process of the oil filtration system is to discharge dirty oil from the rolling mill → dirty oil pool 5 → coarse filter oil-water separation device 2 → fine filter decolorization device 3 → buffer tank 1 → oil well pump 32 → clean oil pool 6 → rolling mill. Wherein the buffer tank 1 is communicated with the vacuum pump 4 to ensure that the buffer tank 1 is in a negative pressure state during operation.

[0032] A dehydration mechanism is installed in the coarse filter oil-water separation device 2, and the dehydrated dirty oil is intr...

Embodiment 2

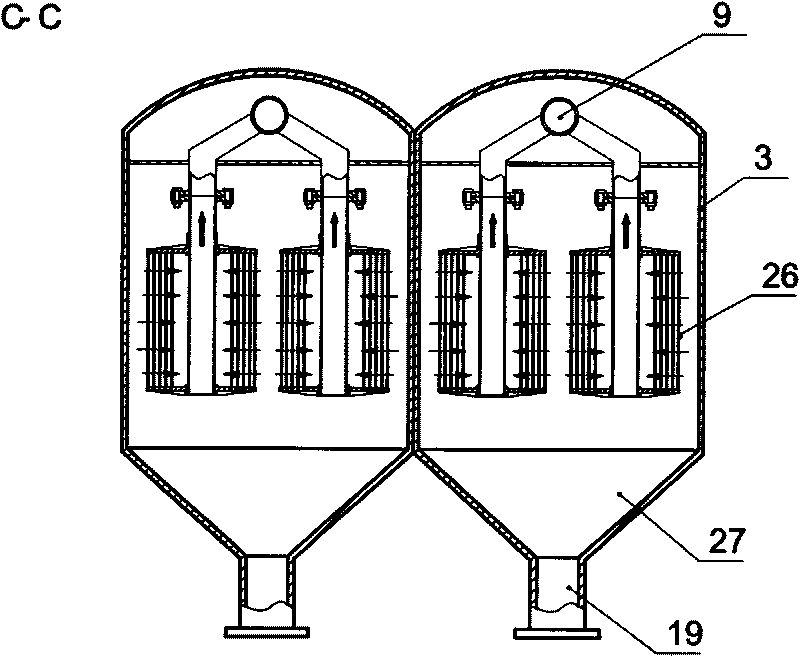

[0041] Embodiment two: see figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 6-1 , Figure 7 , Figure 8 , the numbering is the same as in Embodiment 1, the meaning is the same, and the same parts will not be repeated. The difference is that multiple rows of decolorizing and impurity-removing filter cores 26 are installed in the cavity of the fine filter and decolorization device 3, and the cavity of the fine filter and decolorization device is covered by a horizontal The support plate 37 is divided into upper and lower two fully enclosed cavities, which are respectively a negative pressure chamber 35 and an oil chamber 36, and a solenoid valve for discharging residual pressure is arranged on the negative pressure chamber. The suction tubes 30 at the upper ends of the decolorizing and impurity-removing filter elements 26 are respectively fixed on the support plate 37 , and the suction tubes 30 communicate with the negative pressure chamber 35 . The net oil extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com