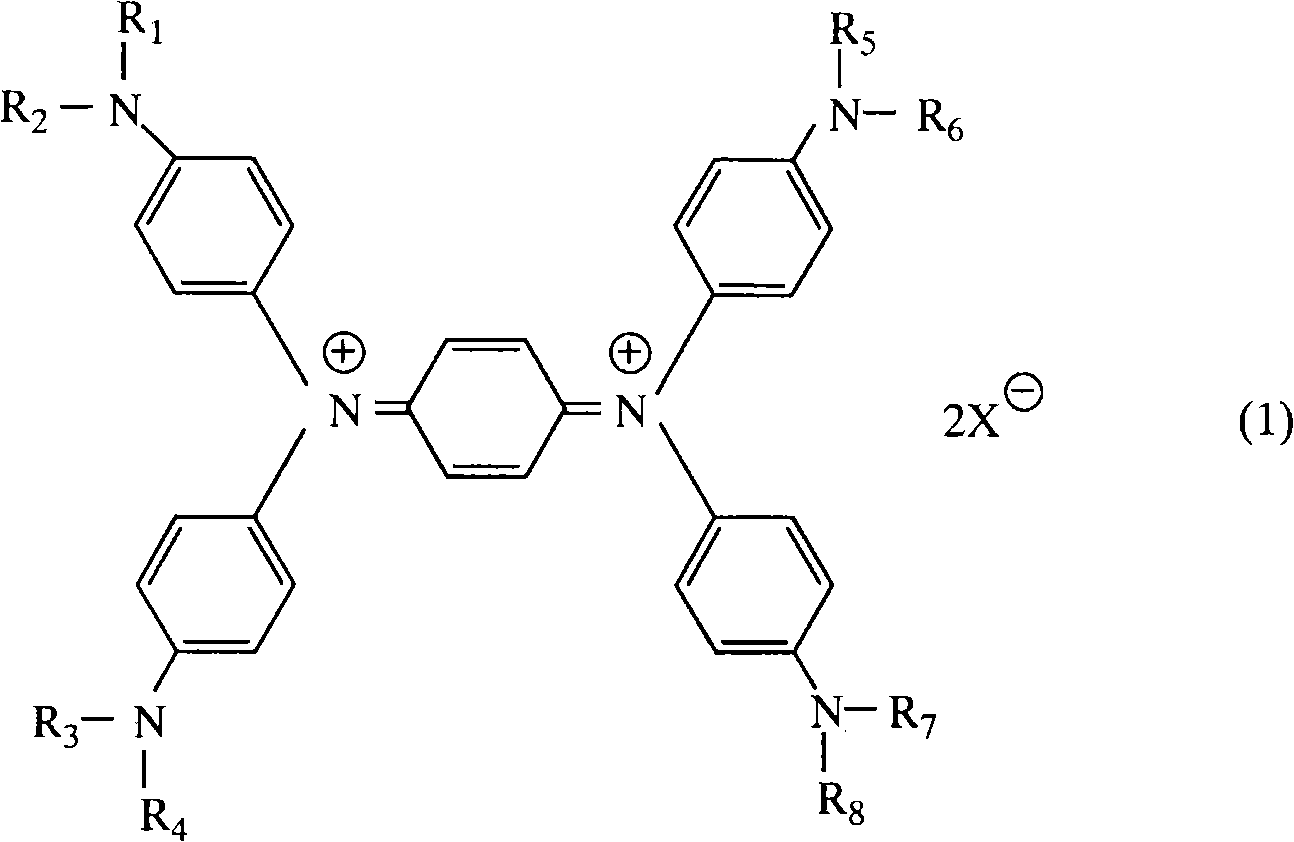

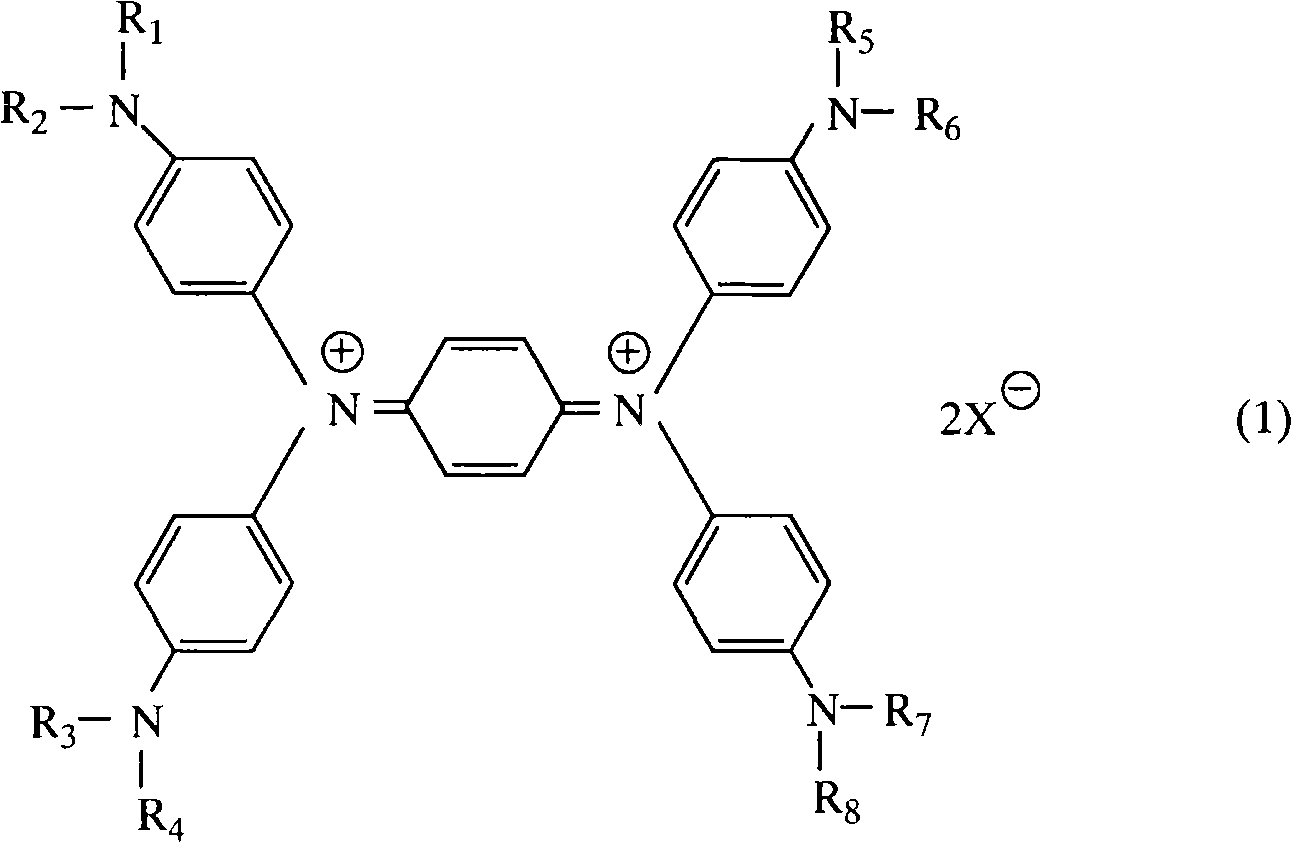

Near-infrared-absorbing film and optical filter employing the same for plasma display panel

A near-infrared and absorbing film technology, which is applied in the field of optical films, can solve the problem of difficult formation of adhesive layer processing and adhesive layer, and achieve the effects of easy manufacture, excellent heat resistance or stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

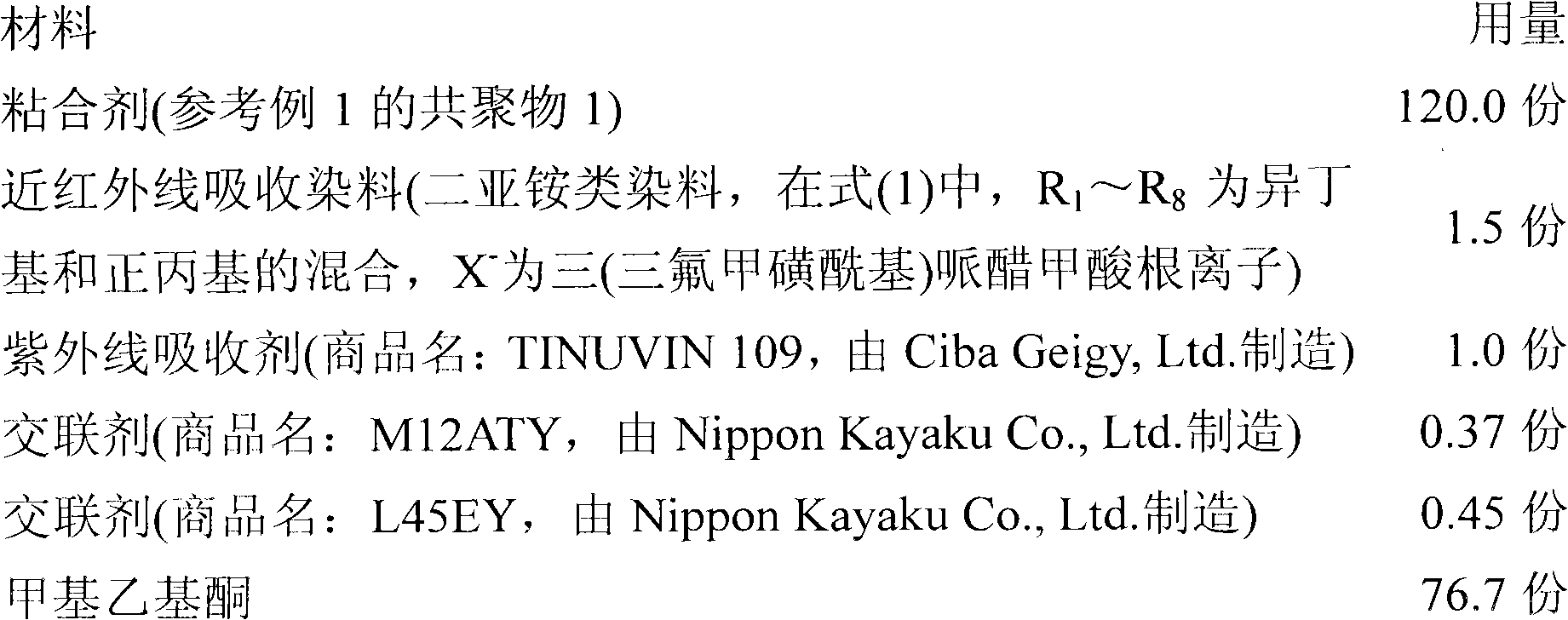

[0073] The present invention will be described in more detail below by way of examples, but the present invention is not intended to be limited to these examples. In the examples, unless otherwise specified, the term "part" means part by weight, and the term "%" means percentage by weight.

reference example 1

[0074] Reference example 1 (synthesis of copolymer 1)

[0075] Add 64 parts of butyl acrylate, 32 parts of cyclohexyl acrylate and 4 parts of acrylic acid and 100 parts of ethyl acetate as monomers and 100 parts of ethyl acetate as the working solvent into a 1 L volume equipped with stirrer, condenser tube, temperature sensor and nitrogen inlet tube flask, and stir the mixture to dissolve. Nitrogen gas was introduced to adjust the oxygen concentration in the gas phase to 0.1% by volume or less, and then the solution was heated to 70°C. 0.020 parts of azobisisobutyronitrile as a polymerization initiator dissolved in a small amount of ethyl acetate was added to the flask, and the obtained mixture was polymerized under heating for 7 hours while the temperature was kept at 70°C. Thus, a copolymer 1 of butyl acrylate, cyclohexyl acrylate and acrylic acid was obtained. Methyl ethyl ketone was added to the copolymer, and the copolymer was dissolved to a copolymer concentration of 2...

reference example 2

[0076] Reference example 2 (synthesis of copolymer 2)

[0077] Copolymer 2 of butyl acrylate, isobornyl acrylate and acrylic acid was obtained in a similar manner to that used in Reference Example 1, except that 72 parts of butyl acrylate, 24 parts of isobornyl acrylate and 4 parts of acrylic acid were used as a monomer. Methyl ethyl ketone was added to the copolymer, and the copolymer was dissolved to a copolymer concentration of 25%, whereby a resin solution was obtained. The weight average molecular weight measured by GPC was 1,100,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com