Method for improving sheet quality by increasing retention of filler calcium carbonate in sheet

A technology of calcium carbonate and retention rate, applied in the directions of tobacco preparation, application, tobacco, etc., can solve problems such as low research level of tobacco processing technology, and achieve the effects of significant technical effect, quality improvement, and retention rate improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

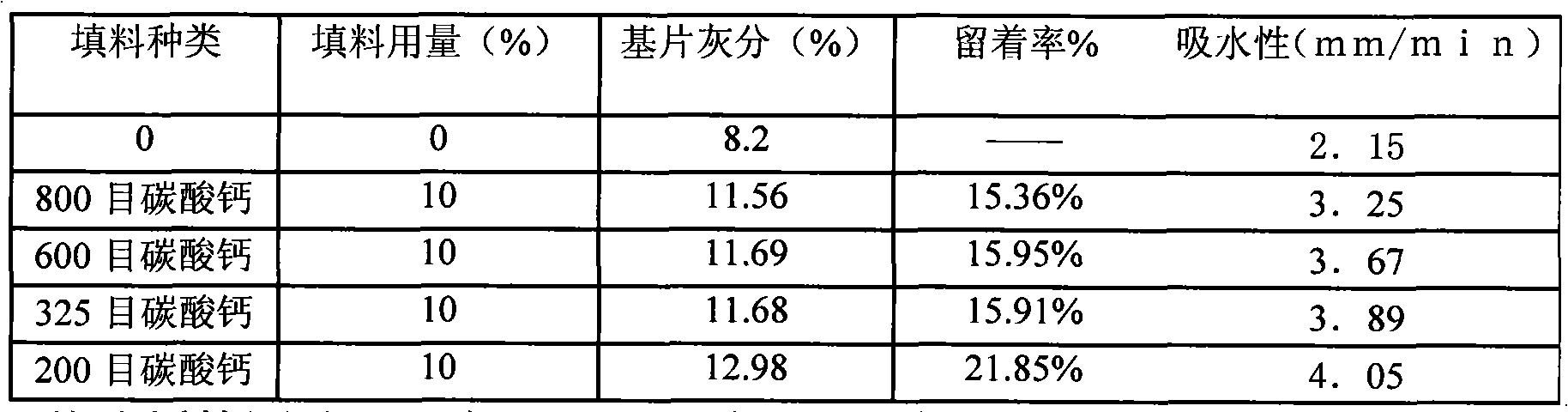

[0040] Select 200 mesh flake-shaped calcium carbonate, join in the mixed slurry of tobacco flakes by 7.5% of raw material consumption, after stirring for 30 minutes under the strong electromagnetic stirrer; Dilute the anion trapping agent 10 times and press 0.2% consumption respectively Add to the slurry and stir evenly, then dilute the guar gum to 0.1% concentration, add 0.08% into the slurry and stir evenly; according to 65±3g / m 2 Quantitatively copy the film and test its ash value, filler retention rate, and water absorption performance. Compared with the original process of 800 mesh.

[0041] Table 4 Comparison of 200 mesh calcium carbonate with the current process

[0042]

[0043]As can be seen from the data of table 4: (1) select 200 order calcium carbonates for use, when the add-on is 7.5%+guar gum 0.08%+anion trapping agent 0.2%, the retention rate is 30.5%, which is higher than the original process retention rate. The sticking rate has been improved by 15...

Embodiment 2

[0045] Select 200 mesh sheet-shaped calcium carbonate, join in the mixed slurry of tobacco flakes by 10% of raw material consumption, after stirring for 30 minutes under the powerful electromagnetic stirrer; After diluting the anion accelerant 10 times, press 0.3% consumption respectively Add it into the slurry and stir evenly, then dilute the guar gum to 0.1% concentration, add 0.15% into the slurry and stir evenly; according to 65±3g / m 2 Quantitatively copy the film and test its ash value, filler retention rate, and water absorption performance. Compared with the original process of 800 mesh.

[0046] Table 5 Comparison of 200 mesh calcium carbonate with the current process

[0047]

[0048] As can be seen from the data in Table 5: (1) after adding fillers in the slurry, the water absorption performance of the substrate is greatly improved; (2) 200 mesh calcium carbonate is selected, and the addition is 10%+guar gum 0.15% + When the anion scavenger is 0.3%, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com