Method for preparing poly-organic silsesquioxane microsphere

A technology of sesquioxane and polyorganosilicon, which is applied in the field of preparing polyorganosilsesquioxane microspheres, can solve the problems of cumbersome steps and achieve the effects of simple process, good spherical shape and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

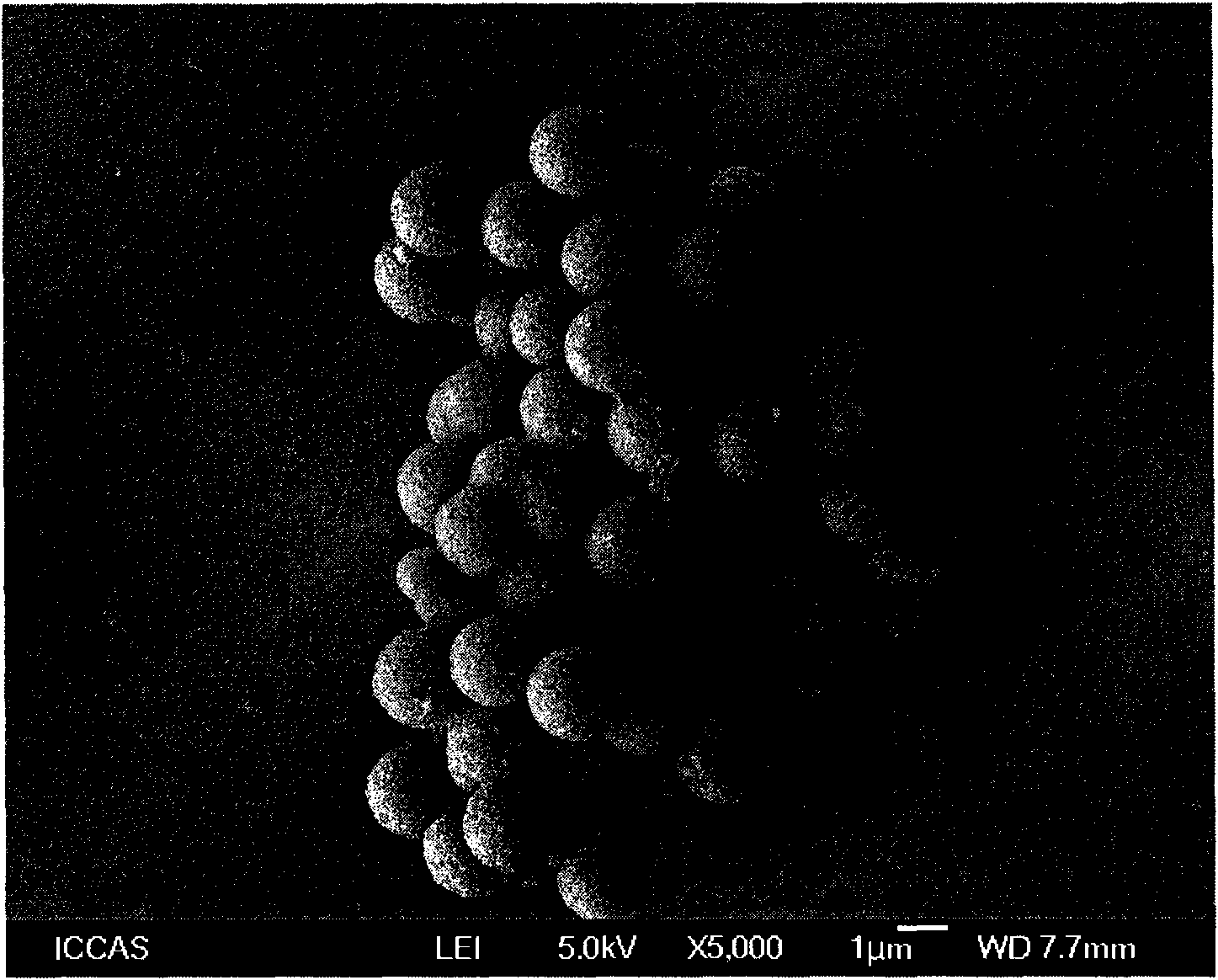

[0016] Embodiment 1, preparation polyorganosilsesquioxane microsphere

[0017] Mix 70ml of water with 10ml of ethanol, and slowly add 4ml of CH under stirring 3 Si(OCH 3 ) 3 , fully stirred to obtain a clear solution, adding 0.1ml of ammonia water with a mass percentage concentration of 28% to it, stirring continuously for 3 hours, and the silicone resin microspheres obtained after standing for 1 hour precipitated to the bottom of the reactor. Separated by filtration, washed with deionized water, and dried to obtain 1.65 g of methyl silicone resin microspheres with a particle size of 0.6-1 μm, such as figure 1 shown.

Embodiment 2

[0018] Embodiment 2, preparation polyorganosilsesquioxane microsphere

[0019] Take 40ml of water, slowly add 5ml of CH under stirring 3 Si(OCH 3 ) 3 , fully stirred to obtain a clear solution, adding 0.4ml of ammonia water with a mass percentage concentration of 28% to it, stirring continuously for 4 hours, and the silicone resin microspheres obtained after standing for 1 hour precipitated to the bottom of the reactor. Separated by filtration, washed with deionized water, and dried to obtain 2.1 g of methyl silicone resin microspheres with a particle size of 1.5-2 μm, such as figure 2 shown.

Embodiment 3

[0020] Embodiment 3, preparation polyorganosilsesquioxane microsphere

[0021] Mix 70ml of water with 10ml of ethanol, and slowly add 4ml of CH under stirring 3 Si(OCH 3 ) 3 , fully stirred to obtain a clear solution, adding 0.36ml of ammonia water with a mass percentage concentration of 28% to it, stirring continuously for 3 hours, and the silicone resin microspheres obtained after standing for 1 hour precipitated to the bottom of the reactor. Separated by filtration, washed with deionized water, and dried to obtain 1.6 g of methyl silicone resin microspheres with a particle size of 0.5 μm, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com