Method for dividing hexahedral mesh of piston of internal-combustion engine

A hexahedron and internal combustion engine technology, applied in image data processing, 3D modeling, instruments, etc., can solve problems affecting the division of piston hexahedron units, affecting mesh quality, and insufficient recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method for dividing the hexahedral grid of the internal combustion engine piston disclosed by the present invention will be specifically described below in conjunction with the accompanying drawings.

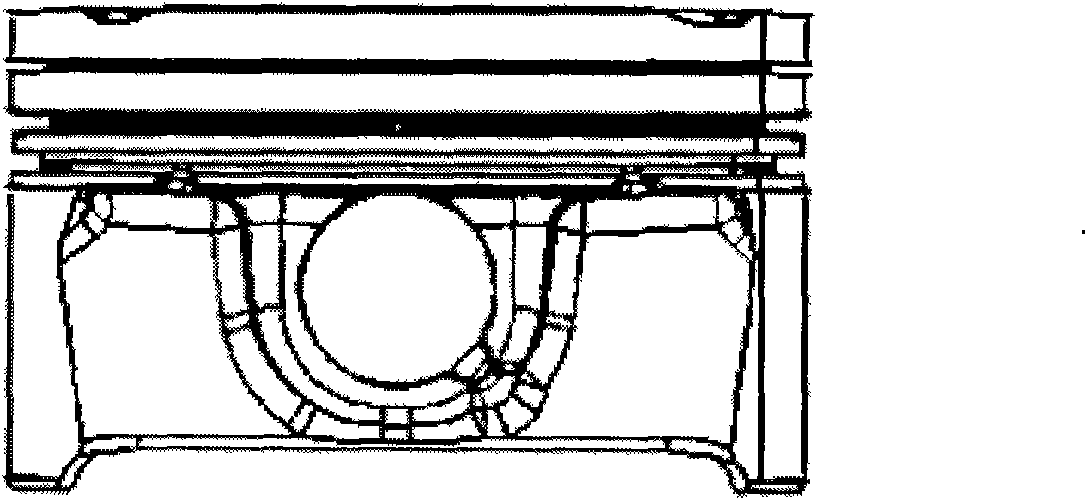

[0023] first step, such as figure 1 As shown, the three-dimensional geometric model of the piston is established first. The establishment of the model can use commonly used commercial 3D software, such as Pro / E, CATIA, UG.

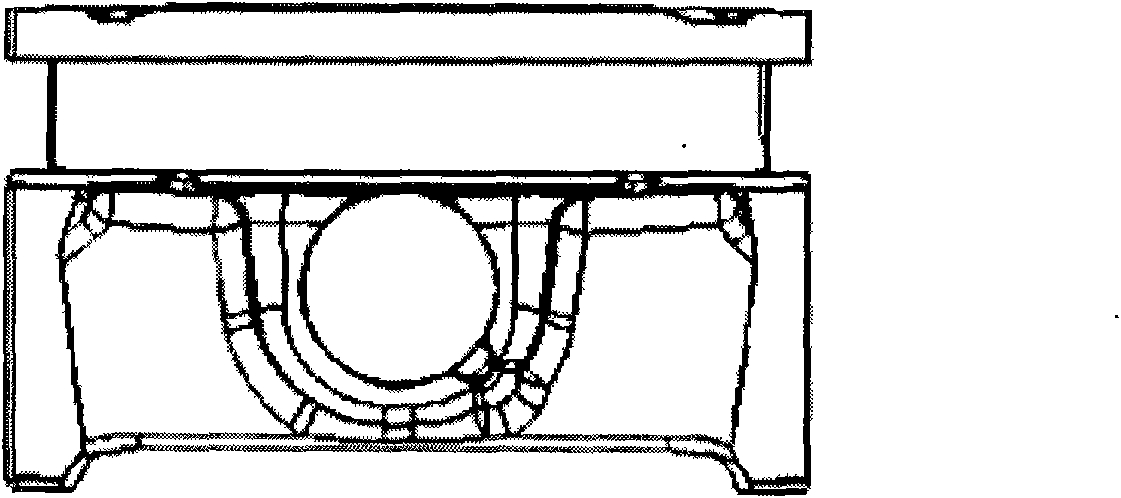

[0024] The second step, such as figure 2 As shown, remove the piston ring land. This step can be realized by the 3D software mentioned in the first step. Due to different models, the number of piston ring banks is also different. Regardless of model, remove all lands between the first land and the last groove. In this embodiment, the second and third lands are removed.

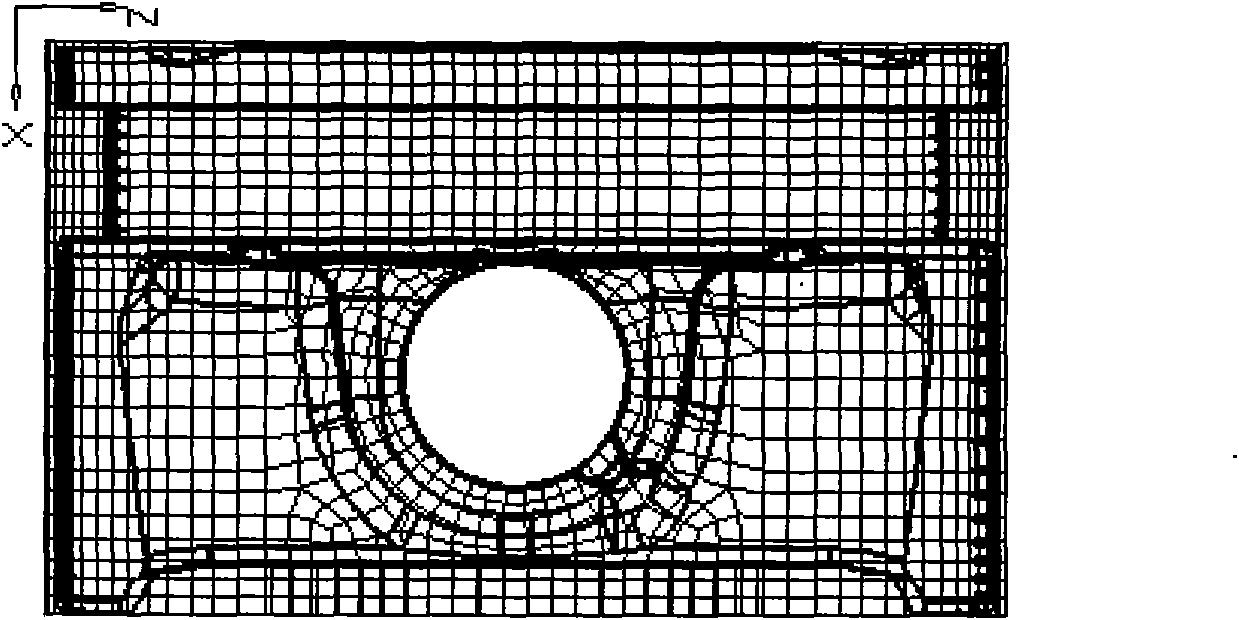

[0025] The third step, such as image 3 As shown, for the initial topology of the piston with the ring bank removed, the initial topology is to use the principle of maximu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com