Production device of broad width PVA polarized light film

A polarizing film and production equipment technology, applied in the direction of polarizing elements, optics, optical elements, etc., to achieve the effects of low scrap rate, precise heating temperature, and easy control of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

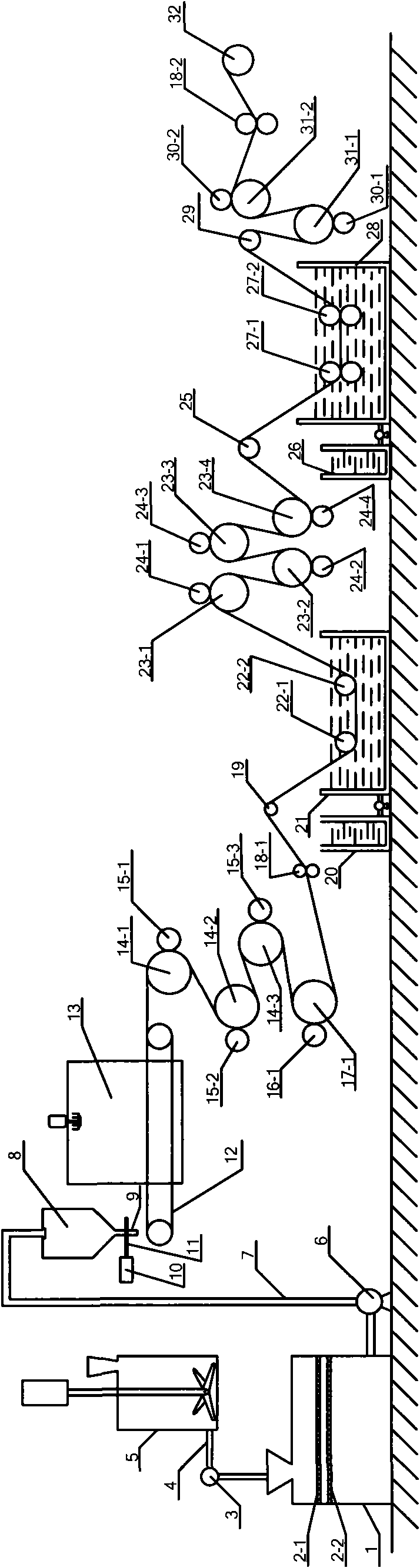

[0015] like figure 1 As shown, the production equipment of PVA polarizing film includes film making equipment and post-processing equipment.

[0016] The film-making equipment includes stirring tank 5, liquid storage tank 1, buffer tank 8, regulating motor 10, crawler conveyor device 12, oven 13, film-making heating roller group, film-making shaping roller group, and film-making traction device 18-1.

[0017] The top of the stirred tank 5 is provided with a feeding port, and the lower part is provided with a discharge port. The top of the liquid storage tank 1 is provided with a feed port, and the lower part is provided with a liquid outlet. The liquid storage tank 1 is sequentially provided with a first-stage filter The net 2-1 and the secondary filter screen 2-2, the primary filter screen 2-1 and the secondary filter screen 2-2 are arranged horizontally, and the mesh number of the primary filter screen is smaller than that of the secondary filter screen. The discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com