Standard solution used for electrolytic analyzer linear calibration

An electrolyte analyzer and standard solution technology, which is applied in the field of value transfer, can solve the problems of false positive test results, lack of wide applicability, and lack of accurate determination of solution concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

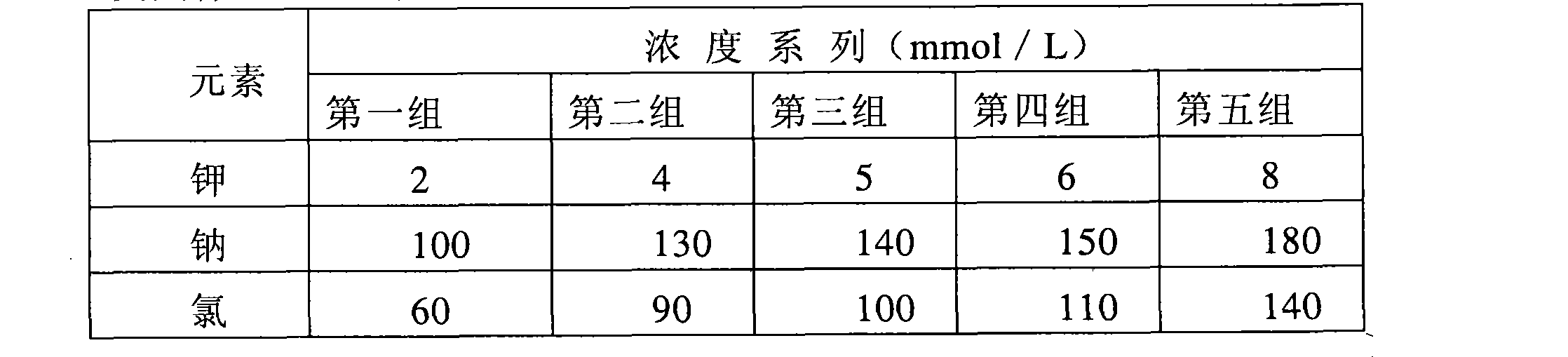

[0072] The standard solution for linearity verification of electrolyte analyzer consists of 5 groups of solutions:

[0073] 1) The first group of solutions weighed 3.38968g of sodium chloride standard substance, 0.14910g of potassium chloride standard substance, and 2.22570g of sodium carbonate standard substance in a beaker with an electronic balance of 1 / 100,000. Dissolved and transferred to a 1L volumetric flask. Weigh 6.3000g of 3-morpholinepropanesulfonic acid into a beaker, fully dissolve with ultrapure water, transfer to the same volumetric flask, blend evenly with ultrapure water and dilute to 1L.

[0074] 2) The second group of solutions weighed 5.02608g of sodium chloride standard substance, 0.29820g of potassium chloride standard substance, and 2.33169g of sodium carbonate standard substance in a beaker using an electronic balance of one-hundredth of a million. Dissolved and transferred to a 1L volumetric flask. Weigh 6.5000g of 3-morpholinepropanesulfonic acid in...

Embodiment 2

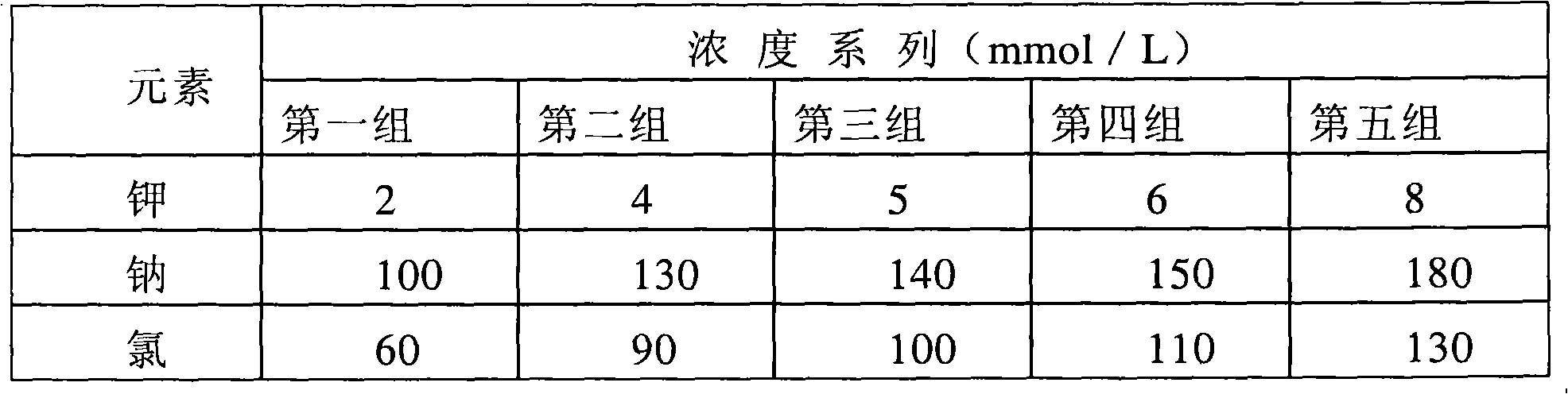

[0082] The standard solution for linearity verification of electrolyte analyzer consists of 5 groups of solutions:

[0083] 1) The first group of solutions weighed 3.38968g of sodium chloride standard substance, 0.14910g of potassium chloride standard substance, and 2.22570g of sodium carbonate standard substance in a beaker with an electronic balance of 1 / 100,000. Dissolved and transferred to a 1L volumetric flask. Weigh 6.3000g of 3-morpholinepropanesulfonic acid into a beaker, fully dissolve with ultrapure water, transfer to the same volumetric flask, blend evenly with ultrapure water and dilute to 1L.

[0084] 2) The second group of solutions weighed 4.47085g of sodium chloride standard substance, 0.26093g of potassium chloride standard substance, and 2.30520g of sodium carbonate standard substance in a beaker using an electronic balance of one-hundredth of a million. Dissolved and transferred to a 1L volumetric flask. Weigh 6.5000g of 3-morpholinepropanesulfonic acid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com