A kind of pure alkyd paint and preparation method thereof

An alkyd paint and odor-cleaning technology, applied in the paint field, can solve problems affecting health and other problems, achieve the effect of reducing irritating odor and breathing freely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

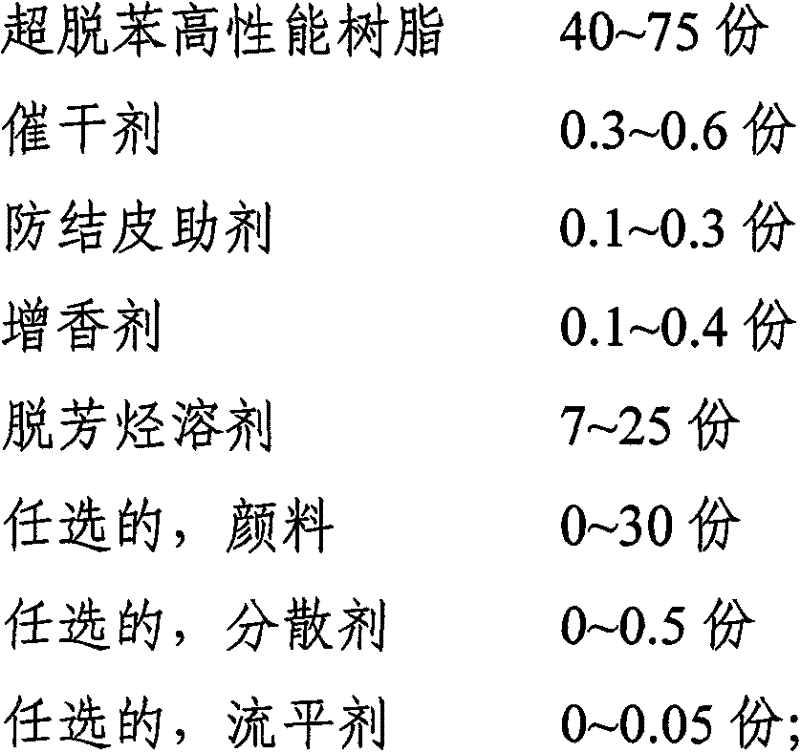

Method used

Image

Examples

Embodiment 1

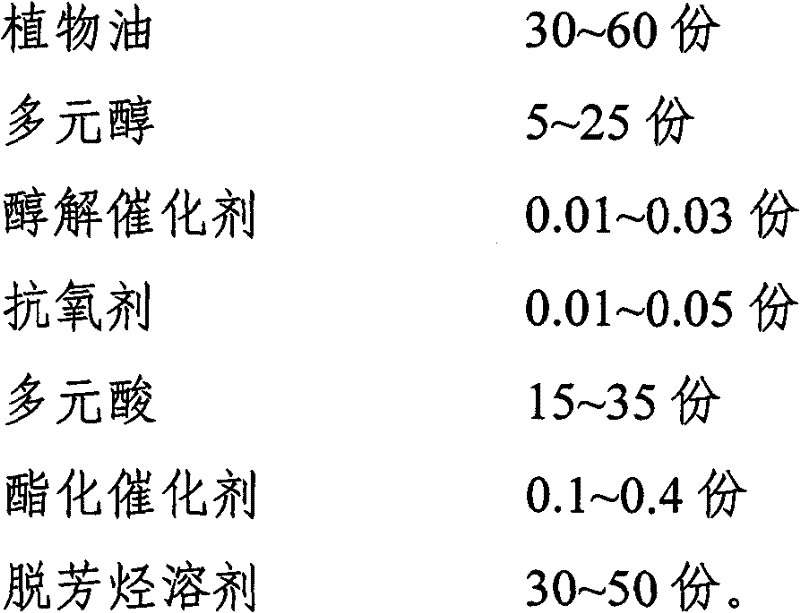

[0075] The composition and proportioning of the ultra-benzene-removing high-performance resin of the present invention are as follows:

[0076] composition

Feeding amount (kg)

400

78

0.2

S-680 Antioxidant

0.3

132

BC-98 esterification catalyst

1.5

dearomatization solvent

385

total

1000

[0077] The preparation method of self-made super-removing benzene high-performance resin among the present invention is as follows:

[0078] 1) In the water separator, use solvent as the bottom;

[0079] 2) Put 400KG of soybean oil, 78KG of pentaerythritol, 0.2KG of lithium hydroxide and 0.3KG of antioxidant into the reaction kettle in sequence, and feed CO 2 gas;

[0080] 3) Stir and heat up at a constant speed, keep the temperature at about 240°C for the alcoholysis reaction, and after keeping warm for 1 ...

Embodiment 2

[0099] The preparation process of the ultra-benzene-removing high-performance resin in this example is the same as that in Example 1.

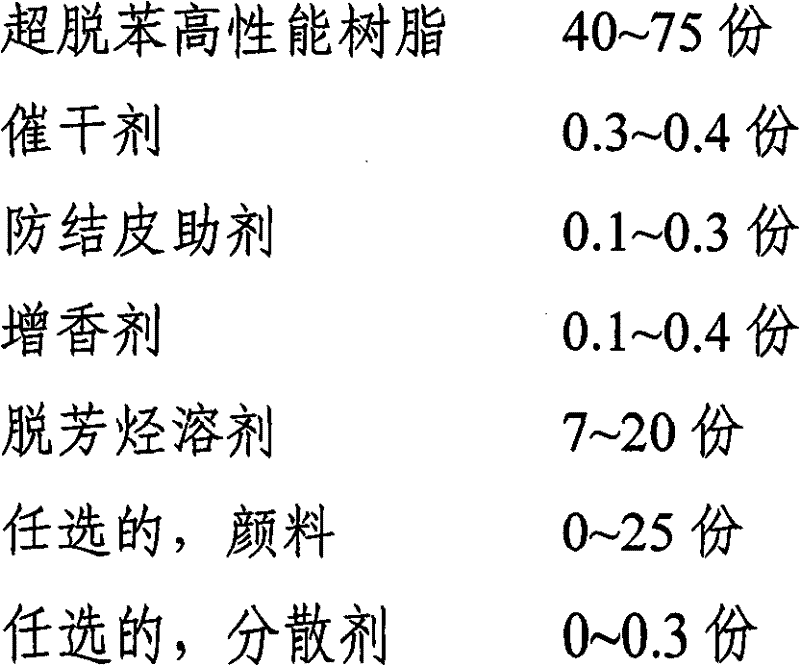

[0100] The clean taste alkyd paint of the present invention comprises following components:

[0101] components

Feeding amount (kg)

Titanium dioxide

79

38

3

32

Ultra-debenzene high-performance resin

687

High-efficiency drier

5

2

1% silicone oil solution (by weight)

3

1

dearomatization solvent

150

total

1000

[0102] The preparation method of above-mentioned pure taste alkyd coating is:

[0103] 1) Mixing:

[0104] First add about 100 kg of part of the resin in the formula to the bottom of the mixing tank, slowly add 32KG of phthalocyanine blue under low-speed stirring, and then add 300KG of super-benzene-f...

Embodiment 3

[0114] The composition and proportioning of the ultra-benzene-removing high-performance resin of the present invention are as follows: soybean oil 35kg, glycerin 14kg, diethylene glycol 10kg, lithium hydroxide 0.01kg, XP-60 0.05kg, phthalic anhydride 8kg, maleic acid 5kg of dianhydride, 0.4kg of BC-98, and 37.54kg of dearomatization solvent.

[0115] Its preparation method is as follows:

[0116] 1) In the water separator, use solvent as the bottom;

[0117] 2) Prepare soybean oil, glycerin, diethylene glycol, lithium hydroxide and antioxidant XP-60 in the reaction kettle in sequence according to the above ratio, and feed CO 2 gas;

[0118] 3) Stir and heat up at a constant speed, keep the temperature at about 240°C for the alcoholysis reaction, and after keeping warm for 1 hour, measure the tolerance, and if it is qualified, it is the end point of alcoholysis;

[0119] 4) Cool down to 170°C, add phthalic anhydride, maleic anhydride, esterification catalyst BC-98 and solvent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com