Photochemical preparation method of amphiphilic silver nanometer granules

A silver nanoparticle and amphiphilic technology, applied in the field of photochemistry, can solve the problems of troublesome post-processing process, restricting the development of photochemical methods, environmental pollution, etc., and achieve the effect of simple post-processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

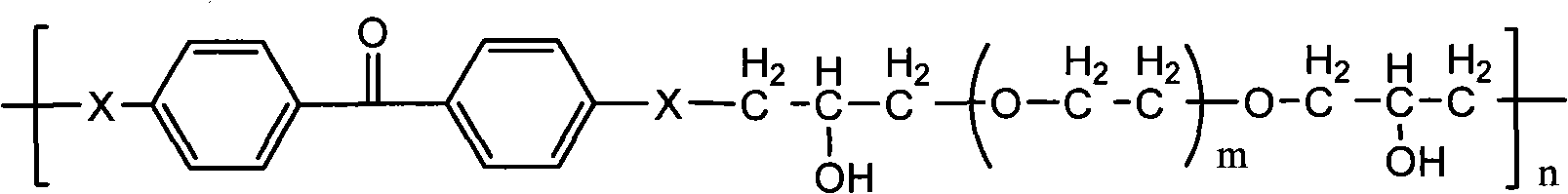

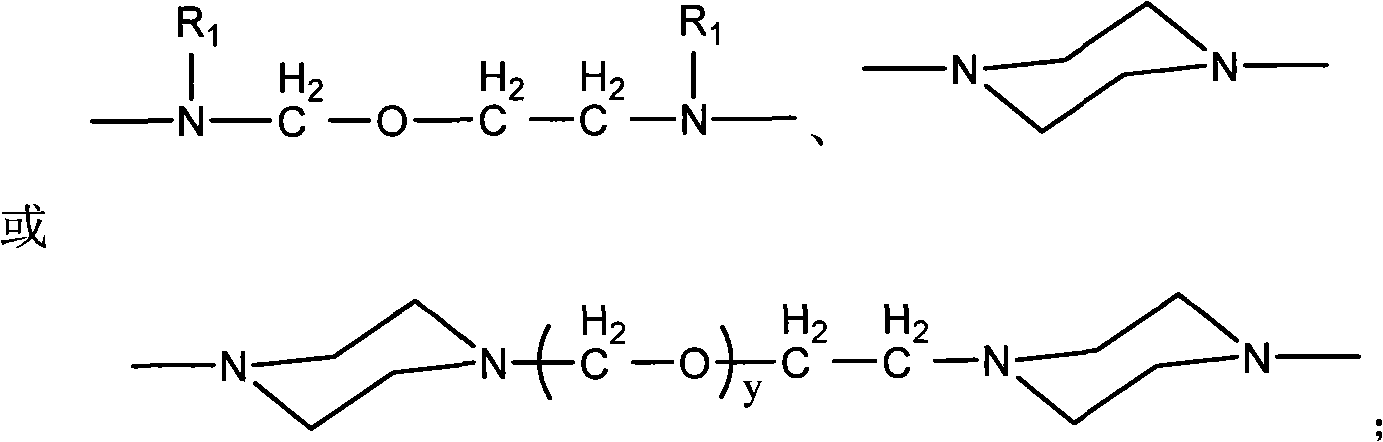

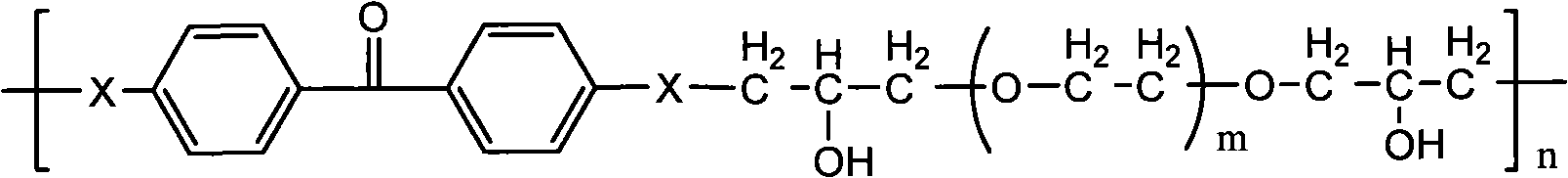

Image

Examples

Embodiment 1

[0017] 0.084g (0.04mmol) APMK is dissolved in 20ml water, then add 0.034g (0.2mmol) silver nitrate, be mixed with APMK concentration and be 2mmol / L, the mixed solution of silver nitrate concentration is 10mmol / L, then put the mixed solution in The wavelength is 365nm, and the light intensity is 2mW / cm 2 Irradiate for 20 min under a UV lamp to obtain a silver nanoparticle solution. Adjust the silver nanoparticle solution to pH 8-10, then raise the temperature to 40-50° C., centrifuge, wash with water, rinse with ethanol, and dry naturally to obtain amphiphilic silver nanoparticles with an average particle size of 20 nm.

Embodiment 2

[0019] 0.084g (0.04mmol) APMK is dissolved in 20ml water, then add 0.0034g (0.02mmol) silver nitrate, be mixed with APMK concentration and be 2mmol / L, silver nitrate concentration is the mixed solution of 1mmol / L, then put the mixed solution in The wavelength is 365nm, and the light intensity is 2mW / cm 2 120min under the ultraviolet lamp irradiation, obtains the silver nano particle solution. Adjust the silver nanoparticle solution to pH 8-10, then raise the temperature to 40-50° C., centrifuge, wash with water, rinse with ethanol, and dry naturally to obtain amphiphilic silver nanoparticles with an average particle size of 20 nm.

Embodiment 3

[0021] 0.126g (0.06mmol) APMK is dissolved in 20ml water, then add 0.0034g (0.02mmol) silver nitrate, be mixed with APMK concentration and be 3mmol / L, the mixed solution of silver nitrate concentration is 1mmol / L, then put the mixed solution in The wavelength is 365nm, and the light intensity is 2mW / cm 2 Irradiate for 3 hours under an ultraviolet lamp to obtain a silver nanoparticle solution. Adjust the silver nanoparticle solution to pH 8-10, then raise the temperature to 40-50° C., centrifuge, wash with water, rinse with ethanol, and dry naturally to obtain amphiphilic silver nanoparticles with an average particle size of 20 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com