Reciprocating moving lead scoop for lead plate continuous casting machine

A continuous casting machine, reciprocating technology, used in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of uneven temperature of lead liquid and inconsistent mechanical strength of lead plates, and achieve consistent mechanical strength and thickness. , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

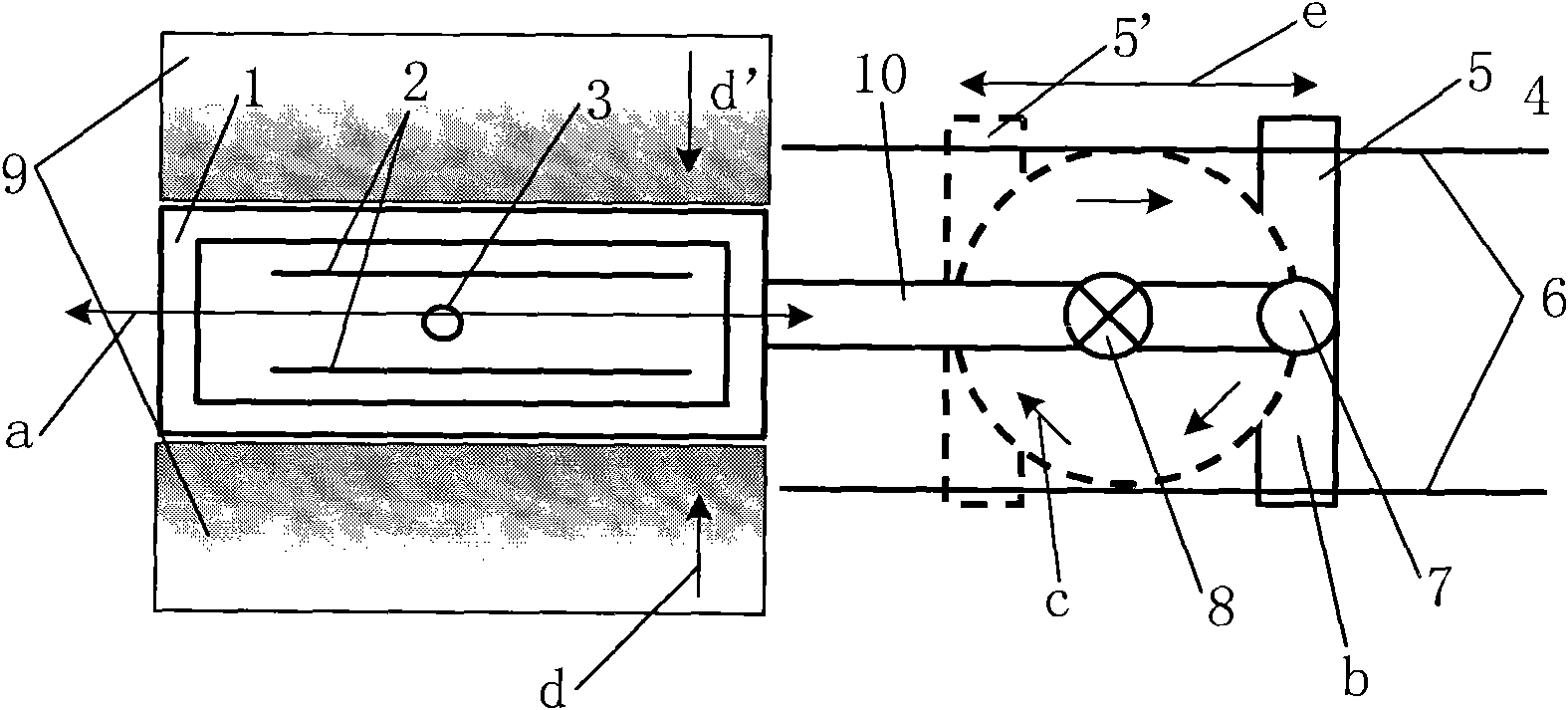

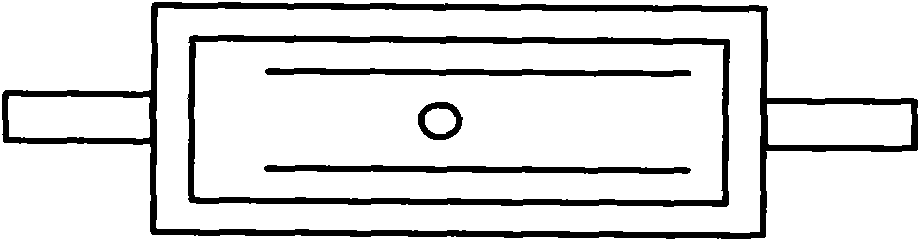

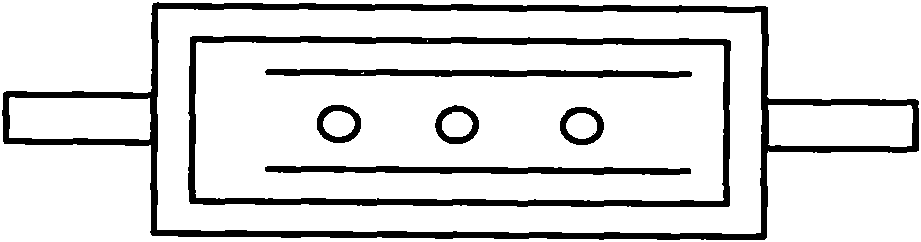

[0021] This embodiment provides a reciprocating mobile lead spoon for a lead plate continuous casting machine, which is used in the lead plate continuous casting machine to add lead liquid to the casting roller, so that the temperature of the lead liquid added to the casting roller is more uniform. Such as figure 1 Shown, this mobile lead spoon includes:

[0022] Lead spoon body 1, heating tube 2, lead liquid output tube 3, rotating arm 4, guide groove 5, guide shaft 6, movable bearing 7 and driving device 8;

[0023] Wherein, the guide groove 5 is movably arranged on the guide shaft 6, and the guide shaft 6 is generally two shafts arranged in parallel. , the rotating arm 4 is arranged on the rotating shaft of the driving device 8, one end of the rotating arm 4 is movably arranged in the guide groove 5 through the movable bearing 7, and the other end of the rotating arm 4 is connected to the lead spoon body 1, which can be connected with the lead spoon body through the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com