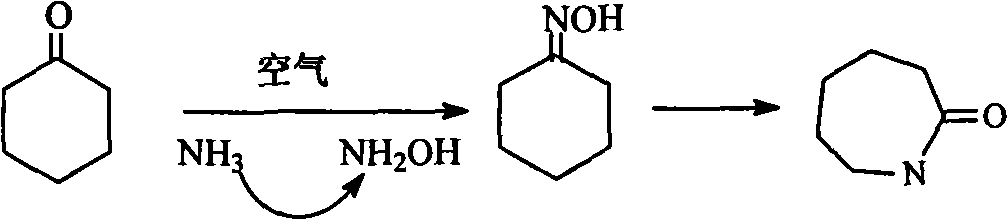

Catalyst for synthesizing caprolactam in one step by ammoxidation of cyclohexanone and preparation and application method thereof

A caprolactam and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of separation of intermediate products and energy consumption, and solve the problems of equipment corrosion and environmental pollution, low production cost, The effect of long preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of supported catalyst, the steps are as follows:

[0029] In the first step, get tetraethyl orthosilicate (TEOS), aluminum sec-butoxide, and dehydrated ethanol and place them in a 100ml three-necked flask, the molar ratio of which is tetraethyl orthosilicate: aluminum sec-butoxide: dehydrated ethanol=0.93 : 1:8 After stirring mechanically at room temperature for 10 minutes, place the there-necked flask in a water bath at 70°C, slowly add aqueous hydrochloric acid solution with a mass concentration of 12% until the pH of the reaction system is 3, stir in a constant temperature water bath at 70°C for 1.5 hours, take out Distillation under reduced pressure was performed to remove water, ethanol and butanol.

[0030] In the second step, the material obtained in the first step is calcined in a tube furnace at a high temperature of 550° C. for 5 hours in an oxygen atmosphere to obtain a composite oxide of silicon oxide and aluminum oxide.

[0031] In the thir...

Embodiment 2

[0035] Step is the same as Example 1, and the difference is that in the first step, the mol ratio of tetraethyl orthosilicate (TEOS), aluminum sec-butoxide, dehydrated alcohol is 0.73: 1: 8; Get 0.23g mass concentration in the 3rd step It is 85% phosphoric acid, dissolved in 1.45g of distilled water to form an impregnation solution. In the fifth step, 1.90 g of a supported bifunctional catalyst product for the one-step synthesis of caprolactam from cyclohexanone was obtained.

Embodiment 3

[0037] Step is the same as Example 1, and difference is that, in the first step, the mol ratio of tetraethyl orthosilicate (TEOS), aluminum sec-butoxide, dehydrated alcohol is 1.13: 1: 8; Get 1.33g mass concentration in the 3rd step It is 85% phosphoric acid, dissolved in 1.29g of distilled water to form an impregnation solution. In the fifth step, 2.83 g of a supported bifunctional catalyst product for the one-step synthesis of caprolactam from cyclohexanone was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com