Three-stage brushless micro gas turbine electricity generation grid-connecting device and grid connecting method

A micro, gas turbine technology, applied in the direction of single grid parallel feeding arrangement, etc., can solve the problems of slow power generation grid connection, grid shock, power system voltage drop, etc., and achieve the effect of improving power generation quality, reducing shock, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

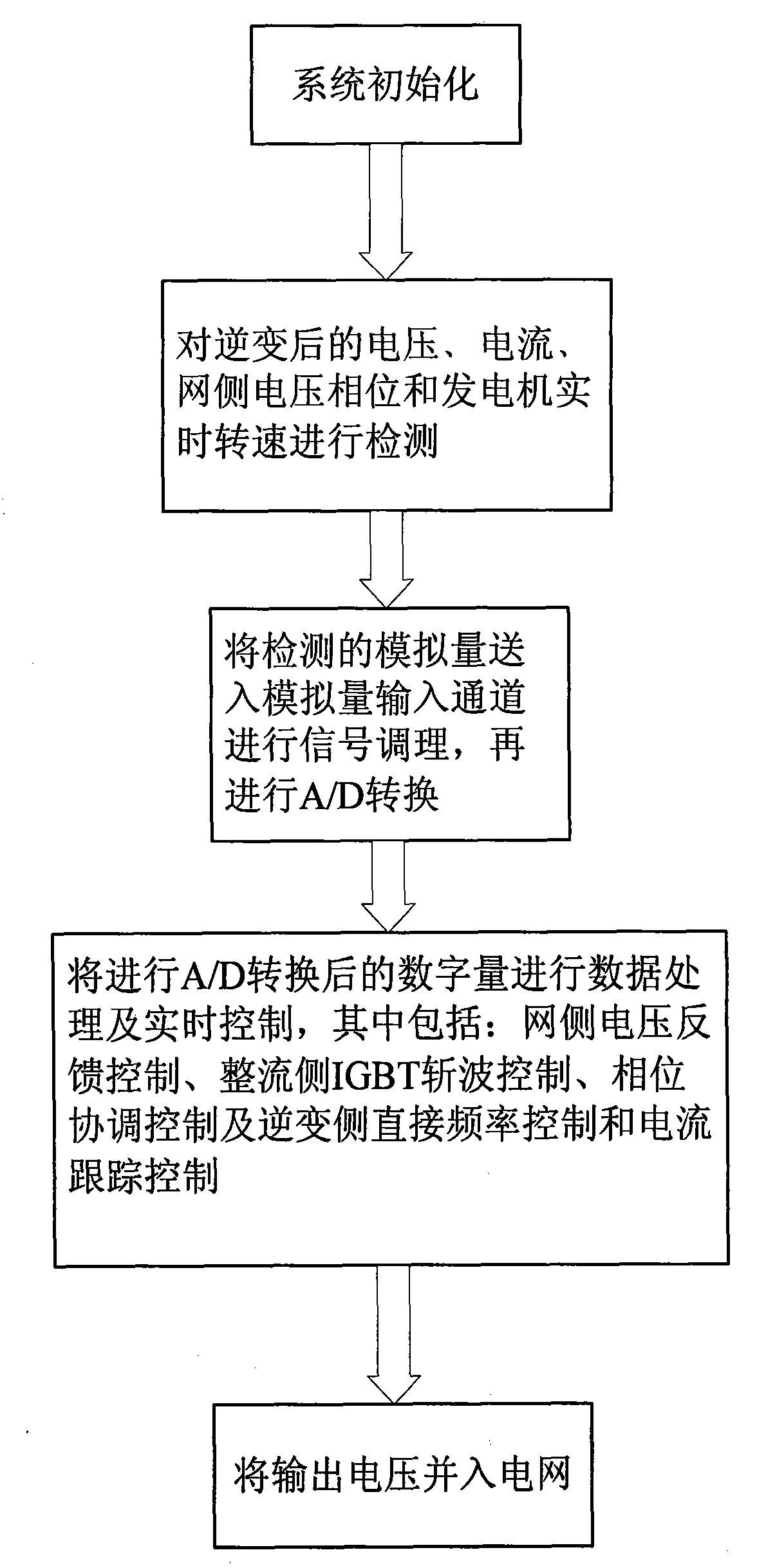

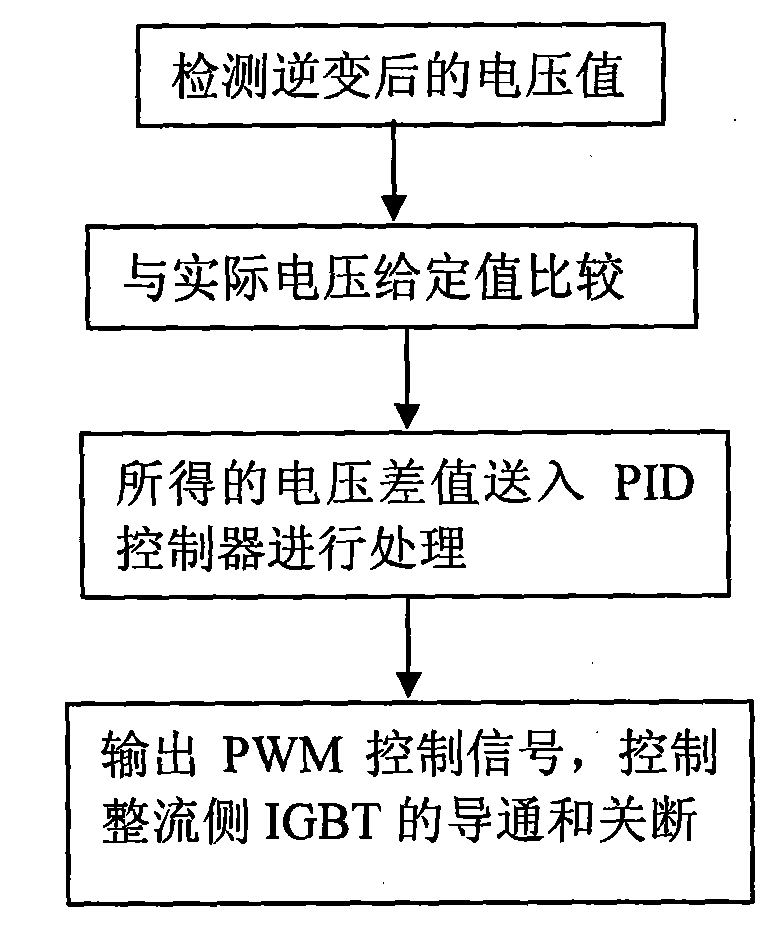

Method used

Image

Examples

Embodiment

[0074] Now take the grid connection of 75KW medium frequency micro gas turbine as an example.

[0075] The 75KW medium frequency micro gas turbine is a three-phase four-wire system, but the unit does not lead out the neutral line to the load; therefore, the voltages mentioned below are all line voltages. Among them, the rated voltage is 208V, the rated power is 75KW, the maximum power is 82.5KW, the rated power factor is 0.7, and the rated frequency is 400Hz. The DC power supply uses a 27V battery.

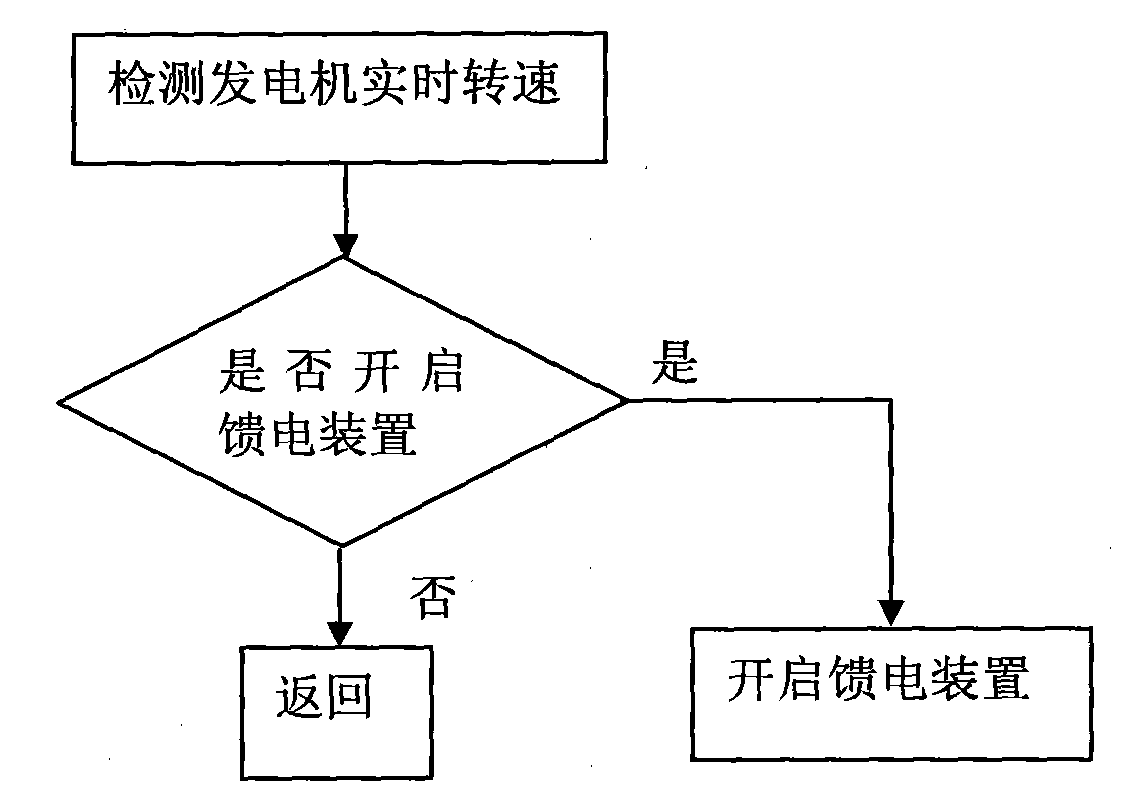

[0076] The output current feedback of the intermediate frequency micro gas turbine, the transformation ratio of the current transformer is 90:1; the output voltage feedback, the transformation ratio of the voltage measurement transformer is 17:1. In order to shorten the grid-connection time of generator power generation, appropriate electric energy is fed from the grid side through the feeder device according to the real-time speed, which improves the response speed of power gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com