Terminal strip for electric locomotive hauling transformer

A technology for traction transformers and electric locomotives, applied in the direction of transformers/inductor coils/windings/connections, etc., can solve problems such as inconvenient installation and maintenance, low service life, poor insulation degree, etc., and achieve reduced quality control points and long service life , Improve the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

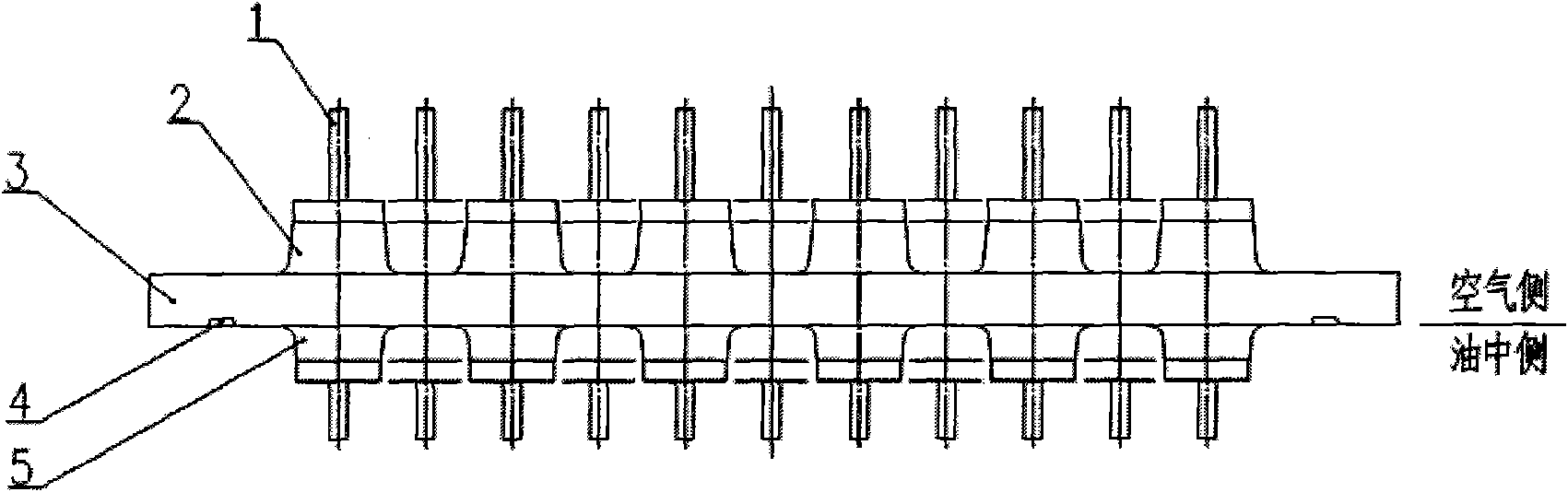

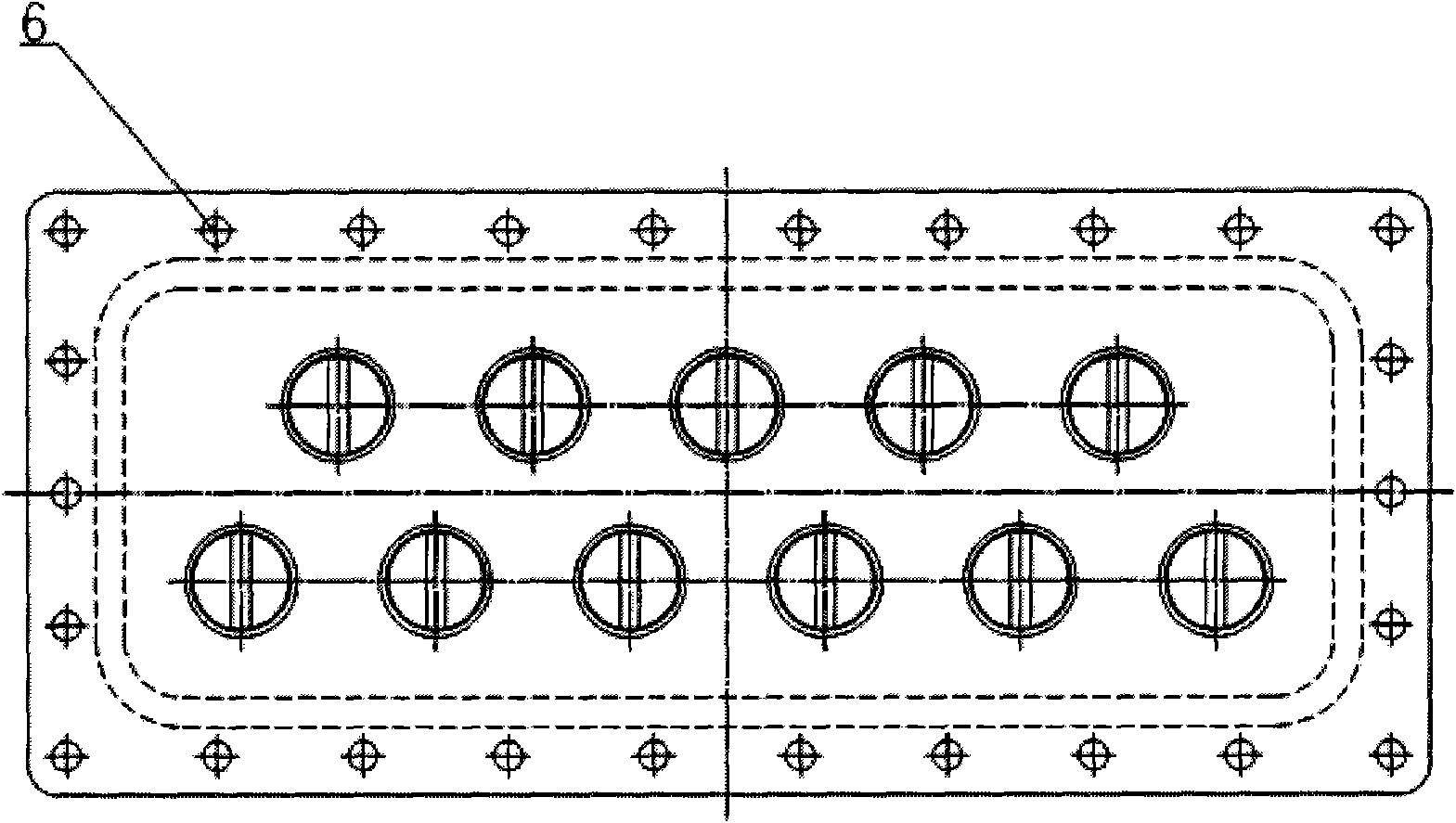

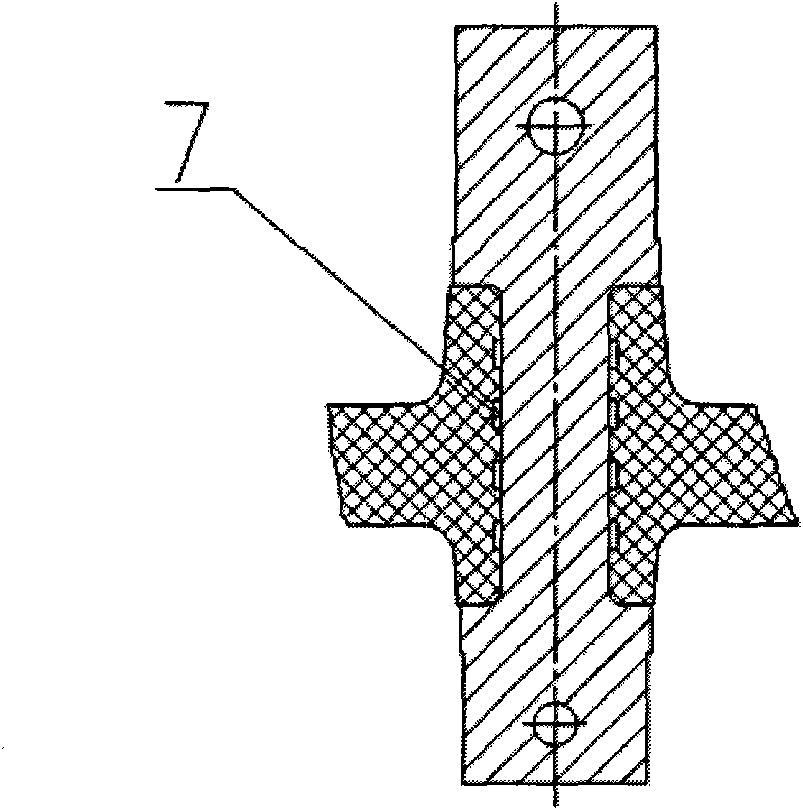

[0014] like Figure 1~3 As shown, a terminal block for an electric locomotive traction transformer according to the present invention is composed of a connecting terminal 1 , an air side insulating post 2 , a mounting flange 3 and an oil mid-side insulating post 5 . The terminal block 1 is made of high-quality copper, the two ends are plate-shaped, and the middle is a cylindrical structure, which ensures reliable and effective solidification during epoxy resin pouring and facilitates user wiring. It runs through the integral structure; air side insulation column 2, installation method Both the blue 3 and the insulating column 5 on the middle oil side are integrally formed by vacuum casting of epoxy resin, so that they have excellent dielectric strength and mechanical strength; There are a plurality of silicone rubber buffer rings 7 with superior elasticity (4 to 6, and 4 are used in this embodiment), which not only ensure the role of buffering and crack prevention when the epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com