Method and device for preparing carbon nanotube film

A technology of carbon nanotube film and nanotube film, which is applied in the field of nanomaterials, can solve the problems of affecting the structure of carbon nanotubes, cumbersomeness, and limiting the efficiency of transparent conductive carbon nanotube films, and achieve the effect of simple reaction equipment and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

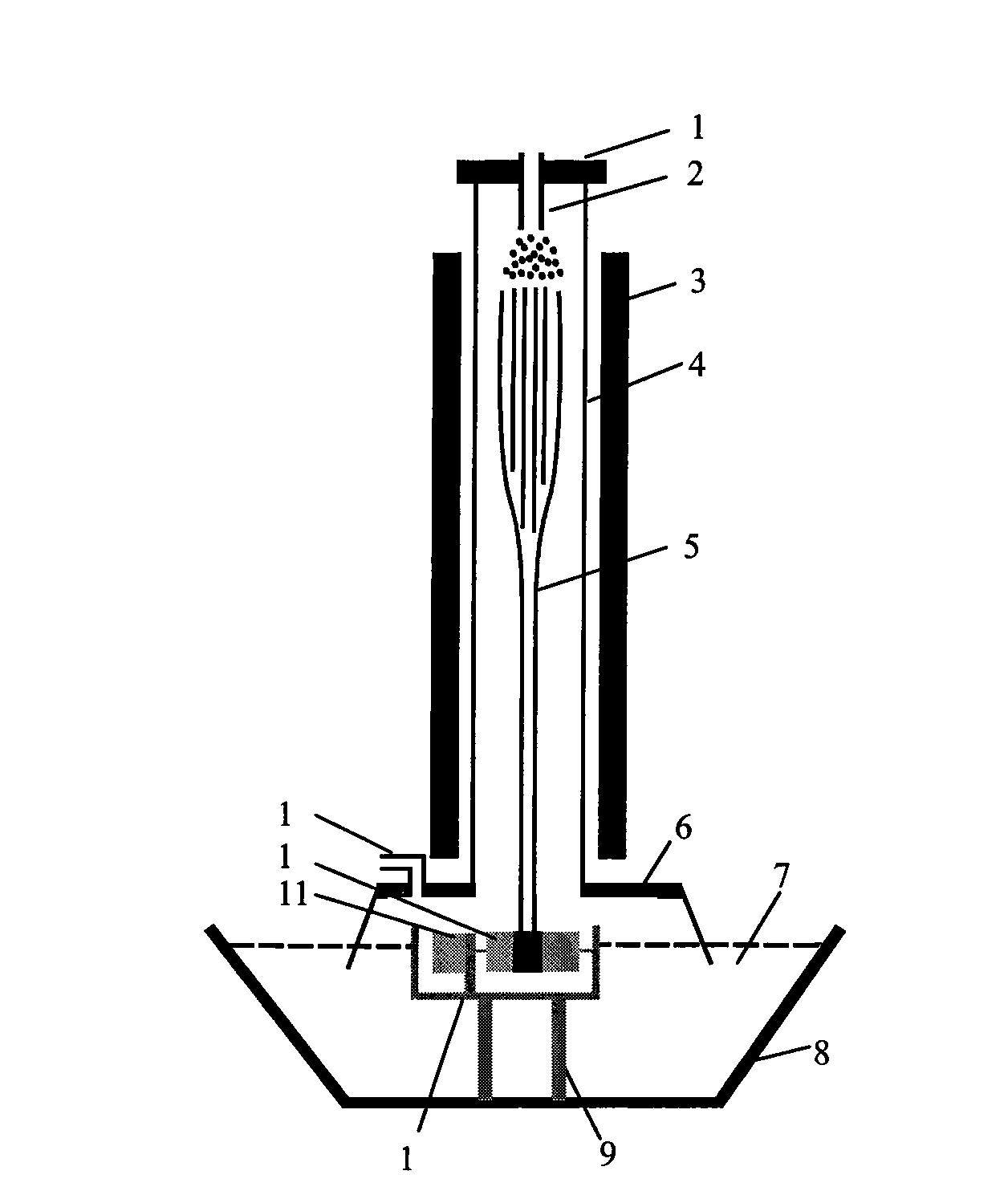

Method used

Image

Examples

Embodiment 1

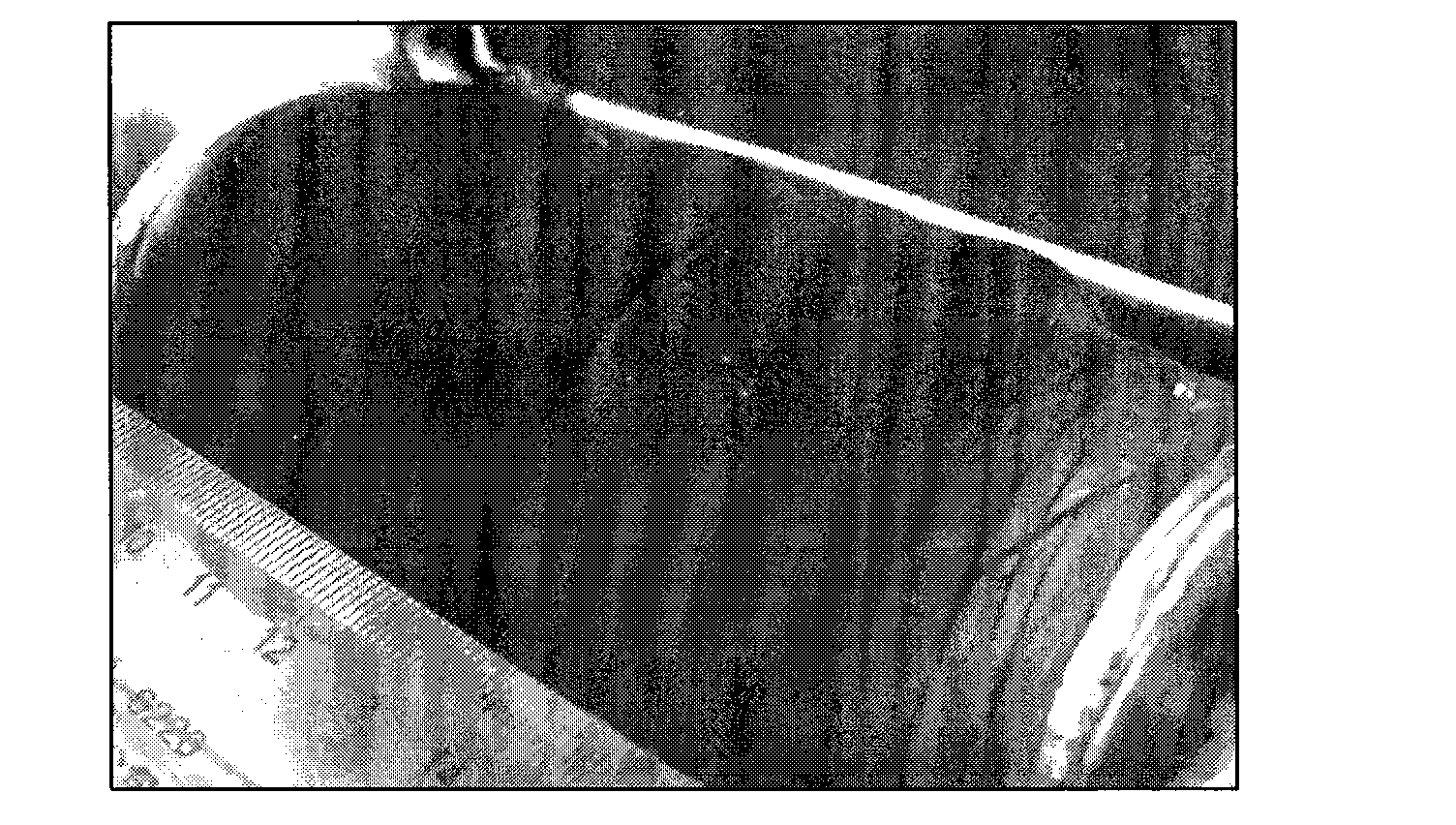

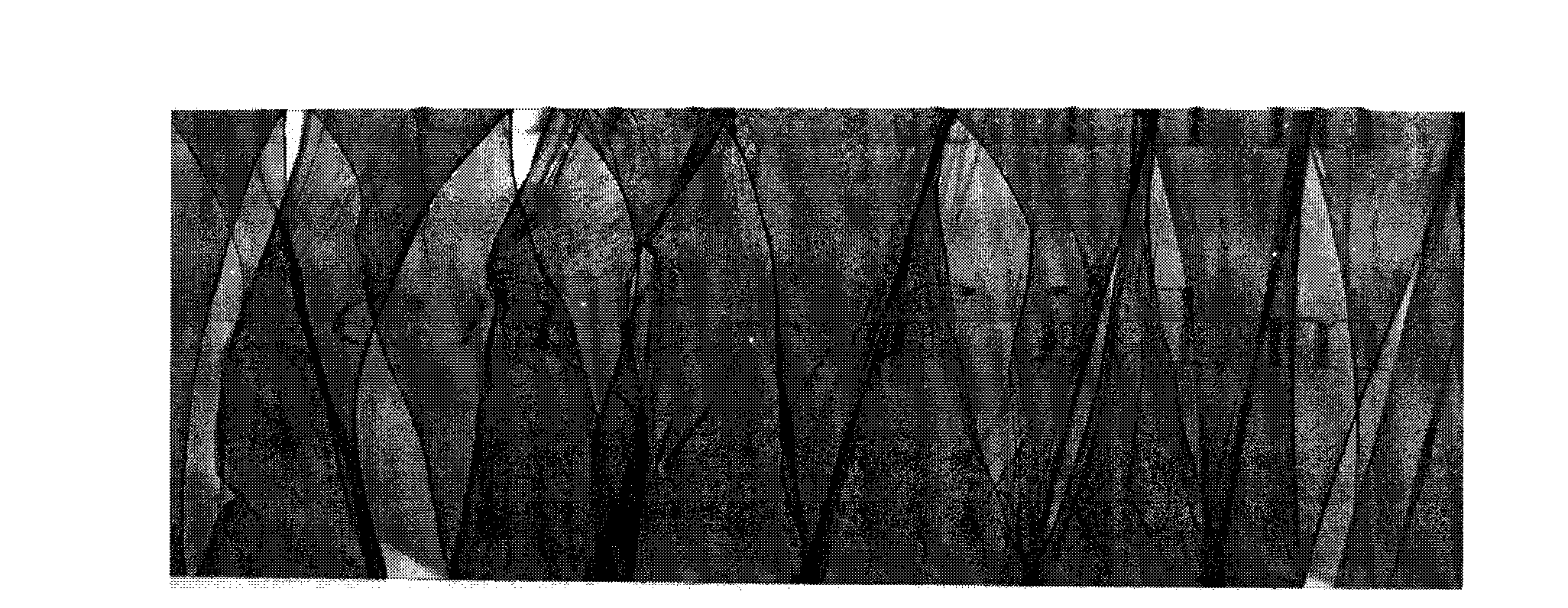

[0022] Using ethanol as carbon source and ferrocene as catalyst. Ferrocene was added to ethanol at a mass percentage of 2%. Using thiophene as a growth promoter, it was added to the solution at a mass percentage of 2%. The reactor was evacuated, 1000 ml of hydrogen per minute was introduced, and the temperature was raised to 1100 degrees. Inject the prepared solution into the reactor at a rate of 10.0 ml per hour, spin on the shaft, and spin for 1 hour. figure 2 . The continuous carbon nanofiber membrane can be detached from the spinning shaft, and the morphology is as follows image 3 . The prepared film was transparent. The transmittance of the film measured by UV-Vis spectroscopy was 65%. The conductivity of the carbon nanometer was measured by a multimeter to be 1.5×10 5 S / m. The transmission electron microscope observed that the film was composed of laminated carbon nanotubes ( Figure 4 ).

Embodiment 2

[0024] The preparation process of carbon nanotube film is the same as that of Example 1. The solution was prepared with ferrocene with a mass ratio of 0.1% and thiophene with a mass ratio of 0.4%. It was observed that a continuous carbon nanotube film with a diameter of 1.0 cm was formed on the side of the reactor. Spinning the film at a spinning speed of 2 meters per minute for 1 hour, the carbon nanotube film can be completely untethered in the opposite direction of spinning, and the untethered film is transparent. The measured film transmittance is 70% and the conductivity is 1.0× 10 5 S / m, electron microscope observed that the film in the film was single-walled carbon nanotubes.

Embodiment 3

[0026] The preparation process of carbon nanotube film is the same as that in Example 1, with the mass percentage of 2% cobalt acetate as the catalyst, and the formation of a continuous carbon nanotube film with a diameter of 2.0 cm was observed on the side of the reactor, and the film was spun at a spinning speed of 2 meters per minute. Within hours, the spun carbon nanotube film can be dissociated, the dissociated carbon nanotube film is transparent, and the film is observed by transmission electron microscope as double-walled carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com