Lifting appliance for installing last furnace shell

A blast furnace shell and installation technology, which is applied in the field of spreaders, can solve the problems that the overall shell and appearance quality are difficult to guarantee, increase the labor intensity of workers, increase the difficulty of high-altitude operation, etc., so as to reduce the labor intensity of workers, have a simple structure, Good overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

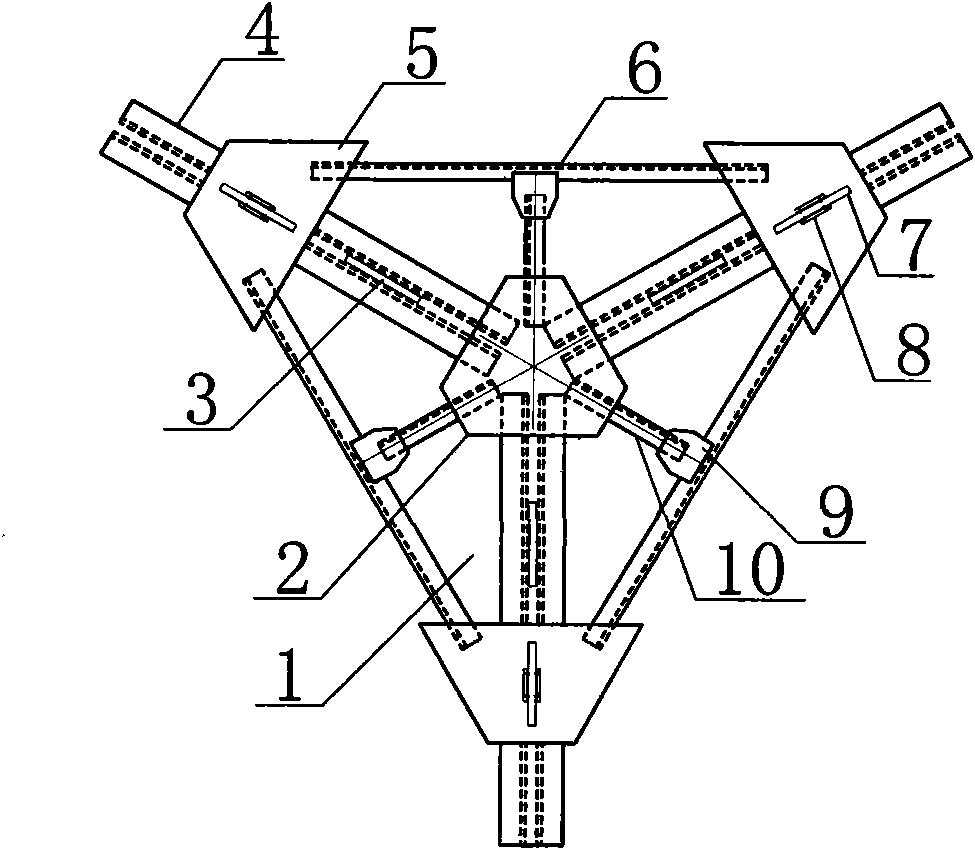

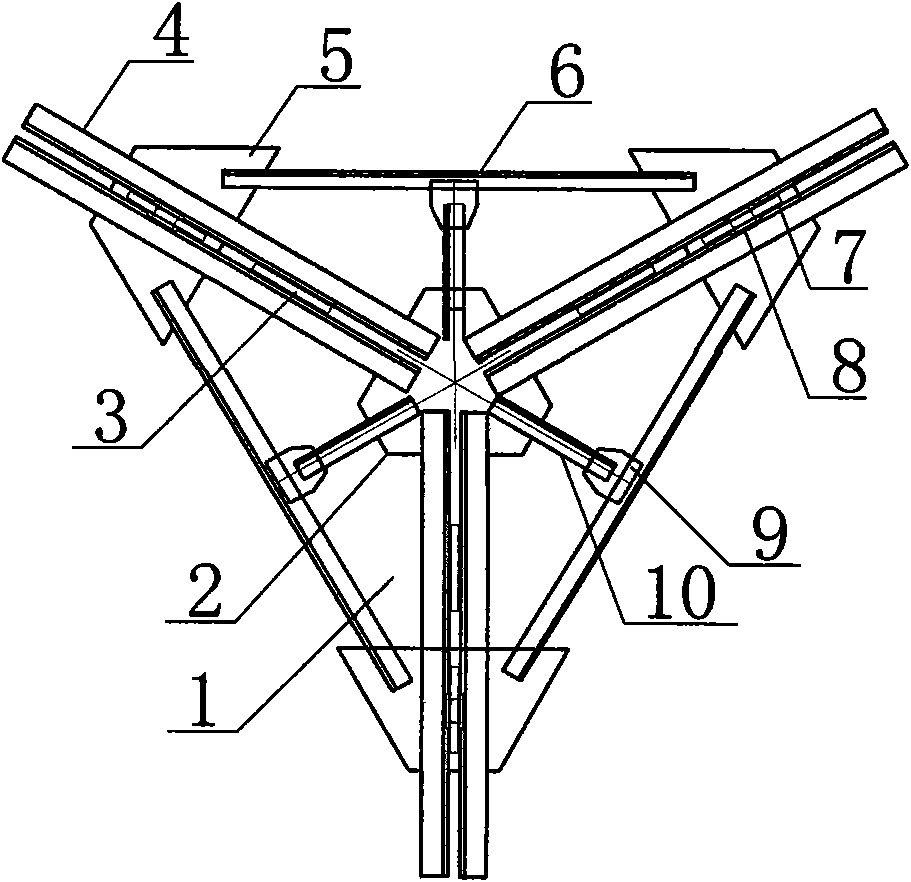

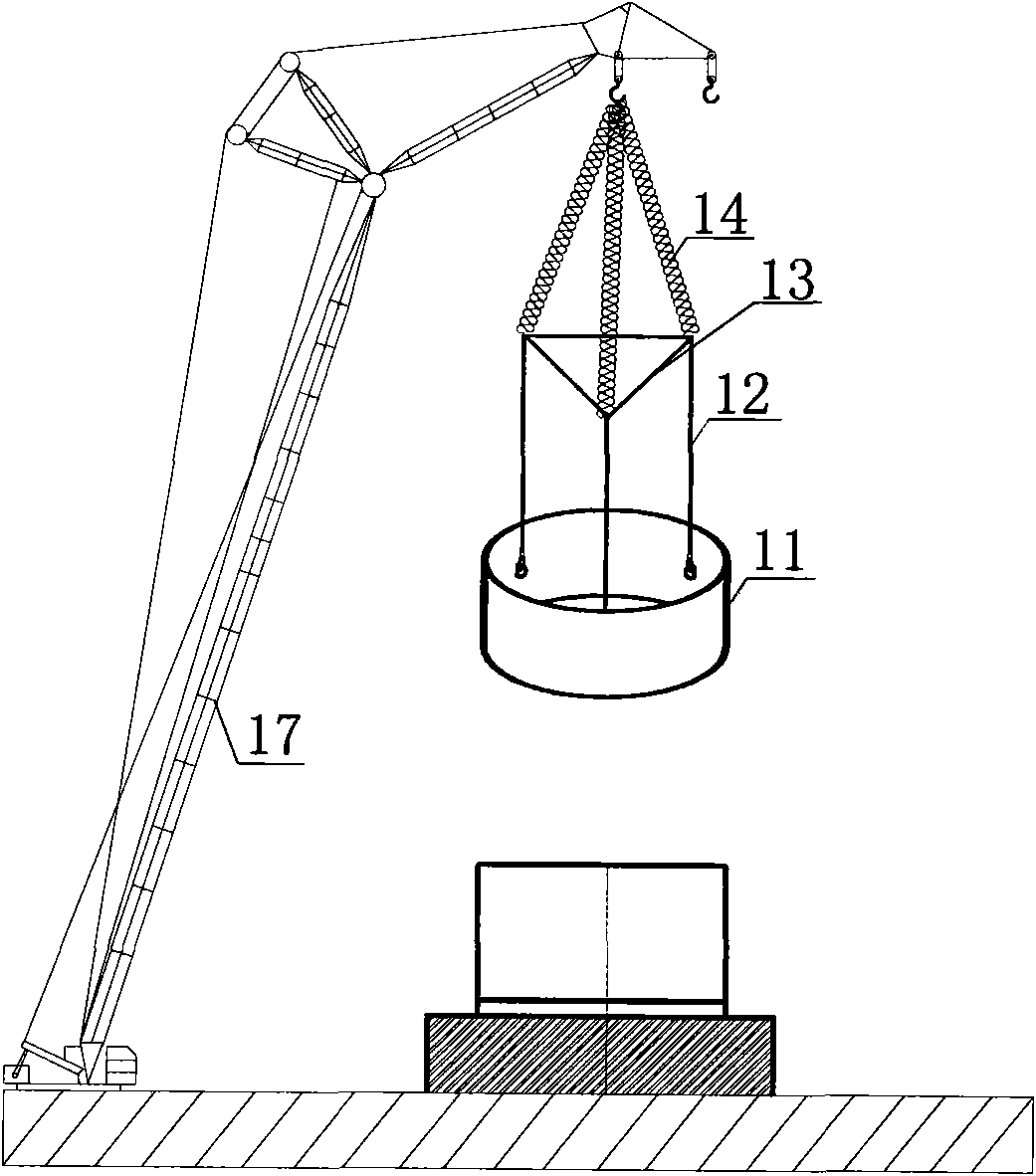

[0009] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , the spreader (1) is in the shape of an equilateral triangle, the three side supports (6) of the spreader (1) are connected through the corner connecting plates (5), and at the same time, three suspenders (4) are connected to the three corner connecting plates (5) , the suspender (4) is provided with a panel (3), the suspender (4) is connected to the corner connecting plate (5), and the lifting lug (7) passes through the suspending rod (4) and the corner connecting plate (5) to connect with it, in An upper hoisting hole (15) and a lower hoisting hole (16) are arranged on the lifting lug (7), double-sided reinforcing rings (8) are respectively arranged at the positions of the two hoisting holes, and the three-side support (6) is connected to the pull rod ( 10), the pull rod (10) and the suspender (4) are centrally connected to the triangular central connecting plate (2), and the spreader is formed as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com