Cathode structure of membrane electrode assembly of direct alcohol fuel cell and manufacturing method

A fuel cell and membrane electrode technology, which is applied to fuel cell components, fuel cells, battery electrodes, etc., can solve the problems of battery performance degradation, power density not reaching the practical level, and troubles for practical applications, etc. Minimizes loss, improves oxygen transmission efficiency, and is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

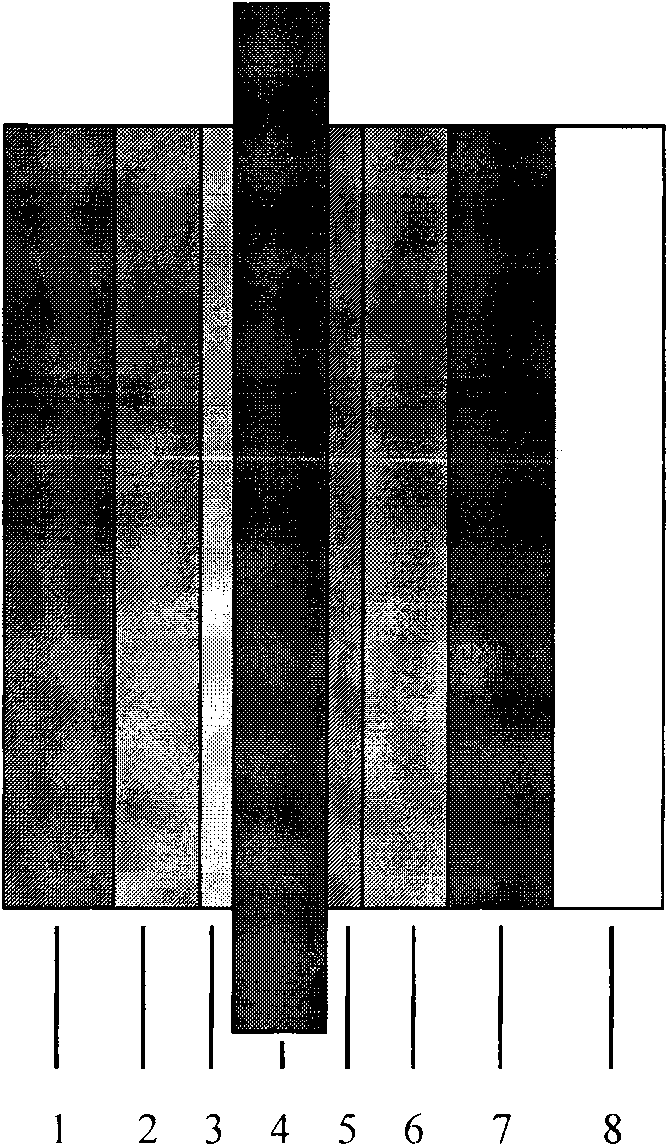

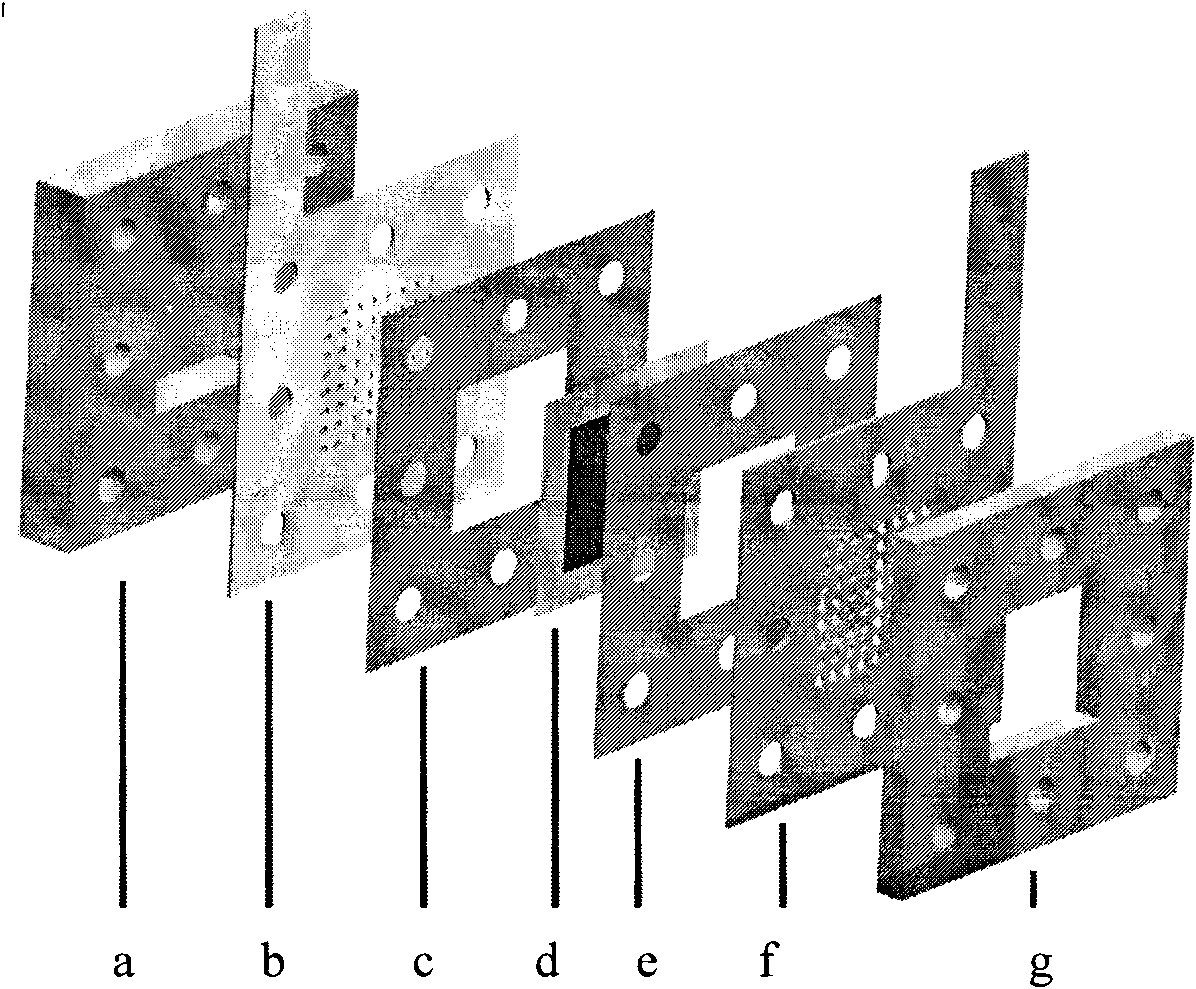

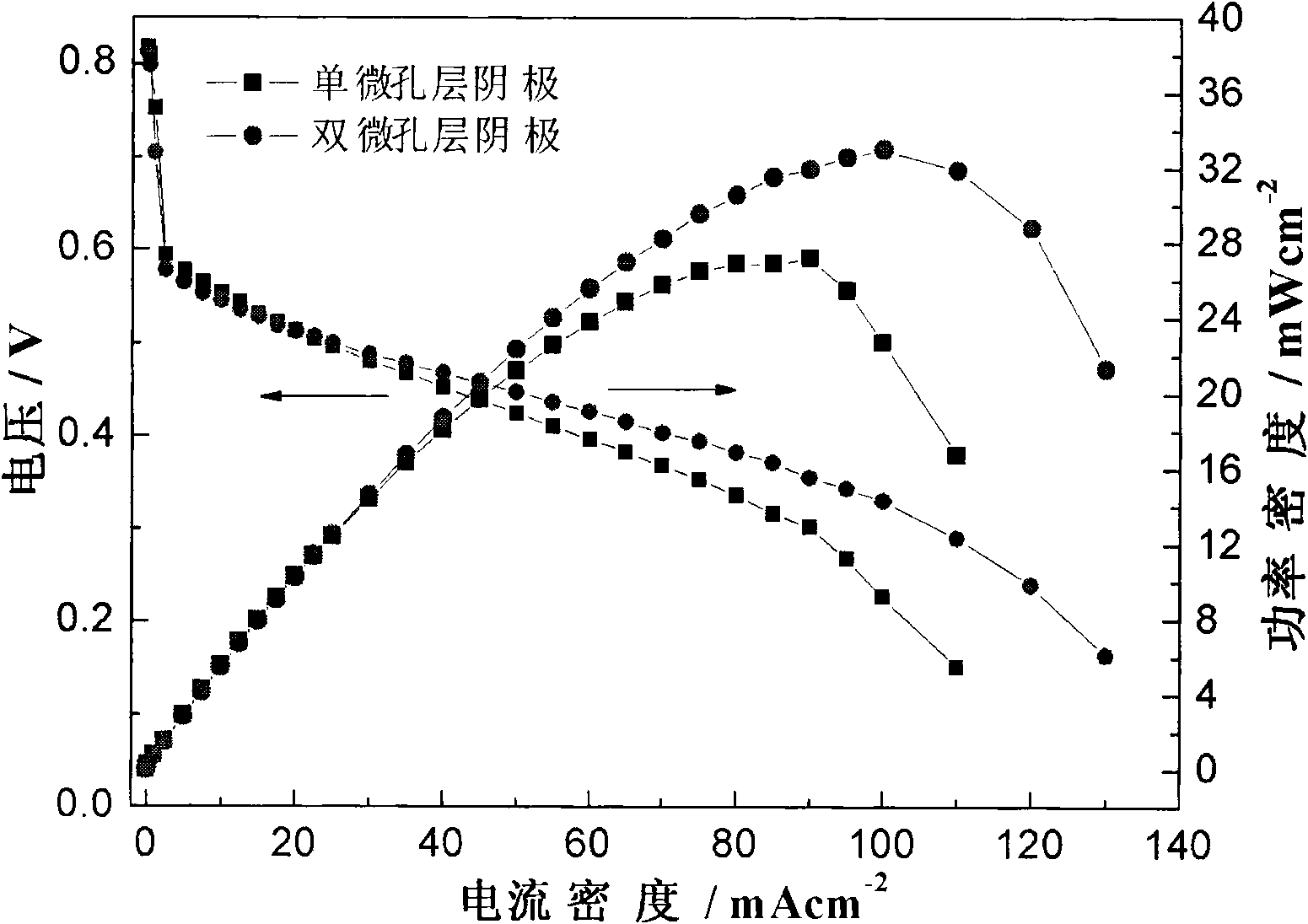

[0024] Embodiment 1 The preparation method of the MEA of the double microporous layer cathode structure of the direct methanol fuel cell

[0025] 1. Weigh 20mg of Vulcan XC-72R and 50mg of 10.0% PTFE emulsion in mass percentage concentration and disperse in 0.3mL of water and isopropanol mixture (the volume ratio of isopropanol and water is 1:1), ultrasonic After dispersing for 6 hours, a uniform carbon slurry (A) can be obtained. Similarly, take 20mg of Vulcan XC-72R and 67mg mass percent concentration and be dispersed in the mixed solution of 0.3mL water and isopropanol (the volume ratio of isopropanol and water is 1: 1), A uniform carbon slurry (B) can be obtained by ultrasonic dispersion for 6 hours. Weigh 20mg of Ketjen Black and 200mg of 10.0% PTFE emulsion in mass percentage concentration and disperse in 0.5mL of water and isopropanol mixture (the volume ratio of isopropanol and water is 1:1), and ultrasonically disperse for 6h. A homogeneous carbon slurry (C) is obta...

Embodiment 2

[0032] Example 2 Influence of the Binder of the Microporous Layer in the Double Microporous Layer Cathode of Direct Methanol Fuel Cell and the Preparation Method of MEA

[0033] 1. Weigh 80mg of Vulcan XC-72R and 200mg of 10.0% PTFE emulsion by mass percent and disperse them in a mixture of 1.2mL water and isopropanol (the volume ratio of isopropanol and water is 1:1), and ultrasonically After dispersing for 6 hours, a uniform carbon slurry (A) can be obtained. Similarly, take 80mg of Vulcan XC-72R and 268mg mass percentage concentration and be dispersed in the mixed solution of 1.2mL water and isopropanol (the volume ratio of isopropanol and water is 1: 1), A uniform carbon slurry (B) can be obtained by ultrasonic dispersion for 6 hours. Weigh 20 mg of Ketjen Black and 85.7 mg of PTFE emulsion with a concentration of 10.0% by mass and disperse them in a mixed solution of 0.4 mL of water and isopropanol (the volume ratio of isopropanol and water is 1:1), and ultrasonically di...

Embodiment 3

[0039] Example 3 Influence of microporous layer carbon material in double microporous layer cathode of direct methanol fuel cell and preparation method of MEA

[0040]1. Weigh 80mg of Vulcan XC-72R and 200mg of 10.0% PTFE emulsion by mass percent and disperse them in a mixture of 1.2mL water and isopropanol (the volume ratio of isopropanol and water is 1:1), and ultrasonically After dispersing for 6 hours, a uniform carbon slurry (A) can be obtained. Similarly, take 80mg of Vulcan XC-72R and 268mg mass percentage concentration and be dispersed in the mixed solution of 1.2mL water and isopropanol (the volume ratio of isopropanol and water is 1: 1), A uniform carbon slurry (B) can be obtained by ultrasonic dispersion for 6 hours. Weigh 20mg of Ketjen Black and 200mg of 10.0% PTFE emulsion in mass percentage concentration and disperse in 0.5mL of water and isopropanol mixture (the volume ratio of isopropanol and water is 1:1), and ultrasonically disperse for 6h. A homogeneous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com