Preparation method of integral GaN-based film

A technology for integrity and epitaxial thin films, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as edge damage of unit GaN-based epitaxial thin films, achieve the effects of reducing cracking, ensuring integrity, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] A method for preparing a complete GaN-based epitaxial film, the preparation steps are as follows:

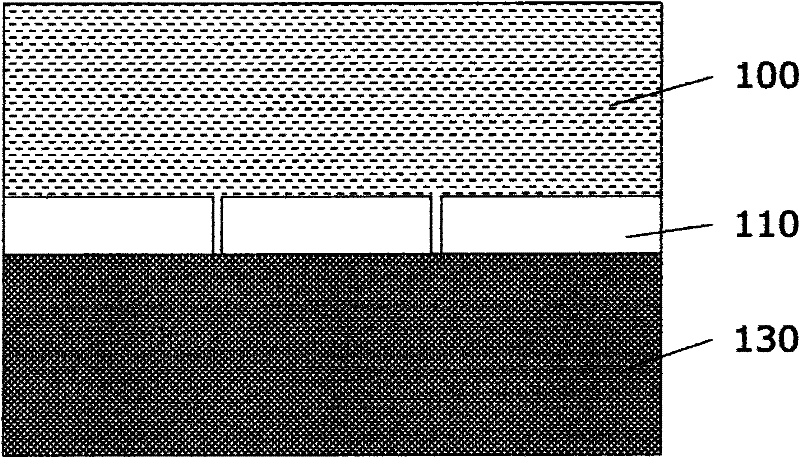

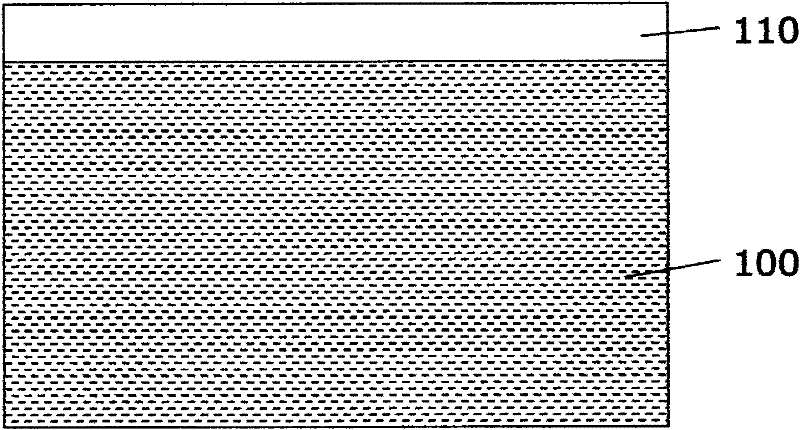

[0024] like Figure 2a As shown, an N-type GaN-based semiconductor layer, an active layer, and a P-type GaN-based semiconductor layer are sequentially epitaxially grown on a sapphire substrate 100 by metal-organic chemical vapor deposition (MOCVD) to form a GaN-based LED epitaxial layer 110;

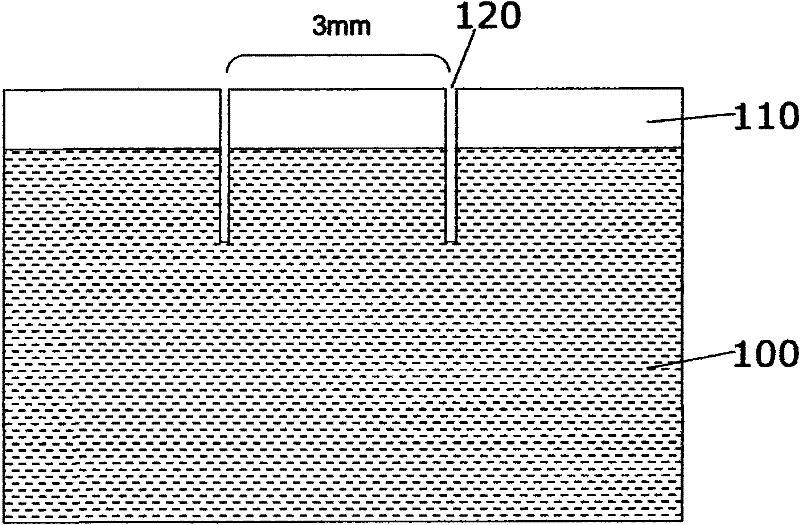

[0025] like Figure 2b As shown, a laser scriber (wavelength 355nm) is used to scribe from the GaN-based epitaxial layer 110 and extend to the sapphire substrate 100. The scribing is carried out in an orthogonal (X-Y axis) manner with a period of 3mm×3mm, and the set The laser stripping spot size is similar, and the depth of the laser scribing is 30 microns, that is, the preset channel 120 is formed, and its plan view is as follows image 3 shown;

[0026...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com