Solar selective absorbing coating and preparation method thereof

An absorbing coating and selective technology, applied in solar thermal power generation, coating, solar thermal devices, etc., can solve the problem of high cost and achieve the effect of stable coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

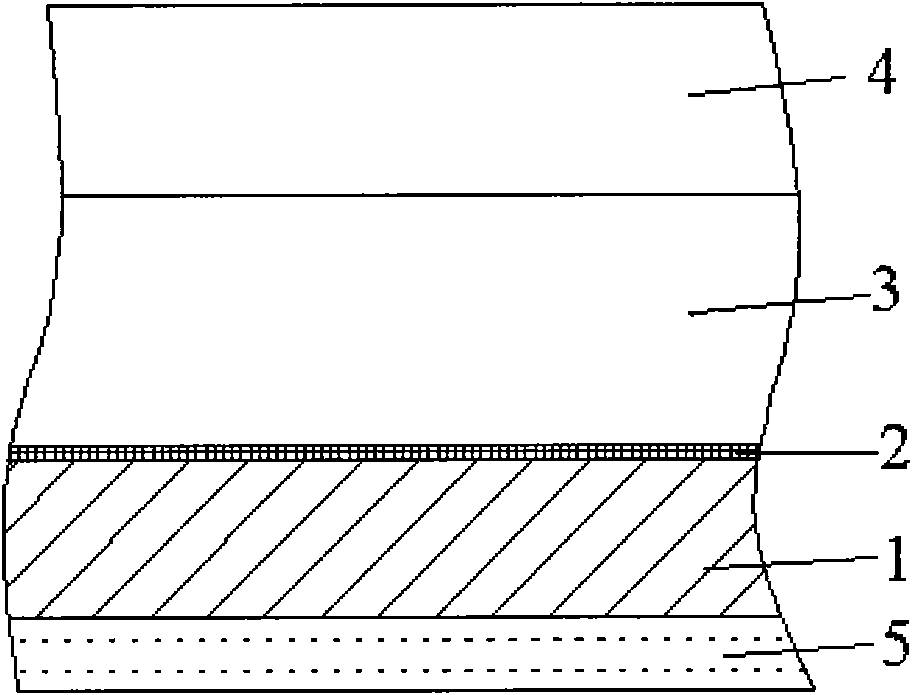

[0032] Cu / Al / SS deposition on glass tubes 1 -O x1 -AlN y1 o z1 / SS 2 -O x2 -AlN y2 o z2 / AlN i o j Selective Absorbent Coating:

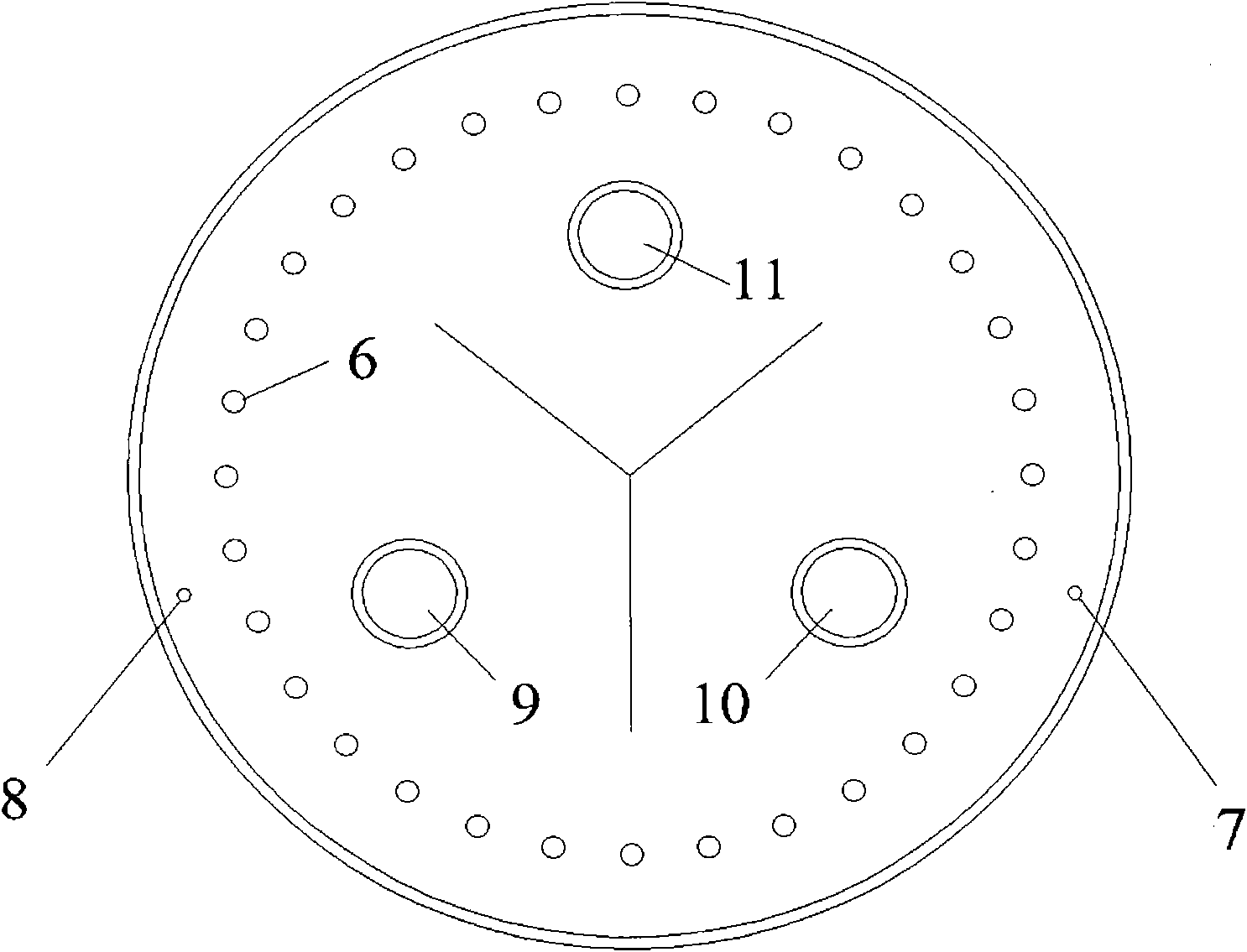

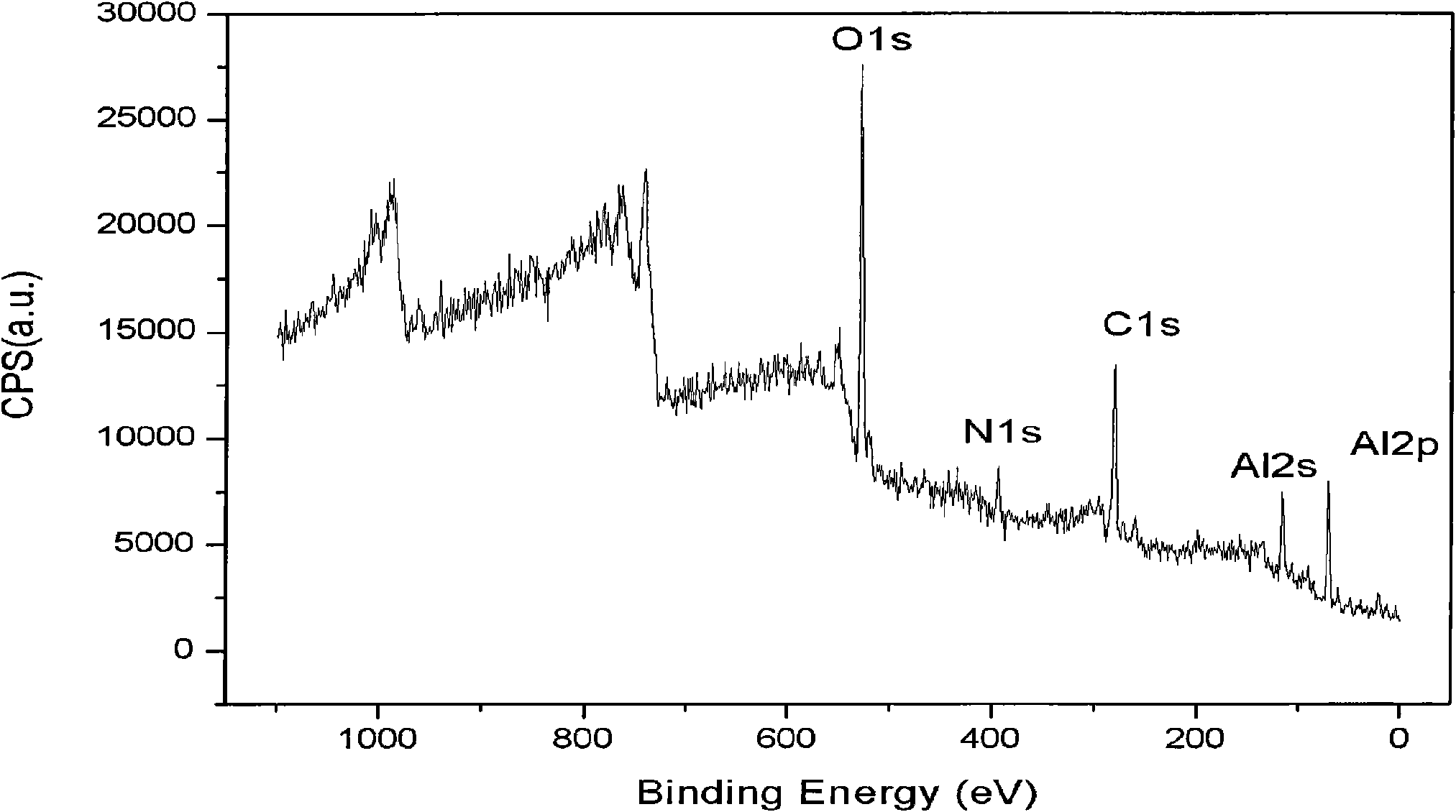

[0033] exist figure 2 In the vacuum chamber of the cylindrical magnetron sputtering coating machine shown, the workpiece 6 is a glass tube, which can rotate and revolve. When the vacuum degree reaches 10 -3 Pa, fill pure argon gas from the argon gas inlet pipe 7, work at 0.20 Pa, Cu target 11 is DC sputtering to deposit Cu metal layer, the power is 16KW, the time is 6 minutes, and the Dektak 6M step meter of American Veeco company is used for testing. Its thickness is 150nm; then direct current sputtering Al target, deposit Al film as a diffusion barrier layer, power 12KW, time 30 seconds, use Dektak 6M step meter to measure the thickness of Al film is 22nm; then adjust the flow of argon gas to make the working pressure 0.40 Pa, according to the molar ratio of nitrogen and oxygen is approximately 97:3, N 2 The flow is 129SCCM, O 2The f...

Embodiment 2

[0037] Deposit Cu / Al / SS on polished stainless steel sheet as substrate 1 -O x1 -AlN y1 o z1 / SS 2 -O x2 -AlN y2 o z2 / SS 3 -O x3 -AlN y3 o z3 / SS 4 -O x4 -AlN y4 o z4 / AlN i o j Selective Absorbent Coating:

[0038] like figure 2 In the vacuum chamber of the cylindrical magnetron sputtering coating machine shown, the substrate stainless steel sheet is fixed on the workpiece 6, when the vacuum degree reaches 10 -3 Pa, fill the pure argon gas from the argon gas inlet pipe 7, the working pressure is 0.20Pa, the Cu target 11 is DC sputtering to deposit the Cu metal layer, the time is 6 minutes, the power is 16KW, and the thickness is 150nm as measured by the Dektak 6M step meter; Then Al target is DC sputtered to deposit Al film as a diffusion barrier layer, the power is 12KW, the time is 30 seconds, and the thickness is 22nm measured by Dektak 6M step meter; then the flow rate of argon gas is adjusted to keep the working pressure at 0.40Pa, which is approximate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com