Preparation method of texture controllable fine grain metal material based on large strain deformation and recrystallization

A metal material and large strain technology, which is applied in the field of preparation of texture-controllable fine-grained metal materials, can solve the problems of difficulty in obtaining fine-grained metal materials with texture-controllable grains, etc., and achieves the effect of increasing hardness and increasing yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: The billet is made of annealed commercially pure aluminum, wherein the rolling strain is 1.75 (download 80%), and the ECAP strain is 0.8. Heat treatment is carried out at 200° C., heat preservation for 1 hour, and air cooling. The prepared industrial pure aluminum has a crystal grain size of 1-2 microns and a sub-grain size of about 50 nanometers, and its yield strength is 60% higher than that of the original blank, and its hardness is 50% higher than that of the original blank.

Embodiment 2

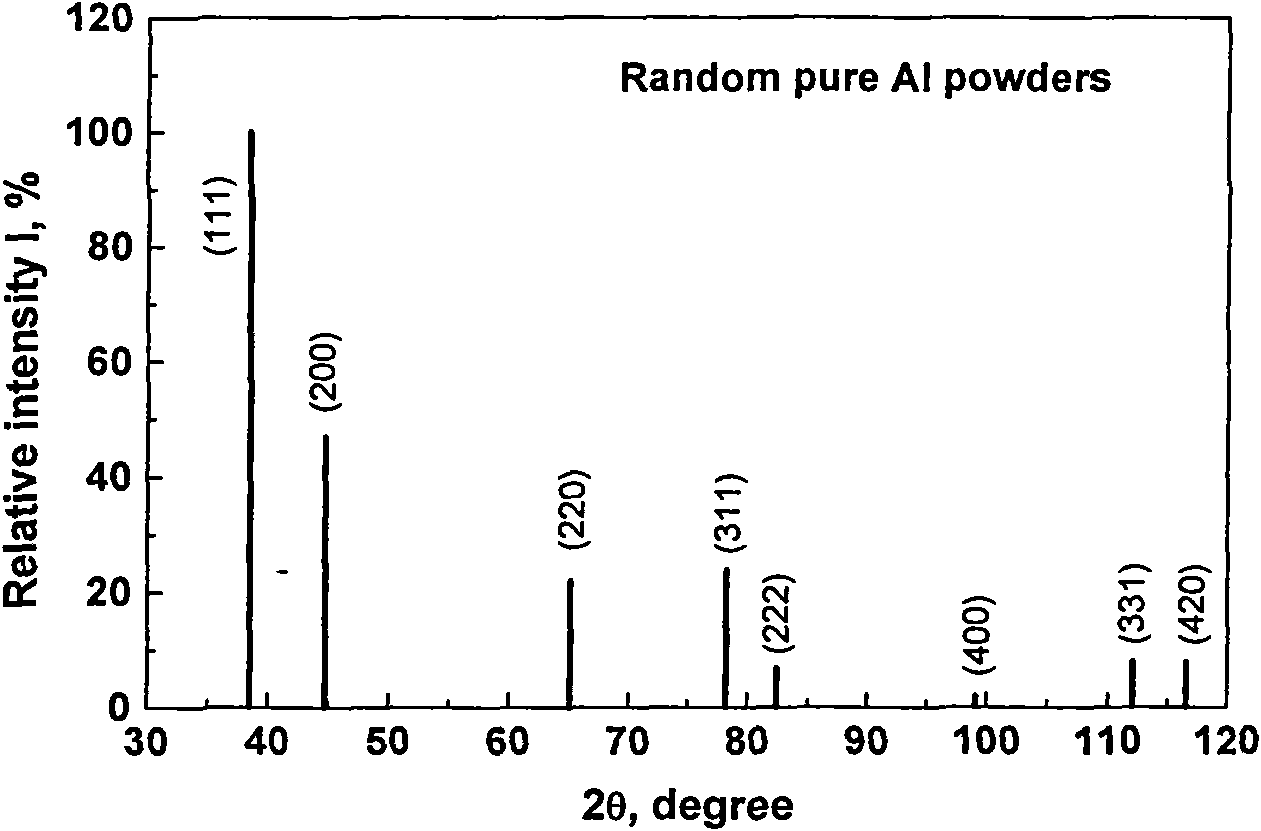

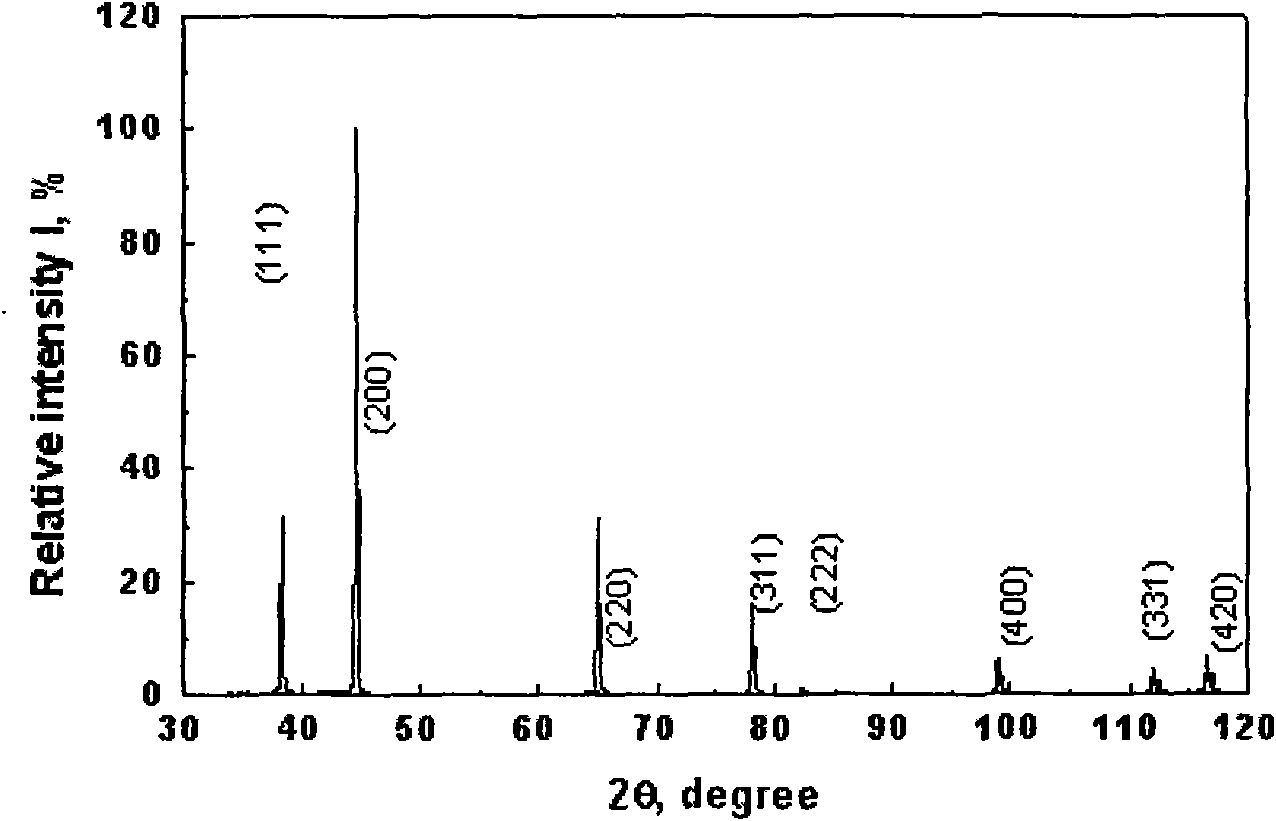

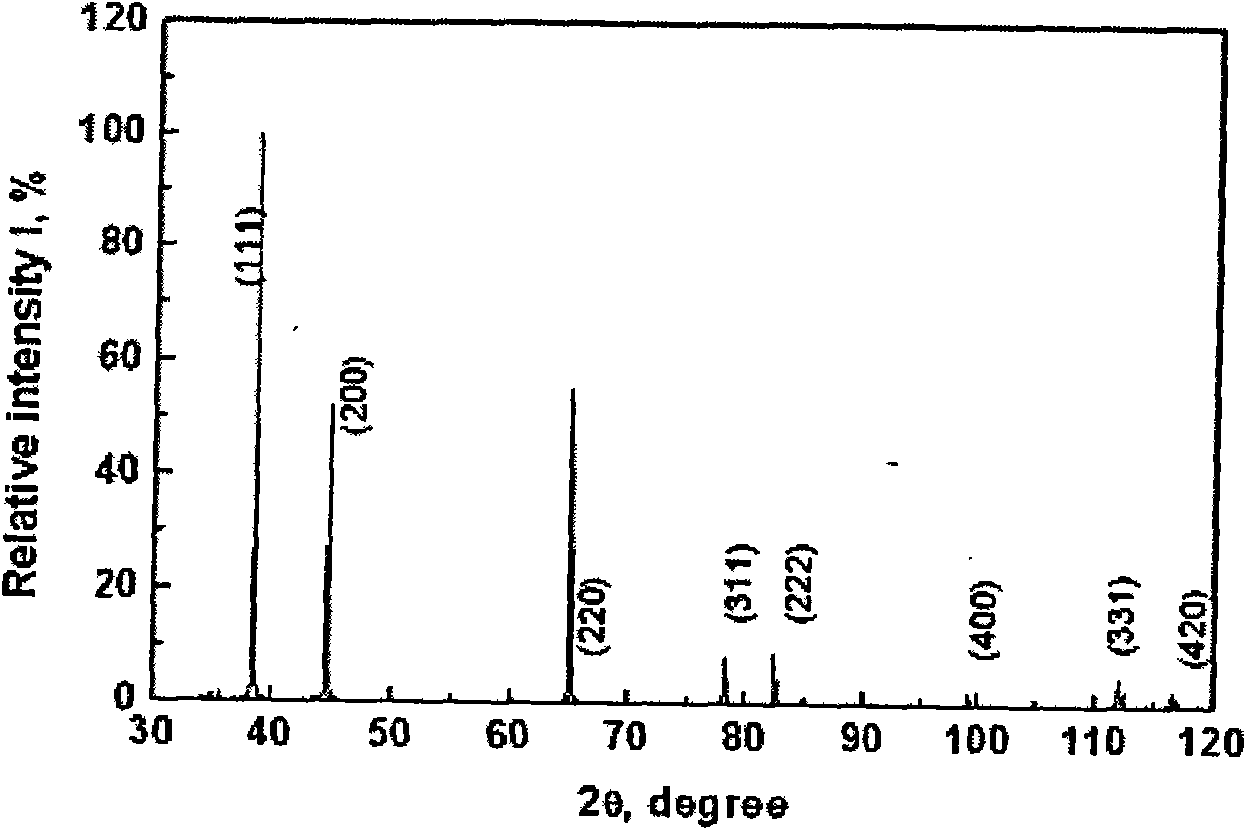

[0022] Example 2: The billet is made of annealed industrial pure aluminum, wherein the rolling strain is 0.4 (download 50%), the ECAP strain is 0.8, heat treatment is carried out at 500° C., heat preservation for 1 hour, and air cooling. The prepared industrial pure aluminum has a good texture orientation, and its XRD spectrum ( image 3 ) is very close to the standard XRD spectrum of pure aluminum ( figure 1 ),From figure 2 As can be seen, the XRD and standard XRD spectra ( figure 1 ) is very different.

Embodiment 3

[0023] Example 3: The blank is made of annealed 5052 aluminum alloy, the rolling strain is 0.4 (download 50%), the ECAP strain is 0.8, heat treatment is carried out at 500° C., heat preservation for 1.5 h, and air cooling. The prepared 5052 aluminum alloy has a good texture orientation, and its XRD spectrum is very close to that of ideal industrial pure aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com