Method for nano reconstruction of surface texture of metal roller

A roll and metal technology, which is applied in the field of nano-reconstruction of the surface structure of metal rolls, can solve problems affecting performance, surface layer peeling, surface damage, etc., achieve optimization effects, stabilize nano-grains, and increase thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

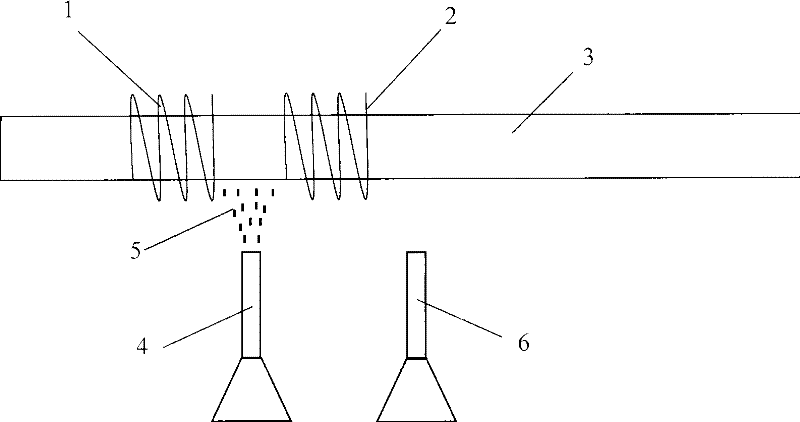

Method used

Image

Examples

Embodiment 1

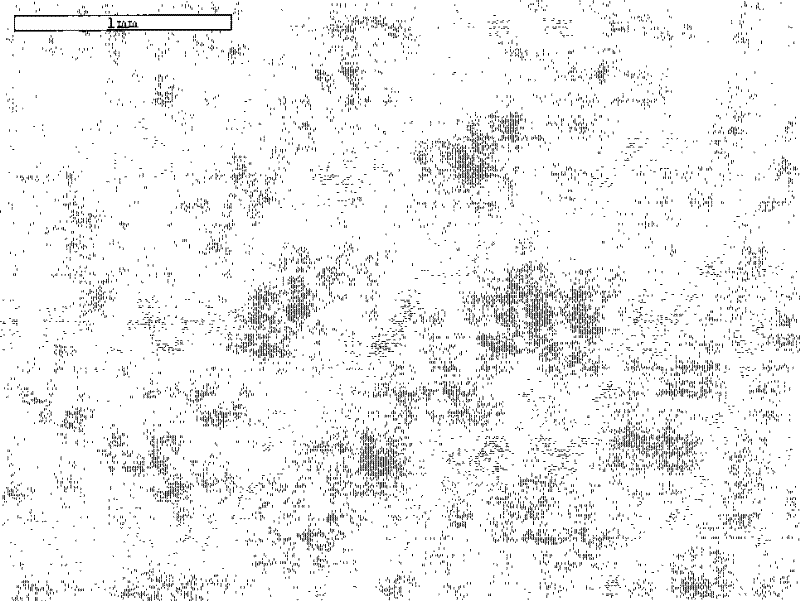

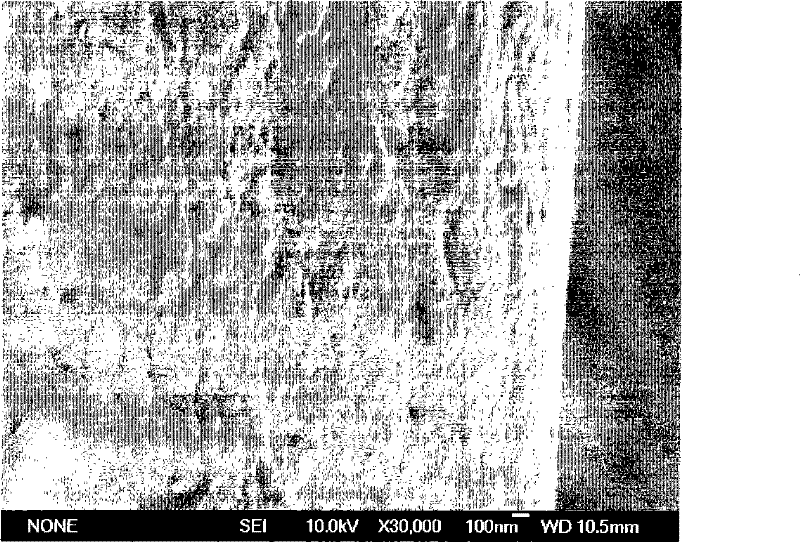

[0043] The surface of the pickling and straightening roller is nano-strengthened, the original roller material is 100Cr6 steel, the surface is quenched, the Vickers hardness of the hardened layer is 480HV, the surface is polished, and the roughness is Ra0.45. Treatment process: The relative moving speed of the induction coil and the roller is 2mm / s, the heating frequency of the induction coil is 300kHZ, the surface temperature of the roller after heating is 558°C, and the bombardment uses α-Al with an average particle size of 40μm 2 o 3 For particles, the working gas preheating temperature is 350°C, the working gas pressure is 2MPa, the spray distance is 30mm, and the particle bombardment density is 2000-2600 / mm 2 . The surface morphology of the roller after surface nano-treatment is as follows: figure 2 shown, according to figure 2 It can be seen that the surface is a matte rough surface, and the surface roughness is Ra0.8; the surface layer is a gradient transition stru...

Embodiment 2

[0045] The surface of the pickling and straightening roller is nano-strengthened, the original roller material is 100Cr6 steel, the surface is quenched, the Vickers hardness of the hardened layer is 550HV, the surface is polished, and the roughness is Ra0.3. Treatment process: The relative moving speed of the induction coil and the roller is 1.5mm / s, the heating frequency of the induction coil is 300kHZ, the surface temperature of the roller after heating is 688°C, and the bombardment uses α-Al with an average particle size of 30μm 2 o 3 For particles, the working gas preheating temperature is 100°C, the working gas pressure is 1.5MPa, the spray distance is 35mm, and the particle bombardment density is 1300-1500 / mm 2 . After treatment, the surface roughness of the tensioning and leveling roller is Ra0.7, and the hardness of the surface layer is 40% higher than that of the matrix.

Embodiment 3

[0047] The surface of the support roll of the pickling and leveling machine is nano-strengthened. The original roll material is 50CrMo4V steel, the Vickers hardness of the hardened layer is 500HV, and the surface roughness is Ra0.35. Treatment process: The relative moving speed of the induction coil and the roller is 1.8mm / s, the heating frequency of the induction coil is 300kHZ, the surface temperature of the roller after heating is 620°C, and the bombardment uses α-Al with an average particle size of 35μm 2 o 3 For particles, the working gas preheating temperature is 200°C, the working gas pressure is 2MPa, the spray distance is 40mm, and the particle bombardment density is 1300-1500 / mm 2 . After treatment, the surface roughness of the tensioning and leveling roller is Ra0.7, and the hardness of the surface layer is more than 50% higher than that of the matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com