Preparation method of fucosan

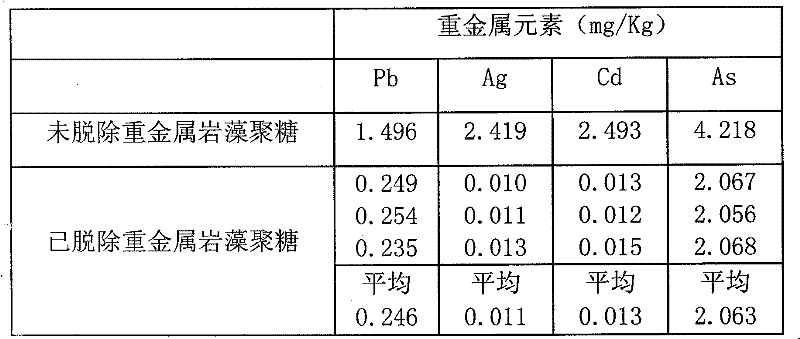

A fucoidan and concentration technology, applied in the field of fucoidan preparation, can solve the problems of high heavy metal content, no consideration of heavy metal removal, affecting product quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The present invention is a preparation method of fucoidan, comprising the following steps:

[0016] (1) Get 100kg of dried kelp, remove sand and sundries, dry, pulverize, and sieve 80 meshes to make kelp dry powder.

[0017] (2) Take 50Kg of the above-mentioned dried kelp powder, add 1000Kg of deionized water, and stir evenly. After incubating at 80°C for 3 hours, centrifugation was carried out with a tubular continuous centrifuge (10,000 revolutions per minute, 10 minutes) to obtain about 300 Kg of supernatant.

[0018] (3) Concentrated hydrochloric acid (HCl) was made into a concentration of 4 mol / L, and added to the above-mentioned supernatant in proportion to make the HCl concentration reach 0.1 mol / L. After standing for 15 minutes, it was centrifuged with a tubular continuous centrifuge, and the precipitate was mainly alginic acid impurities. About 250Kg of supernatant was obtained.

[0019] (4) The solid sodium hydroxide (NaOH) was prepared into a 6N concentrat...

Embodiment 2

[0028] The present invention is a preparation method of fucoidan, comprising the following steps:

[0029] (1) Get 100kg of dried kelp, remove sand and sundries, dry, pulverize, and sieve 80 meshes to make kelp dry powder.

[0030] (2) Take 50Kg of the above-mentioned dried kelp powder, add 900Kg of deionized water, and stir evenly. After incubating at 75°C for 3 hours, centrifugation was carried out with a tubular continuous centrifuge (600 revolutions per minute, 12 minutes) to obtain about 300Kg of supernatant.

[0031] (3) Concentrated hydrochloric acid (HCl) was made into a concentration of 4 mol / L, and added to the above-mentioned supernatant in proportion to make the HCl concentration reach 0.1 mol / L. After standing for 18 minutes, it was centrifuged with a tubular continuous centrifuge, and the precipitate was mainly alginic acid impurities. About 250Kg of supernatant was obtained.

[0032] (4) Solid sodium hydroxide (NaOH) was prepared into a 6N concentration solut...

Embodiment 3

[0037] The present invention is a preparation method of fucoidan, comprising the following steps:

[0038] (1) Get 100kg of dried kelp, remove sand and sundries, dry, pulverize, and sieve 80 meshes to make kelp dry powder.

[0039] (2) Take 50Kg of the above-mentioned dried kelp powder, add 950Kg of deionized water, and stir evenly. After incubating at 77° C. for 3.5 hours, centrifugation was carried out in a tubular continuous centrifuge (800 revolutions per minute, 15 minutes) to obtain about 300 Kg of supernatant.

[0040] (3) Concentrated hydrochloric acid (HCl) was made into a concentration of 4 mol / L, and added to the above-mentioned supernatant in proportion to make the HCl concentration reach 0.1 mol / L. After standing for 20 minutes, it was centrifuged with a tubular continuous centrifuge, and the precipitate was mainly alginic acid impurities. About 250Kg of supernatant was obtained.

[0041] (4) The solid sodium hydroxide (NaOH) is made into a 6N concentration sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com