Low rudder supporting axle processed tooling

A technology for supporting shafts and tooling, which is used in supports, metal processing equipment, metal processing machinery parts, etc., and can solve problems such as high technical requirements, inability to guarantee product quality stability, and difficulty in guaranteeing shape and position tolerances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

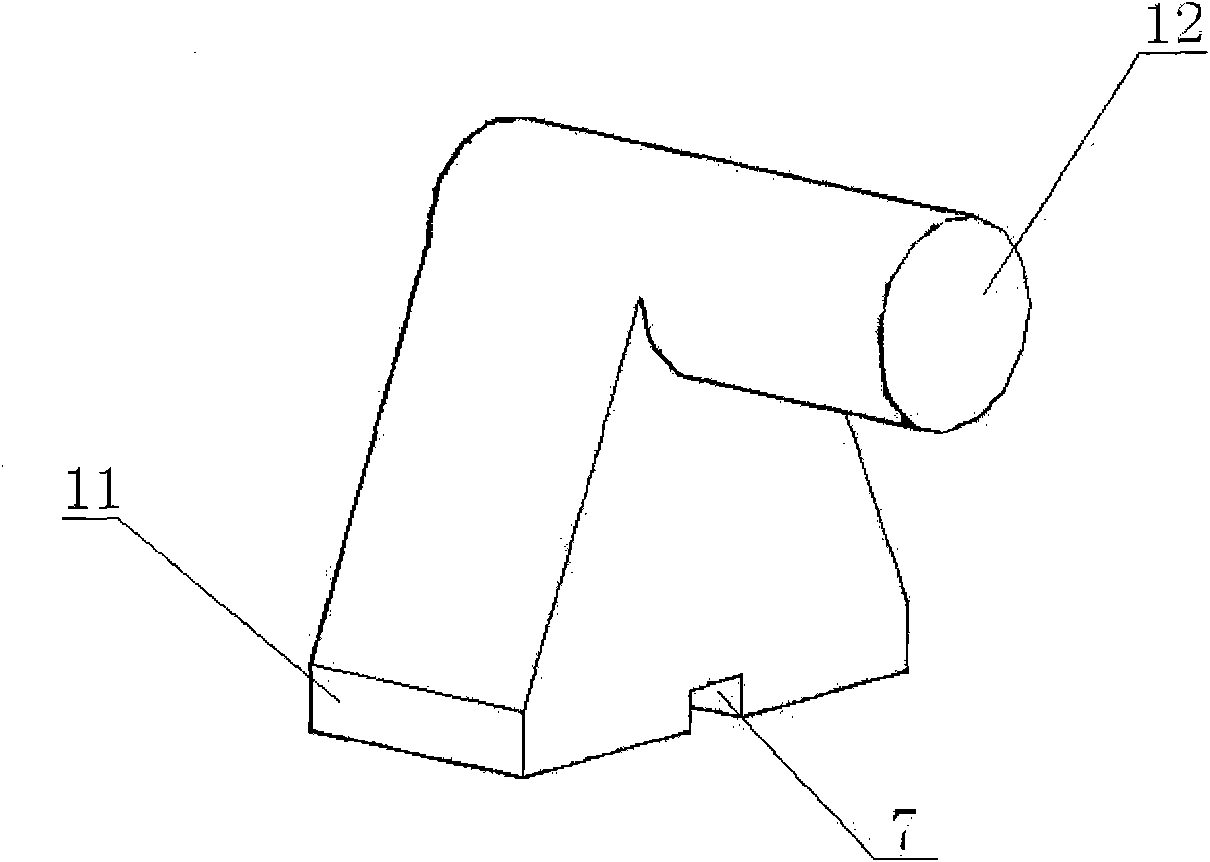

[0009] Such as figure 1 As shown, the lower rudder support shaft is integrally formed by a support base 11 and a cylindrical shaft 12, the cylindrical shaft 12 is horizontally arranged on the support base 11, and the bottom surface of the support base 11 is provided with a right angle groove 7 parallel to the axis of the cylindrical shaft 12.

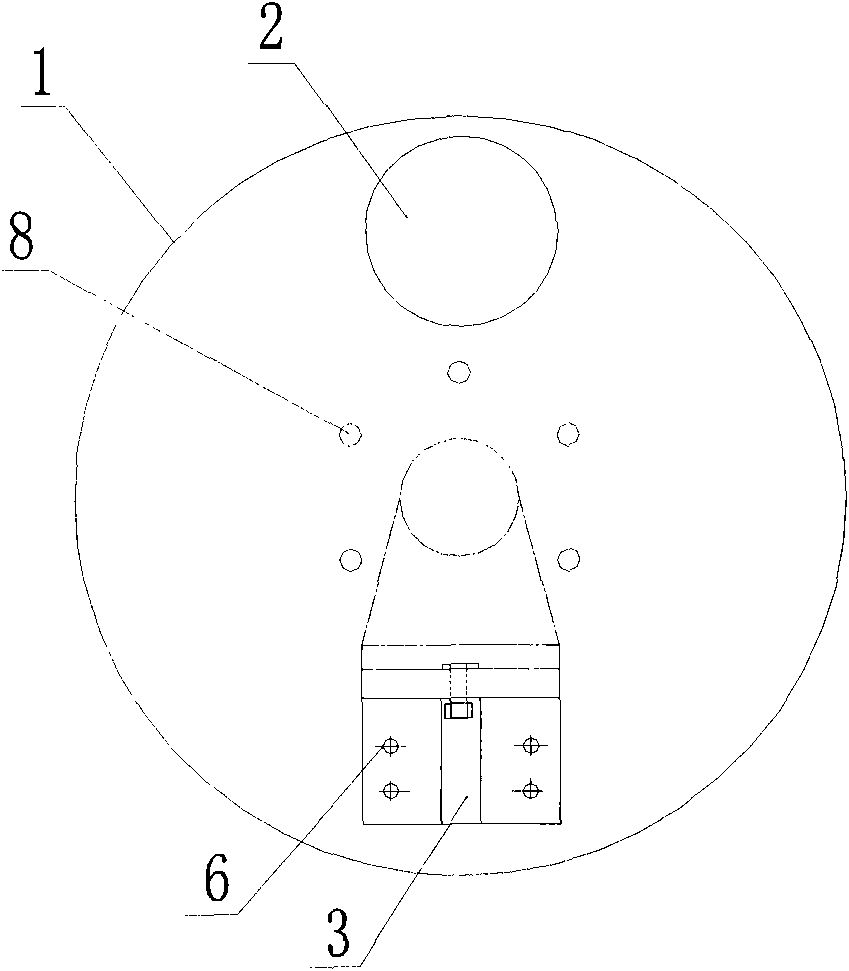

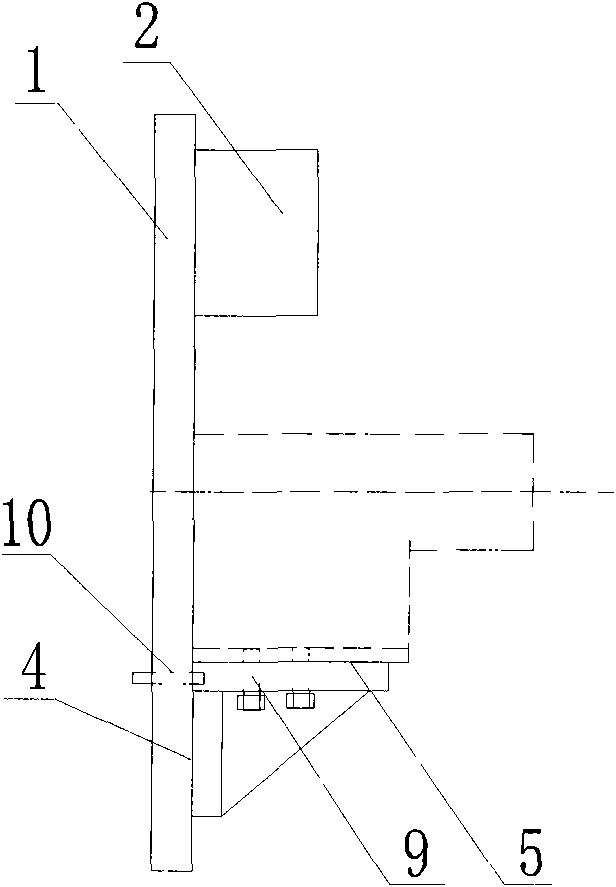

[0010] Such as figure 2 , 3 As shown, the present invention relates to a processing tool for the lower rudder support shaft, which includes a faceplate 1, a hole 8, an angle iron 3, and a counterweight 2.

[0011] The above-mentioned faceplate 1 is provided with a hole 8 for fixing the faceplate on the main shaft of the lathe, and an angle iron 3 is arranged at the bottom. The angle iron 3 has two mutually perpendicular right-angled surfaces 4, 5, the right-angled surface 4 is fixed on the faceplate 1 by bolts 6, and its central symmetry line passes through the center of the faceplate 1, and the right-angled surface 4 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com