High-efficiency environmental-friendly coal-saving sulphur-fixing antismoke agent and production technology thereof

A technology of smoke suppressant and sulfur-fixing agent, which is used in solid fuel, petroleum industry, and dispersed particle separation, etc., can solve the problems of low thermal efficiency of boilers, difficult to ignite, and insufficient combustion, so as to prolong the open fire time and improve the coal briquette. Quality, the effect of solving insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

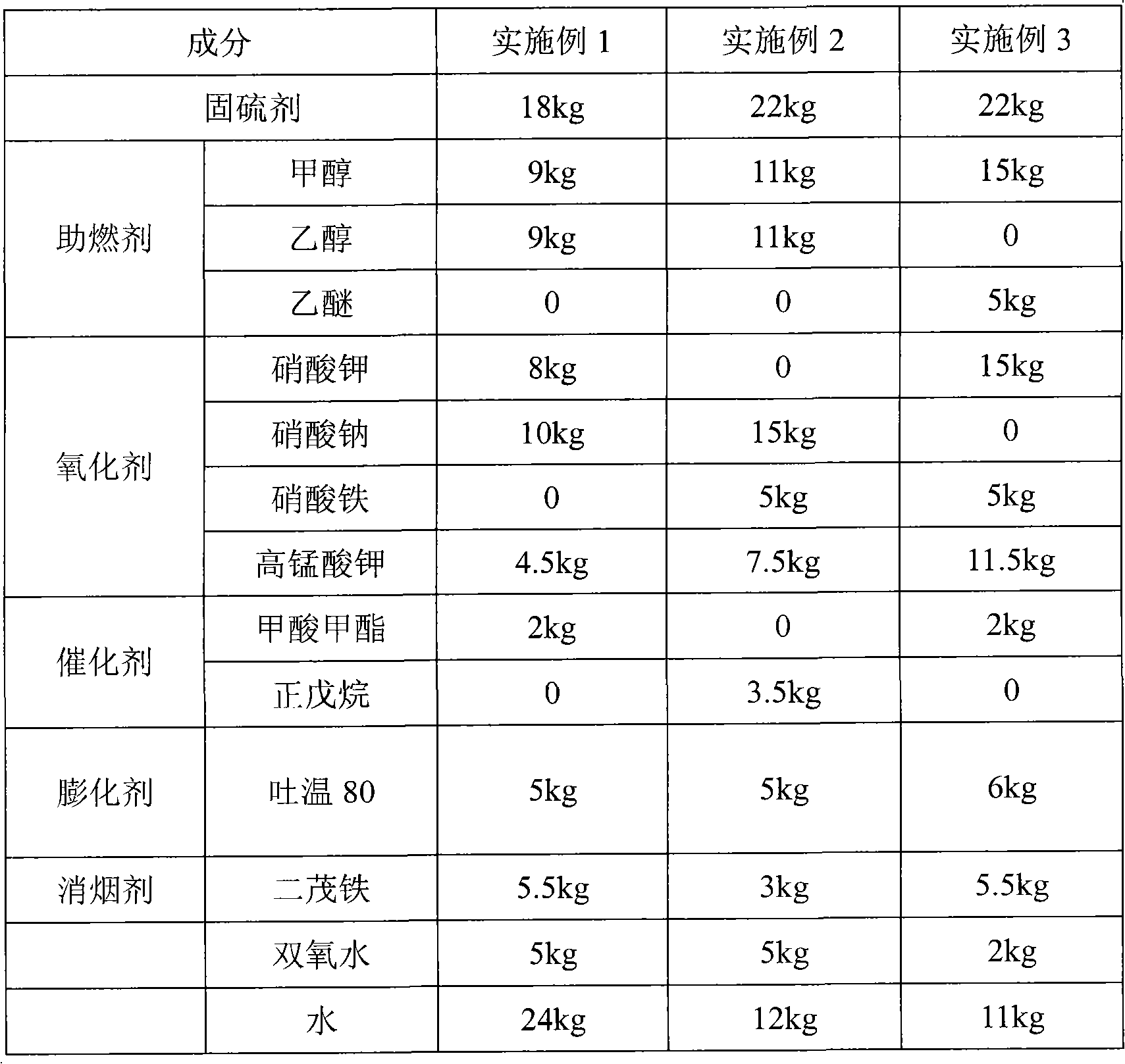

Embodiment 1~3

[0053] Embodiment 1~3 adopts following production technology to make:

[0054] A. Add appropriate amount of water to the sulfur-fixing agent to prepare a sulfur-fixing agent solution;

[0055] B. Add appropriate amount of water to the combustion aid and oxidant, fully dissolve, heat to 60°C, and react for two hours to make a mixed solution of combustion aid and oxidant;

[0056] C. Add an appropriate amount of water to the catalyst, heat it to 60°C, and react for one hour to make a catalyst solution;

[0057]D. Add smoke suppressant to the mixed solution of combustion accelerant and oxidizing agent obtained in step B, fully stir and mix evenly;

[0058] E. The catalyst solution obtained in step C is added to the product obtained in step D, fully stirred, and mixed uniformly;

[0059] F. Add the sulfur-fixing agent solution obtained in step A into the product obtained in step E, fully stir, and mix uniformly;

[0060] G. Add the bulking agent to the product obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com