Oxygen storage/release material and exhaust gas purifying catalyst comprising the same

A technology for releasing materials and exhaust gas purification, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, oxygen/ozone/oxide/hydroxide, etc. Purification performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The present invention will be described in detail below based on examples, but the present invention is not limited thereto.

[0036] In the following examples, the catalyst for exhaust gas purification is prepared by the following operation: Pd as a catalyst noble metal is supported on Pr 2 o 2 SO 4 On the oxygen storage / release material obtained by replacing a part of Pr with Ce, its oxygen release ability was examined.

Embodiment 1

[0041] Obtain exhaust gas purification catalyst Pd / (Pr in the same manner as Comparative Example 1 0.8 Ce 0.2 ) 2 o 2 SO 4 , the difference is that cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) instead of a part of raw material praseodymium nitrate hexahydrate (Pr(NO 3 ) 3 ·6H 2 O), so that the charging ratio becomes Pr: Ce=0.8: 0.2 (mol).

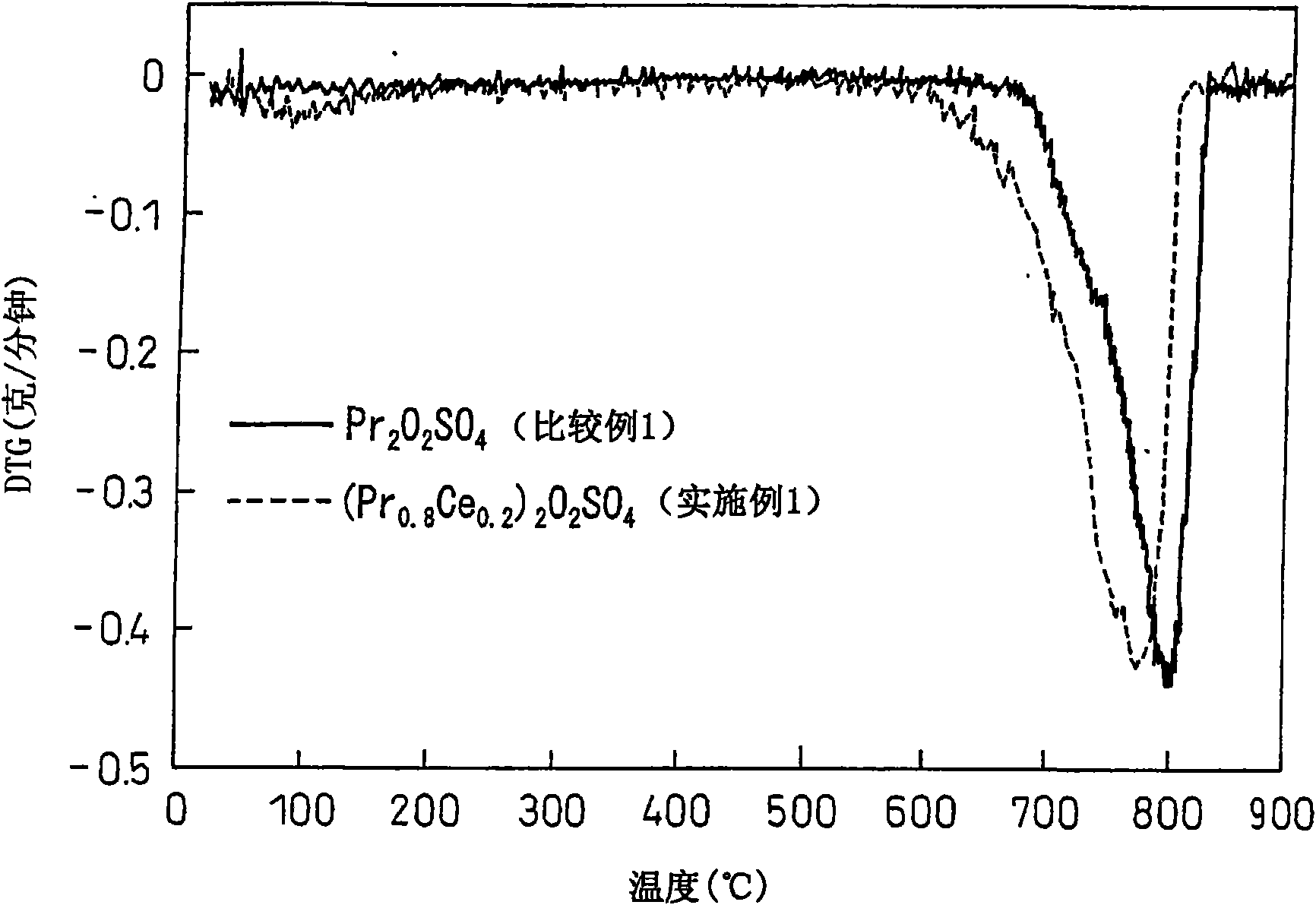

[0042] The catalysts for purification of exhaust gas of Comparative Example 1 and Example 1 prepared above were evaluated for oxygen releasing ability by derivative thermogravimetric analysis (DTG). In other words, each catalyst was heated to 900 °C at a heating rate of 10 °C / min while supplying it with a test gas of 5% H 2 / He, measuring the change in mass of each catalyst accompanying the release of oxygen from the oxygen storage / release material during temperature rise. The results obtained are shown in figure 1 .

[0043] figure 1 A graph showing the measurement results of derivative thermogravimetric analysis (DTG) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com