Electromagnet driven gyroscope based on nanometer film quantum tunneling effect

A quantum tunneling and electromagnetic drive technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, piezoelectric/electrostrictive/magnetostrictive devices, etc., to achieve simple structure , low power consumption requirements, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

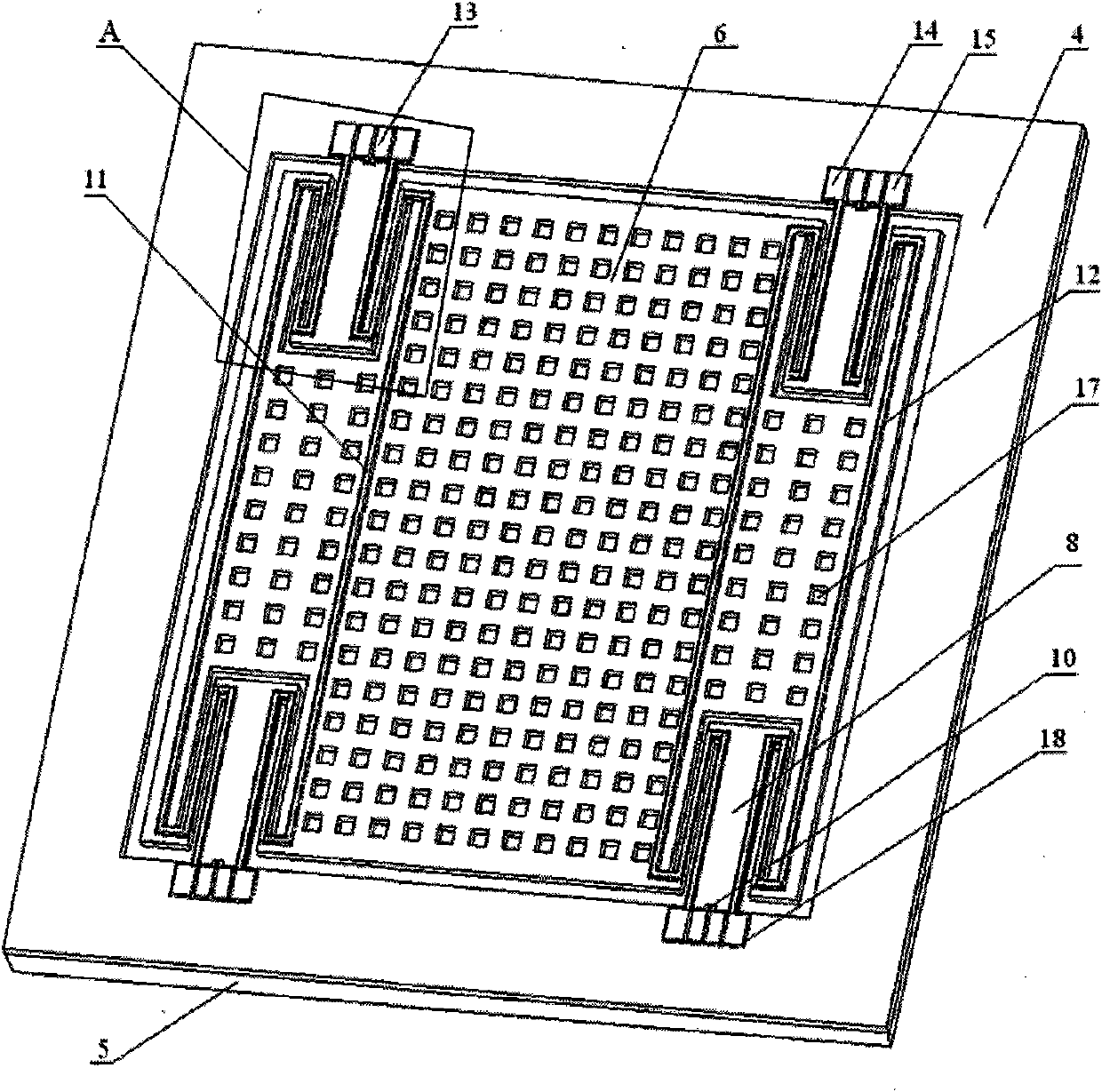

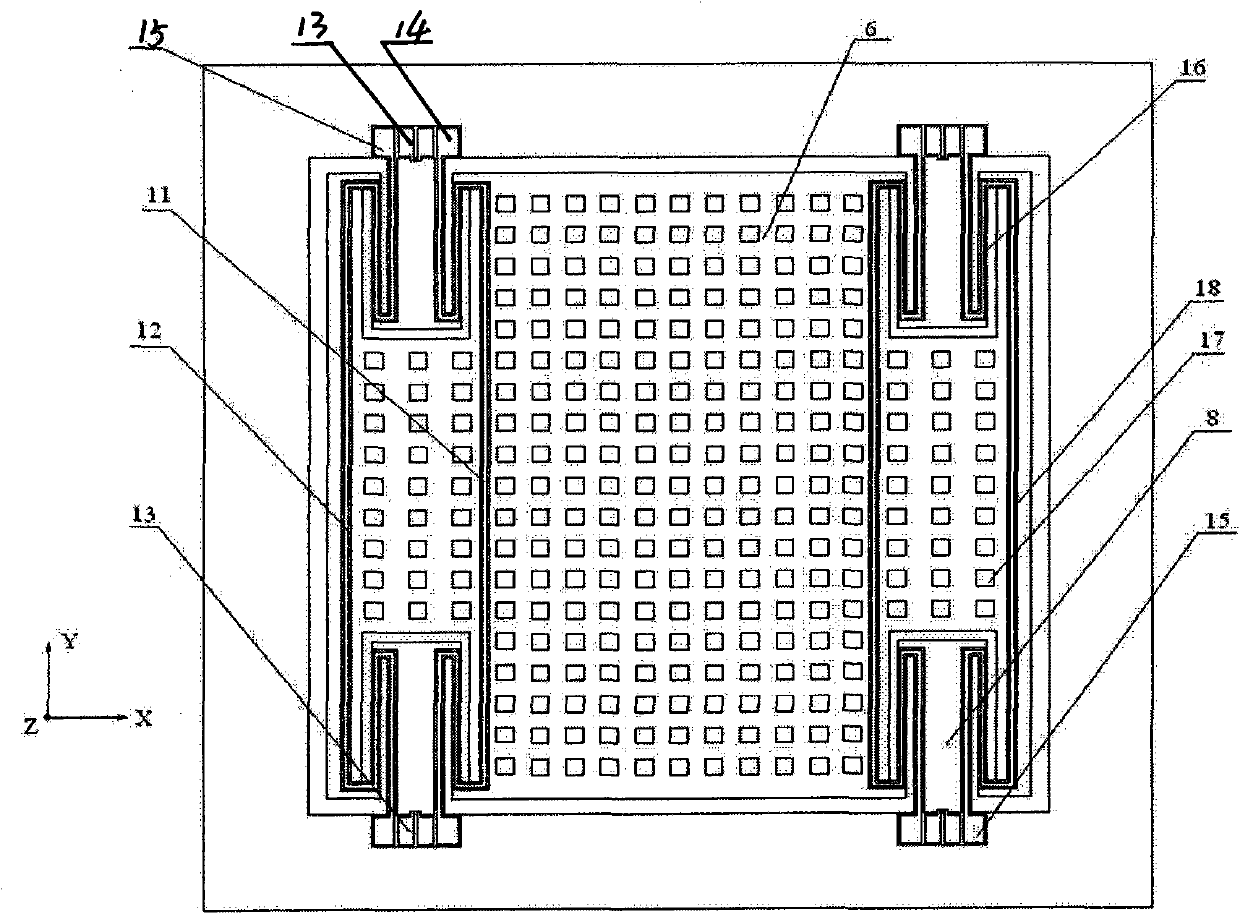

[0019] The electromagnetically driven gyroscope based on the nano-film quantum tunneling effect includes a carrier plate 1, a gyro tube core 2 welded and fixed on the central area of the carrier plate 1, and a permanent magnet 3 is embedded in the central area of the carrier plate 1, and the gyro tube core 2 A gyro-sensitive mechanism is packaged; the gyro-sensitive mechanism includes a support frame 4, a glass substrate 5 bonded and fixed to the lower surface of the support frame 4, a mass block 6 erected in the center of the support frame 4 through a composite beam, and the mass The four-quadrant area divided by the X-axis centerline and the Y-axis centerline on the block 6 is provided with beam placement grooves 7 for setting composite beams, and the beam placement grooves 7 in adjacent quadrants on the mass block 6 are The dividing line between adjacent quadrants - the X-axis centerline or the Y-axis centerline of the quality block 6 is arranged symmetrically; the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com