Tension spring type steel plate locating device for automobile steel plate drawing mould

A technology for drawing dies and automobile steel plates, applied in positioning devices, feeding devices, storage devices, etc., can solve the problems of surface damage, sheet material movement, unstable positioning, etc., to ensure product quality and reliable positioning , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Examples:

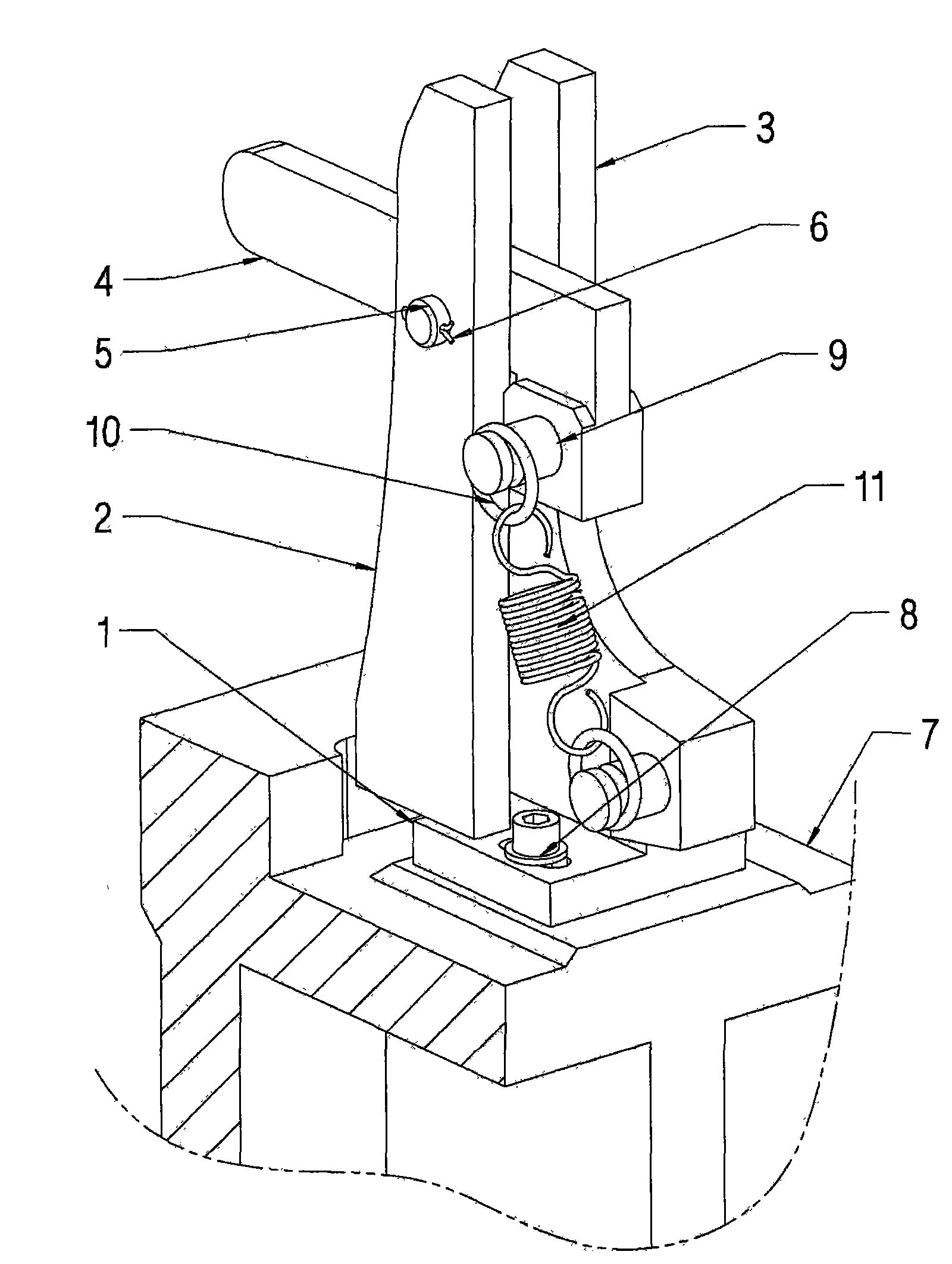

[0012] A tension spring type steel plate positioning device for automobile steel plate drawing dies, consisting of a base 1, two positioning plates 3, a support rod 4, a pin shaft 5, a cotter pin 6 and a tension spring 11; Bolt holes fixed with the mold 7 are provided; two positioning plates 3 are arranged in parallel and are respectively fixed with the base 1, and each of the two positioning plates 3 is provided with a pin hole, and the guide surface 2 of the positioning plate is provided with 30 ° slope and is an arc surface, the positioning plate 3 is provided with an extension spring pin 9; the supporting rod 4 is located in the middle of the two positioning plates 3, and the supporting rod 4 is provided with a pin hole, which passes through the two positioning plates 3 and the pin shaft 5 of the pin hole on the support rod 4 are connected with two positioning plates, the support rod 4 rotates around the pin shaft 5, one end of the pin shaft 5 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com