Automatic dedusting filtering device

A filter device and automatic dust removal technology, which is applied in the direction of filtration separation, dispersed particle filtration, and dispersed particle separation, etc., can solve the problems of small amount of dust adsorption and storage, not durable, aging of plastic nets, etc., and achieve enhanced dust collection. Excellent capacity, suitable mesh density, and thorough dust removal and filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

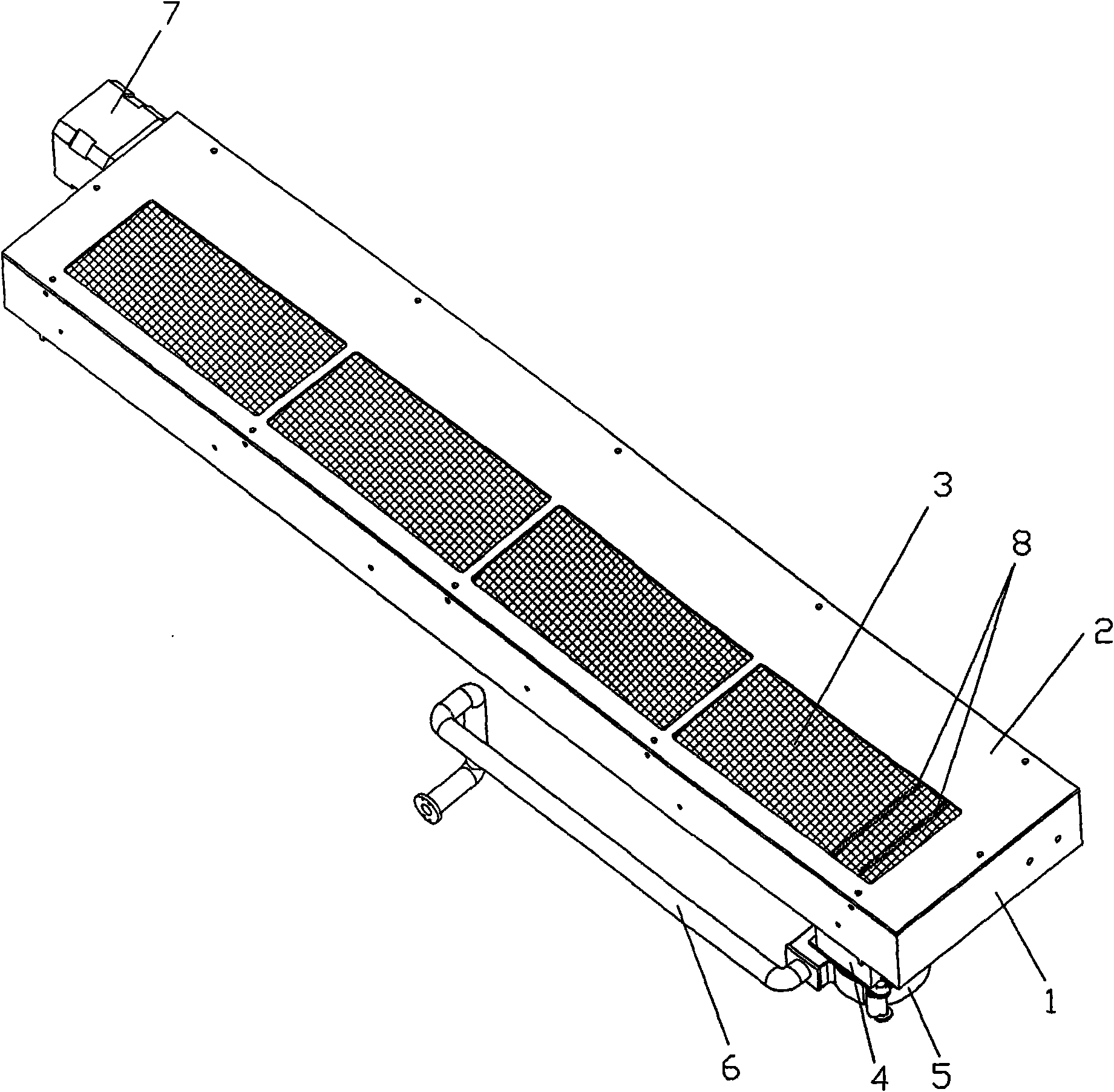

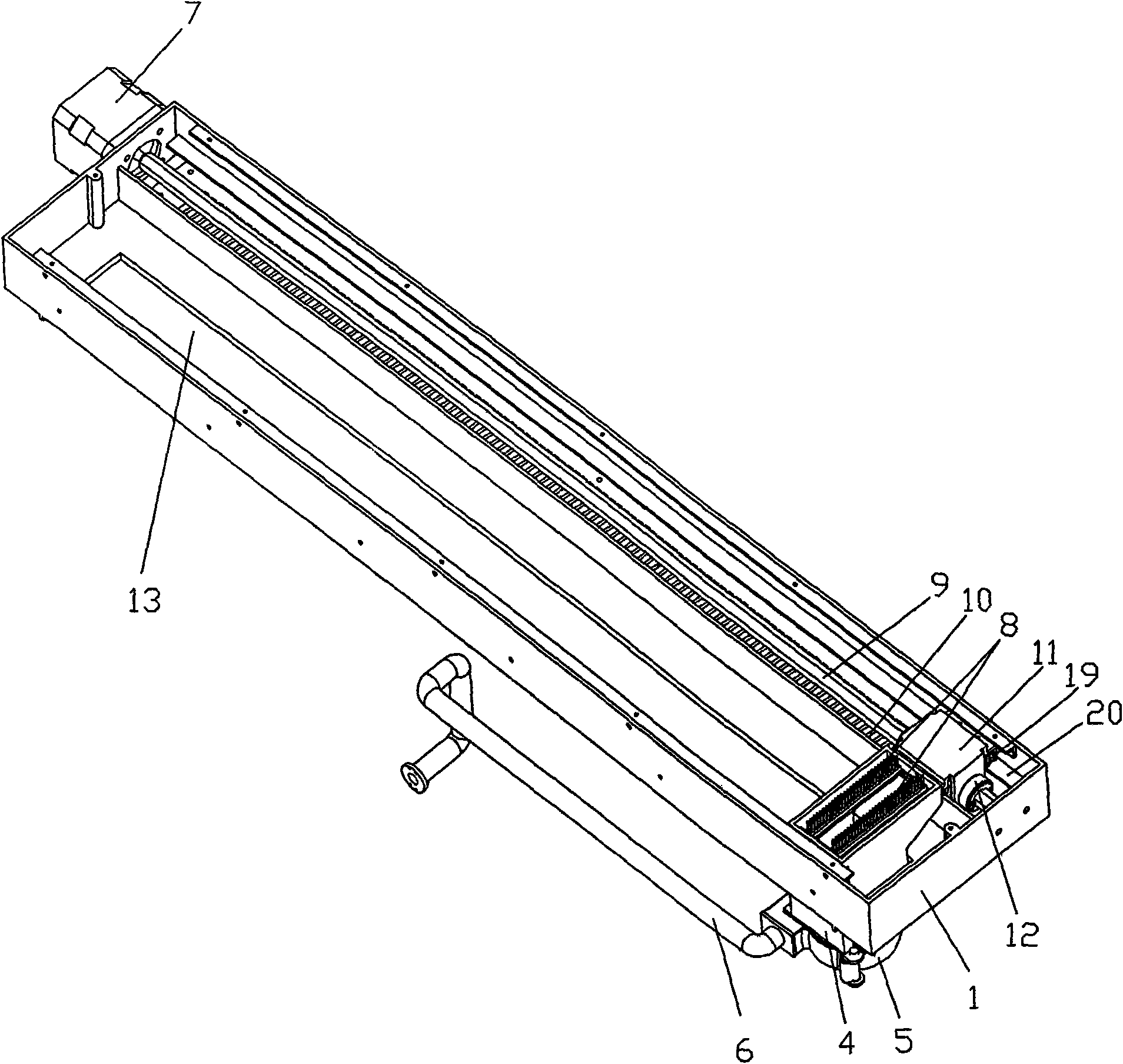

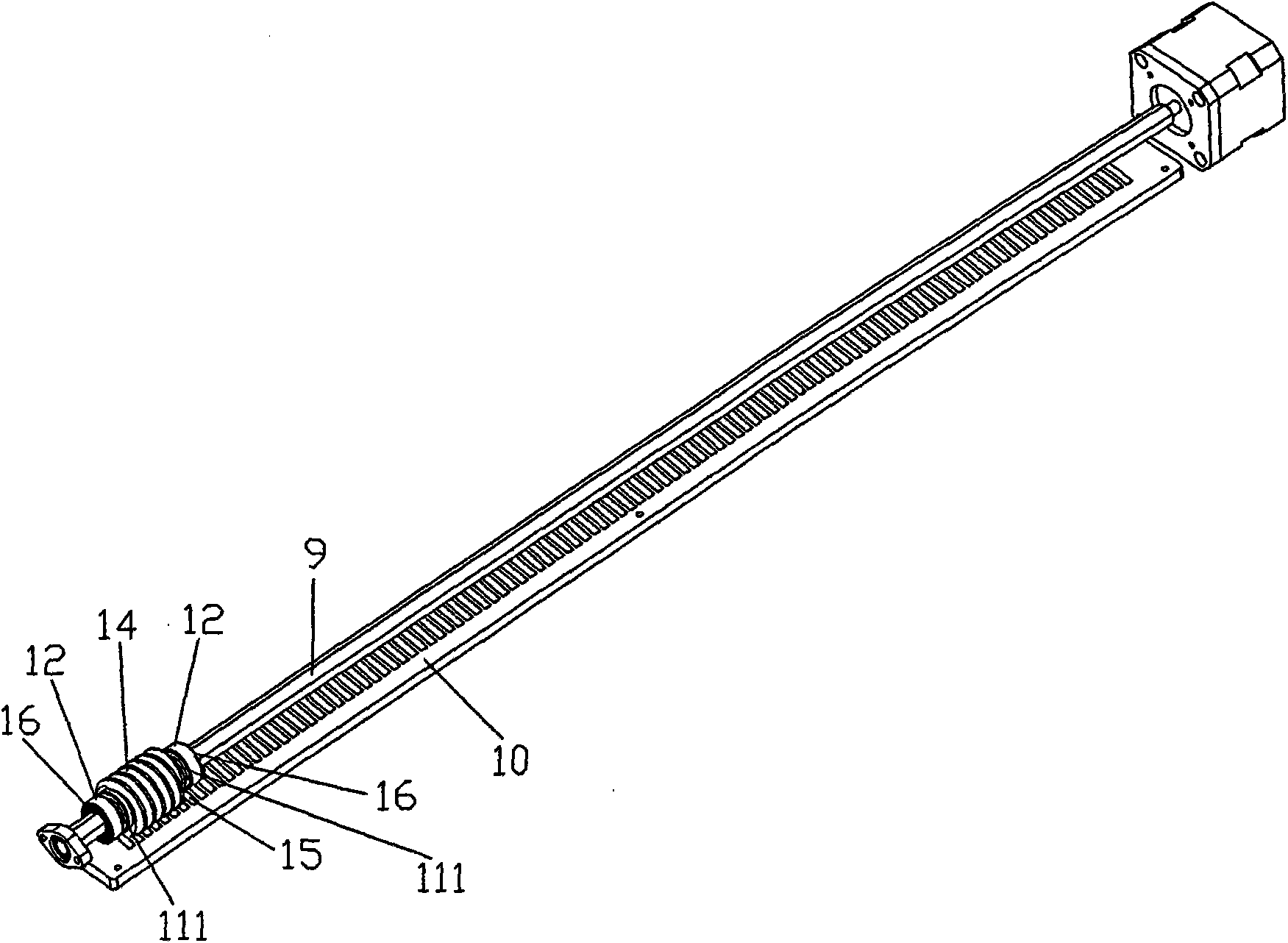

[0016] refer to Figure 1 to Figure 5 , a kind of automatic dedusting filtering device of the present invention, comprises fixed box 1, is positioned at the air inlet 13 of fixed box 1 bottom, is located at the motor 7 of fixed box 1 one end, and described fixed box 1 is separated into two by a baffle plate 18 The cavity, the air inlet 13 is located in one cavity, the cavity where the air inlet is located is provided with a dust removal isolation unit, and the other cavity is provided with a reciprocating movement mechanism unit. The reciprocating mechanism unit includes a transmission guide rod 9 connected to the output shaft of the motor 7, a guide bar 10 arranged in parallel with the transmission guide rod 9, and the transmission guide rod 9 is longitudinally slidably sleeved with a The turbine 14 rotated by the transmission guide rod 9, the guide bar 10 is evenly spaced with through holes 15, the through holes 15 match the spiral teeth of the turbine 14, and the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com