Fan blade frame and fan blade manufactured by same

A frame and blade technology, applied in the field of wind blades, can solve the problems of wind blades not being able to absorb more wind energy, low working efficiency of wind blades, low energy utilization rate, etc., to achieve high wind energy utilization rate, cost reduction, and contact surface many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

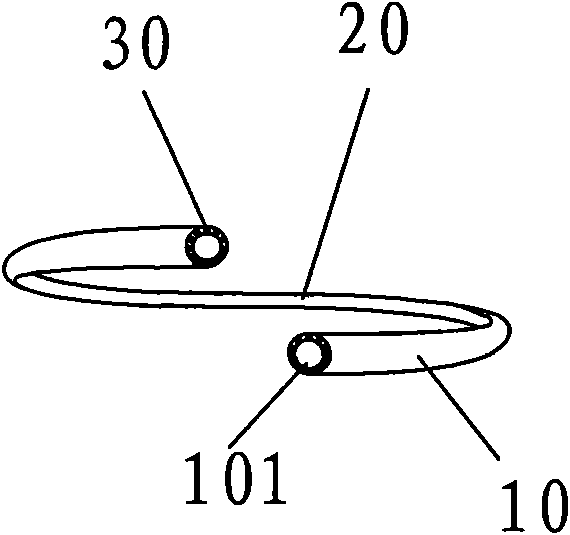

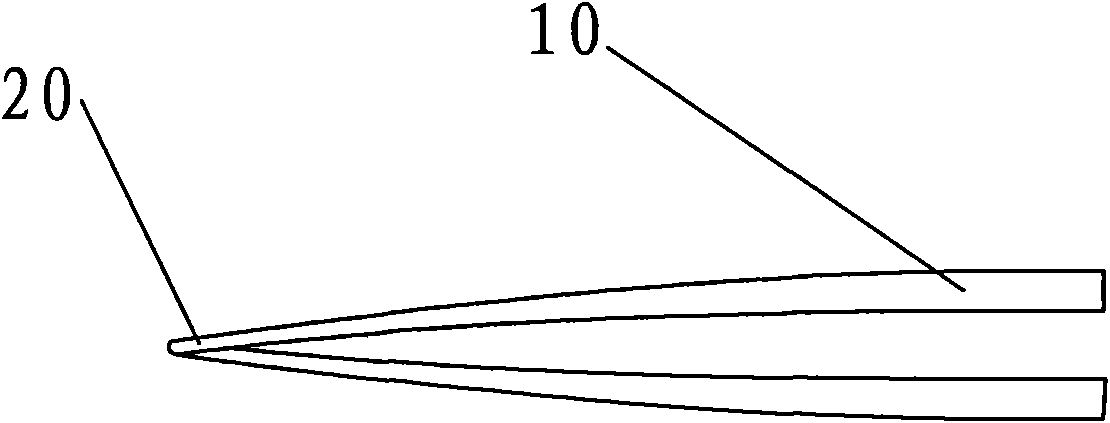

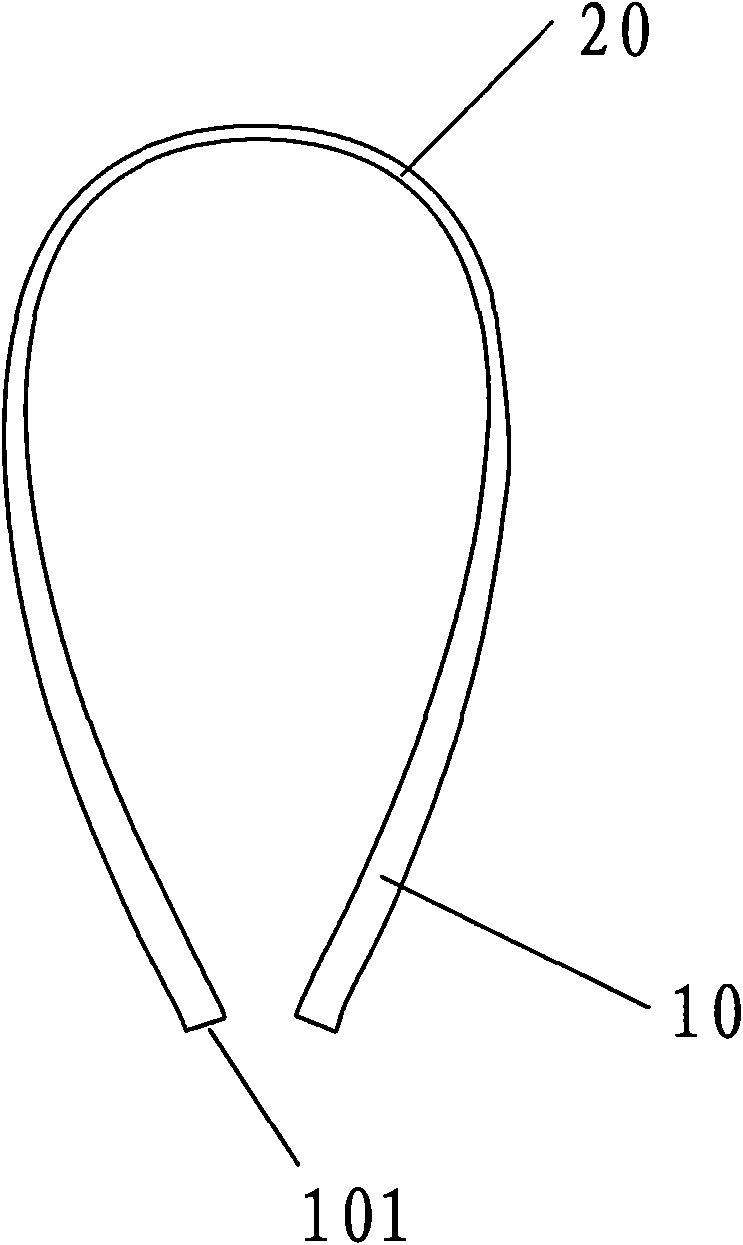

[0026] The present invention will be further described below with specific embodiments in conjunction with the drawings, see Figure 1-9 :

[0027] Fan blade frame. The frame includes a support rod 10 and a cross beam 20. The central axis of the frame has a through hole. The support rod 10 is a unequal-diameter arc structure and has a rotating shaft connecting end 101 to the middle outer diameter of the cross beam 20. With the wall thickness gradually reduced, the ratio of the outer diameter of the end surface of the connecting end 101 of the support rod 10 and the rotating shaft to the middle part of the beam 20 is 10:1, and the ratio of the wall thickness is 4:1. The beam 20 is U-shaped arc body, the end surface of the shaft connecting end 101 of the support rod 10 is provided with a plurality of connecting holes 30 fixedly connected with the shaft, the support rod 10 of the frame is twisted up and down to form a frame with a twisted shape, and the through hole is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com