Large diameter steel bar connecting sleeve

A technology of connecting sleeves and connecting sleeves for steel bars, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of wasting resources, affecting the next process, and directly processing progress, so as to save construction site land and reduce equipment The effect of investment and product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

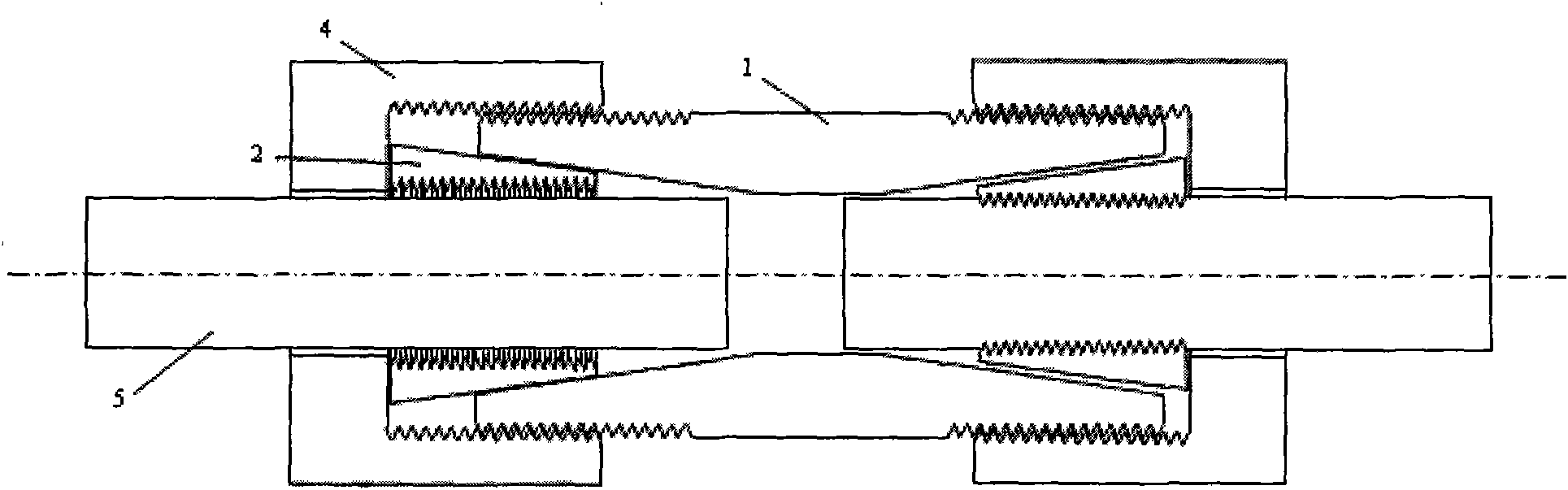

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

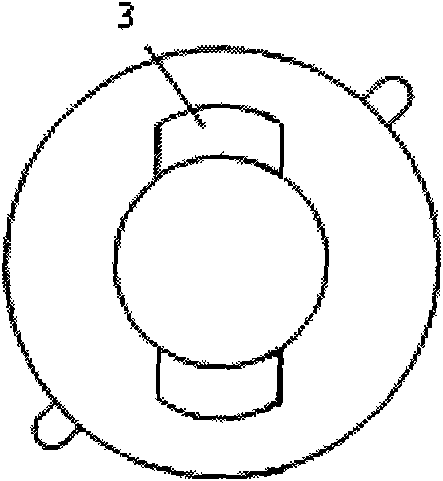

[0020] Depend on Figure 1-10 It can be seen that when connecting the thick-diameter steel bars 5 (above Φ16) coaxially, the two ends of the two steel bars 5 to be connected are respectively penetrated into the fastening sleeve 4, and then inserted into the connecting sleeve 1 , the end of the steel bar 5 is located about 10mm from the center line of the connecting sleeve 1, and then the tapered clip 2 is inserted into the tapered groove 3, and then the fastening sleeve 4 is initially screwed onto the connecting sleeve 1, so that The steel bar will not slide. Finally, use a special torque wrench to screw the fastening sleeve 4 to the specified final torque value. During the tightening process of the fastening sleeve 4, the tapered clip 2 is tightened along the tapered groove 3. Continuously advancing, the fine teeth on the clip are continuously pressed into the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com