Method for producing high-activity lactic acid bacteria agent by two-step drying method

A technology of lactic acid bacteria agent and drying method, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, and drying solid materials, etc., can solve the problems of long time consumption of microorganisms, cell autolysis, ice crystal expansion, etc., and reduce load and operation time , Improve production efficiency and reduce equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

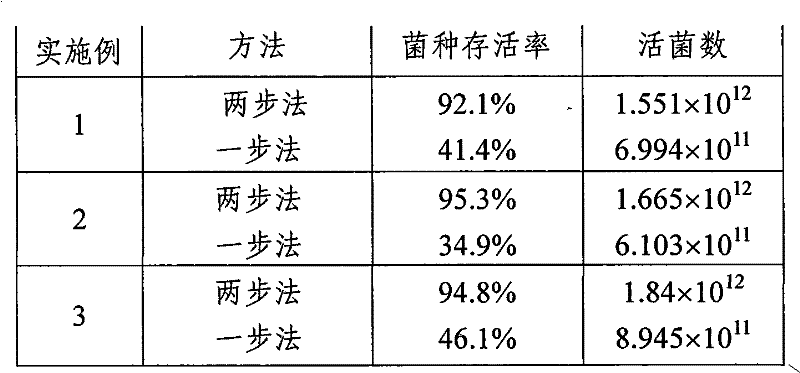

Embodiment 1

[0021] 1. Preparation of lactic acid bacteria sludge. After the lactic acid bacteria have been cultured at high density, the fermentation liquid is centrifuged at 3500 rpm for 15 minutes with a tubular centrifuge, and the supernatant is poured to obtain the sludge. Take out the sludge and put it in a container, and add a protective agent to the sludge according to the process requirements. Mix well.

[0022] 2. Vacuum drying of lactic acid bacteria slime. The prepared lactic acid bacteria slime was placed in a vacuum drying oven for vacuum drying, the vacuum degree was kept below 500 Pa, the vacuum drying temperature was 40° C., and the vacuum drying was performed for 6 hours.

[0023] 3. Vacuum freeze-drying of lactic acid bacteria slime. The lactic acid bacteria slime after vacuum drying was pre-frozen in an ultra-low temperature refrigerator, the freezing temperature was -70°C, and the freezing time was 40 minutes. The pre-frozen bacteria slime is quickly put into the va...

Embodiment 2

[0025] 1. Preparation of lactic acid bacteria sludge. After the lactic acid bacteria have been cultured at high density, the fermentation broth is centrifuged at 4000 rpm for 12 minutes with a tubular centrifuge, and the supernatant is poured to obtain the sludge. Take out the sludge and put it in a container, and add a protective agent to the sludge according to the process requirements. Mix well.

[0026] 2. Vacuum drying of lactic acid bacteria slime. The prepared lactic acid bacteria slime was placed in a vacuum drying oven for vacuum drying, the vacuum degree was kept below 500 Pa, the vacuum drying temperature was 45° C., and the vacuum drying was performed for 4 hours.

[0027] 3. Vacuum freeze-drying of lactic acid bacteria slime. The lactic acid bacteria sludge after vacuum drying is pre-frozen in an ultra-low temperature refrigerator, the freezing temperature is -60°C, and the freezing time is 90 minutes. The pre-frozen bacteria slime is quickly put into the vacuu...

Embodiment 3

[0029] 1. Preparation of lactic acid bacteria sludge. After the lactic acid bacteria have been cultured at high density, the fermentation broth is centrifuged at 5000 rpm for 5 minutes with a tubular centrifuge, and the supernatant is poured to obtain the sludge. Take out the sludge and put it in the container, and add a protective agent to the sludge according to the process requirements. Mix well.

[0030] 2. Vacuum drying of lactic acid bacteria slime. The prepared lactic acid bacteria slime was placed in a vacuum drying oven for vacuum drying, the vacuum degree was kept below 500 Pa, the vacuum drying temperature was 25° C., and the vacuum drying was performed for 20 hours.

[0031] 3. Vacuum freeze-drying of lactic acid bacteria slime. The lactic acid bacteria slime after vacuum drying was pre-frozen in an ultra-low temperature refrigerator, the freezing temperature was -80°C, and the freezing time was 30 minutes. The pre-frozen bacteria slime is quickly put into the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com