Method for extracting beta-hyskon, starch, protein and grease from oat

A technology of glucan and protein, which is applied in the field of protein and oil, extraction of β-glucan and starch, can solve the problems of environmental pollution, low production efficiency and high cost, and achieve easy source of raw materials, simple method and reduction of waste of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

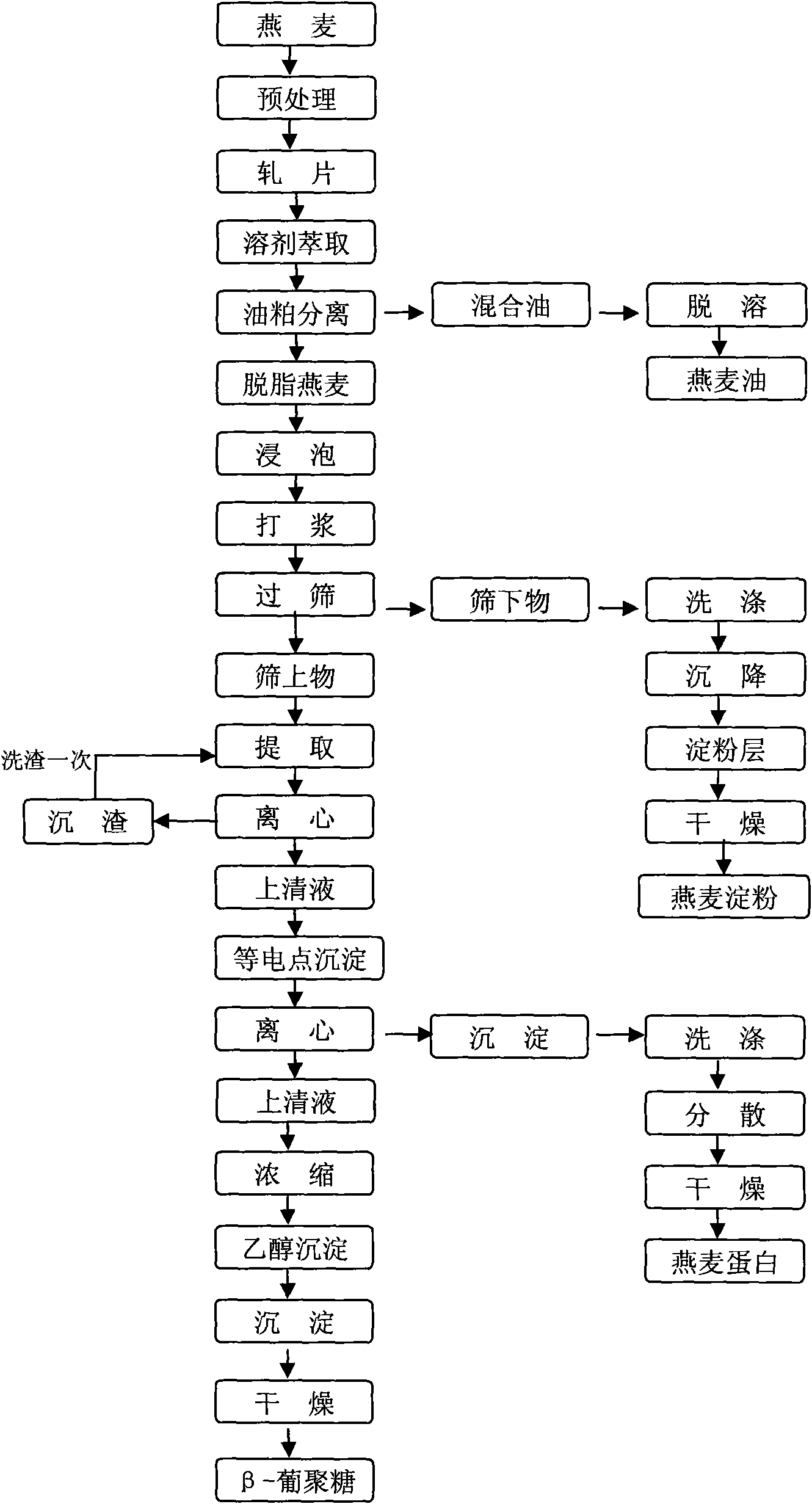

[0034] Embodiment 1, the wet production process of co-extraction of each component (beta-glucan, starch, protein and oil) in oat

[0035] 1. Preparation

[0036] 1) Raw material pretreatment: Clean the commercially available naked oat grains to remove impurities and oats containing lemma; water and moisten the wheat, and control the moisture content of oat grains to 18% (mass percentage), and the moisture content in oat grains is tested according to GB / T 21305-2007 The conventional method for the determination of moisture in grains and grain products is carried out; then use microwaves to inactivate the enzymes in the oat grains after moistening, and control the microwave power to 10W / g, 80s; 1. Rolling the oat grains after enzyme inactivation, and controlling the thickness of the rolling sheets to 0.3 mm, to obtain oatmeal.

[0037] 2) Degreasing: Send the oatmeal into the oil extraction device, and extract it three times with No. 4 solvent (the main component is a mixture ...

Embodiment 2

[0066] Embodiment 2, the wet production process of co-extraction of each component (beta-glucan, starch, protein and oil) in oat

[0067] 1. Preparation

[0068] 1) Raw material pretreatment: Clean the commercially available naked oat grains to remove impurities and oats containing lemma; water and moisten the oat grains to control the moisture content of the oat grains to 17% (mass percentage); Enzymes in the oat grains are inactivated by controlling the microwave power at 8W / g for 100s; the moistened and enzyme-inactivated oat grains are flaked with a roller flaker, and the thickness of the flakes is controlled to be 0.4mm to obtain oat flakes.

[0069] 2) Degreasing: send the oatmeal into the oil extraction device, and extract it with No. 4 solvent for 3 times, the extraction temperature is controlled at 25.0°C, the pressure is 0.6MPa, and the supernatant (containing oil) and precipitate (containing degreased oatmeal) are collected;

[0070] The method of extracting 3 time...

Embodiment 3

[0090] Embodiment 3, wet production process of each component (beta-glucan, starch, protein and oil) co-extraction in oat

[0091] 1. Preparation

[0092] 1) Raw material pretreatment: Clean the commercially available naked oat grains to remove impurities and oats containing lemma; water and moisten the oat grains to control the moisture content of the oat grains to 16% (mass percentage); Enzymes in the oat grains are inactivated by controlling the microwave power at 12W / g for 60s; the moistened and enzyme-inactivated oat grains are flaked with a roller flaker, and the thickness of the flakes is controlled to be 0.5mm to obtain oat flakes.

[0093] 2) Degreasing: put the oatmeal into the oil extraction device, extract it with No. 4 solvent for 3 times, control the extraction temperature at 20.0°C, and the pressure at 0.5MPa, collect the supernatant (containing oil) and precipitate (containing degreased oatmeal);

[0094] The method of extracting 3 times is consistent with tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com