Back-wash filtering spiral deslagging machine

A technology of slag discharger and screw, which is applied in the field of mechanical parts cleaning equipment, can solve the problems of low working efficiency, unguaranteed filtration quality, and low degree of automation, etc., and achieves compact structure, saving equipment internal space, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

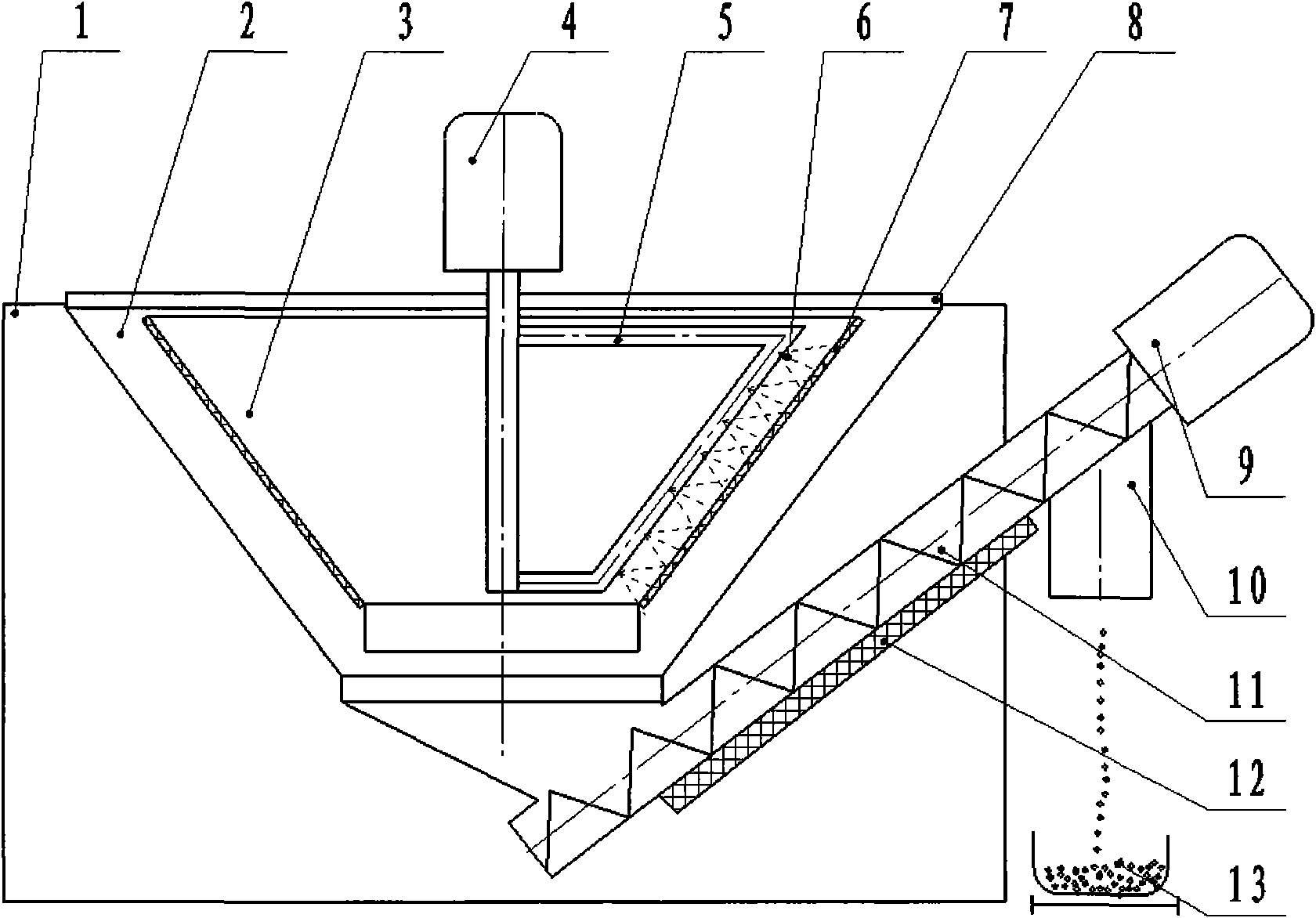

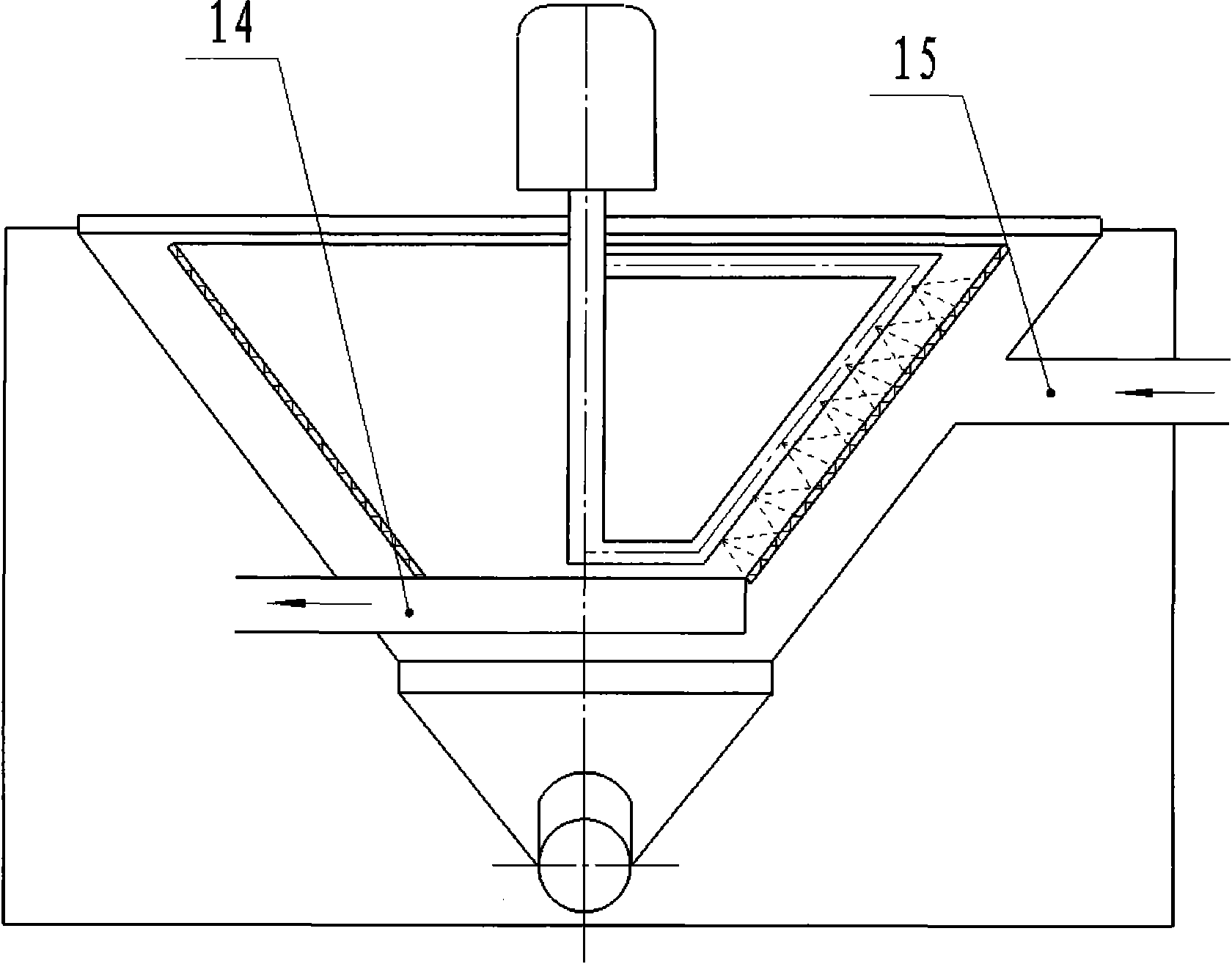

[0009] Such as figure 1 As shown, the present invention includes a clean water tank 1, a spiral slag discharger 10, a cleaning bucket 2 is fixed in the clean water tank 1, a water inlet pipe 15 communicating with the cleaning chamber is installed on one side of the cleaning bucket 2, and a filter cone is arranged in the cleaning bucket 2 The bucket 3 and the filter cone bucket 3 are fixed in the cleaning tank 1 through the mounting plate. The inside of the filter cone bucket 3 communicates with the clean water tank 1. There are a plurality of nozzles 6 . When working, the reducer is energized to drive the nozzle to rotate, and the cleaning fluid ejected from the nozzle washes the filter screen in all directions.

[0010] The cleaning bucket 2 and the filter cone 3 are funnel-shaped, the bottom of the cleaning bucket 2 is connected with the slag discharger, and the inside of the filter cone 3 is connected with the clean water tank 1 .

[0011] Filter cone bucket 3 is assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com