Information recording medium and method for manufacturing the same

A technology for information recording and media, applied in the manufacture of optical record carriers, temperature recording methods, optical record carriers, etc., can solve the problems of lower C/N ratio, lower recording and reproduction characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

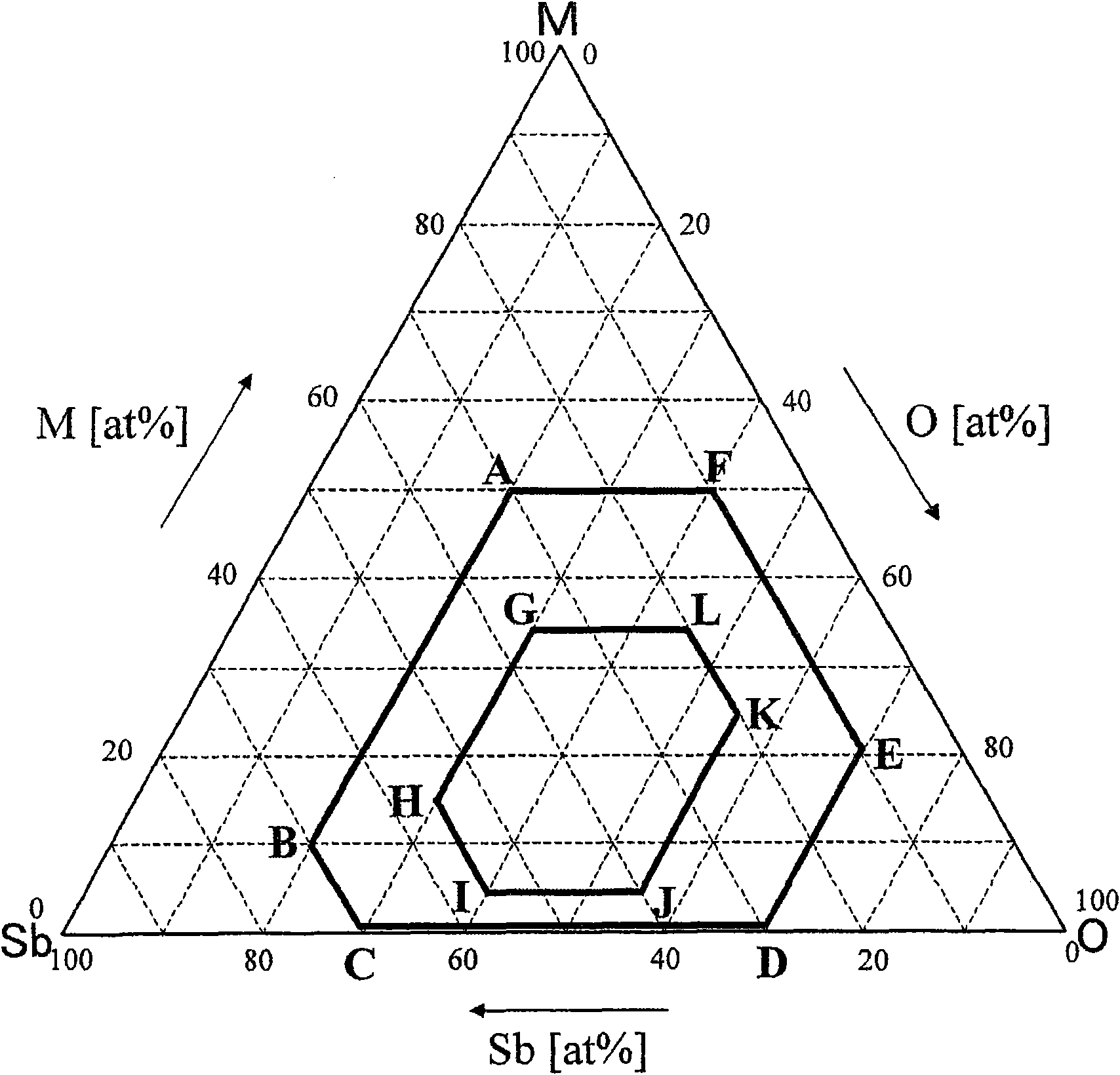

[0115] In Example 1, the influence of the composition of the recording layer on the C / N ratio and reproduction durability was investigated when a Sb—O—Ge-based material was used as the recording material. A plurality of information recording media (optical discs) each having a different composition of the recording layer were prepared as samples and evaluated. The details are shown below.

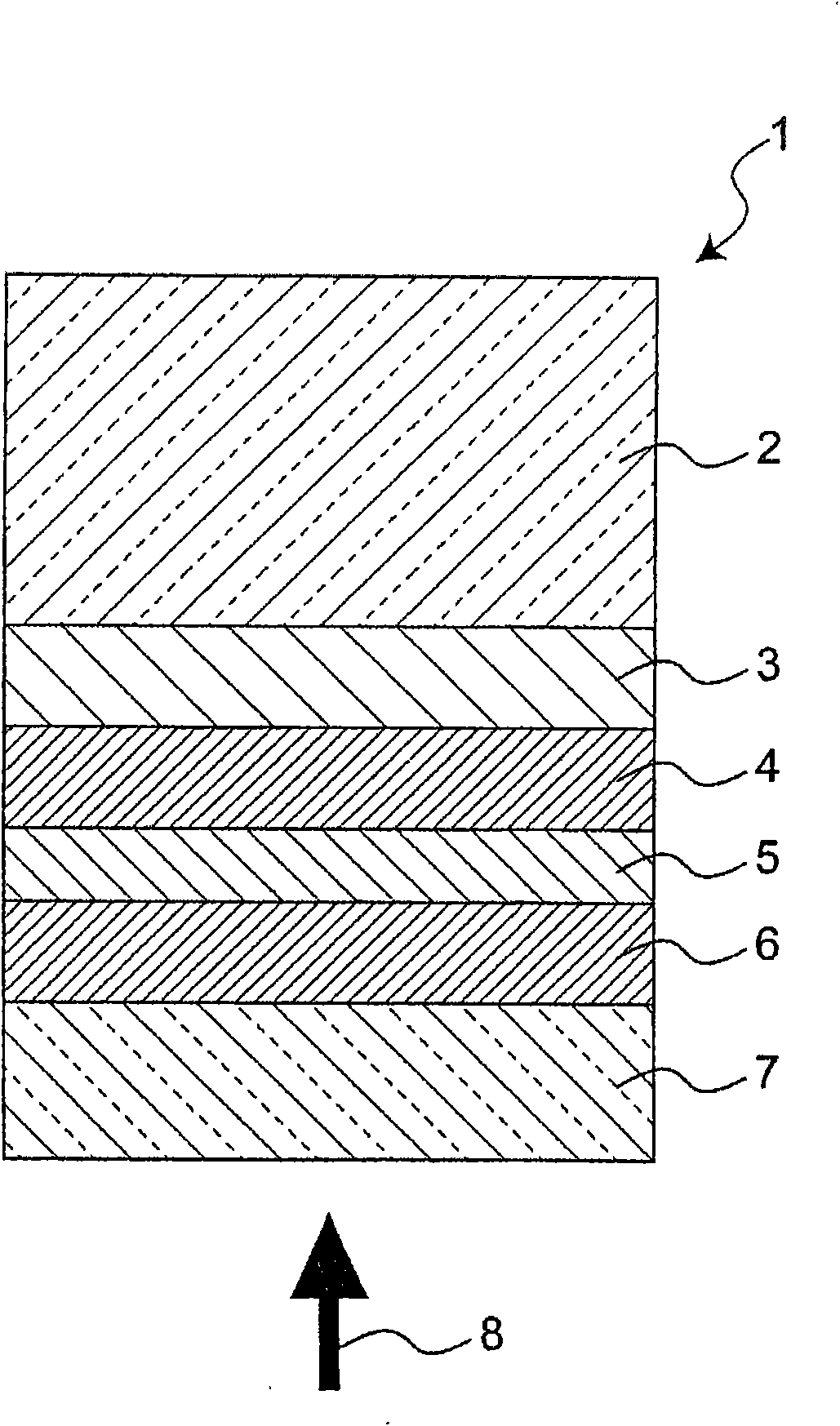

[0116] In this example, the production has figure 2 An information recording medium 1 having the configuration shown. A substrate made of polycarbonate resin was used as the substrate 2 . The substrate 2 has a diameter of 12 cm and a thickness of 1.1 mm, and has guide grooves on one surface. The guide grooves had a groove pitch of 0.32 μm and a groove depth of 20 nm.

[0117] Using an Al-Ni (atomic ratio 96.0:4.0) target, an Al-Ni reflective layer 3 with a thickness of 80 nm was formed on the surface of the substrate 2 on the side where the grooves were formed by sputtering. Next, usi...

Embodiment 2

[0135] In embodiment 2, to use Sb-O-Zn series material, Sb-O-Ni series material, Sb-O-Te series material, Sb-O-C series material, Sb-O-Cu series material, Sb-O-Ge - Zn-based materials, Sb-O-Ge-Ni-based materials, Sb-O-Ge-Te-based materials, Sb-O-Ge-C-based materials, and Sb-O-Ge-Cu-based materials are used as recording materials to form recording layers The C / N ratio and reproduction durability of the recording medium (disk) were evaluated. When the composition of the recording layer is a ternary system, set Sb:O:M=50:40:10; when it is a quaternary system, set Sb:O:M1:M2=45:35:10: 10. The film composition of the sample (only the composition of the recording layer is different from Example 1), the film formation conditions of each layer, and the evaluation method of the disc are the same as those described in Example 1. Table 2 shows the evaluation results of the discs.

[0136] [Table 2]

[0137] plate

Composition of record layer [at%]

C / N ratio

regen...

Embodiment 3

[0141] In embodiment 3, adopt Sb-O-M series material (here, Sb-O-Ge system material is used as a representative example) to constitute the recording layer of the information recording medium having two layers of information layers, and in the same manner as in embodiment 1, the recording Effect of layer composition on C / N ratio and playback durability of recording medium (optical disk).

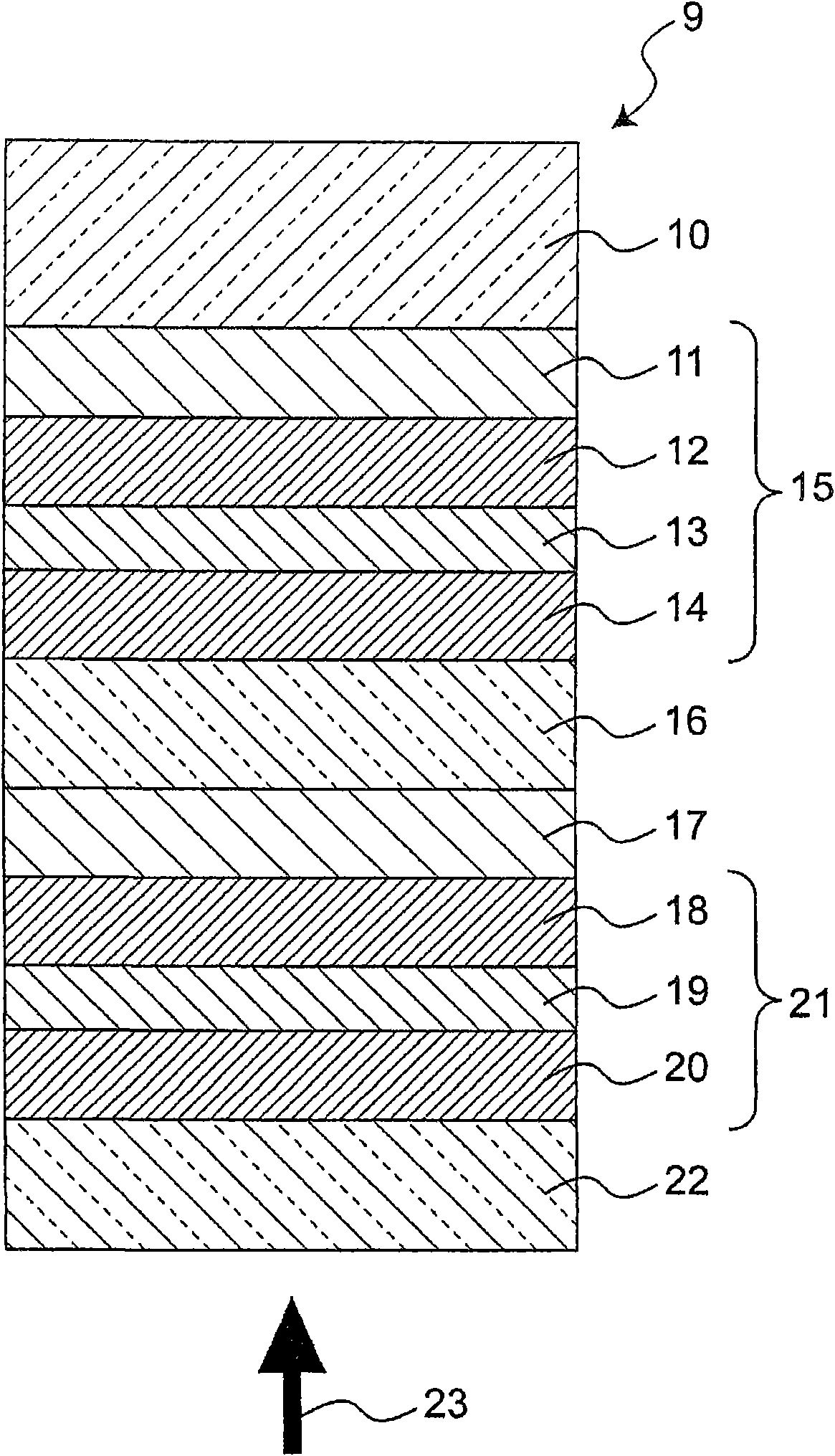

[0142] made with image 3 An information recording medium of the configuration shown. A substrate made of polycarbonate resin was used as the substrate 10 . The substrate had a diameter of 12 cm and a thickness of 1.1 mm, and had guide grooves on one surface. The guide grooves had a groove pitch of 0.32 μm and a groove depth of 20 nm.

[0143] The first information layer 15 is formed on the surface of the substrate 10 on which the grooves are formed. The first information layer 15 has a reflective layer 14 , a first dielectric layer 12 , a recording layer 13 , and a second dielectric laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com