Working machine

A technology for working machines and machinery, applied in the field of working machines, can solve problems such as inability to cut off, and achieve the effects of preventing voltage drop, realizing fuel consumption, and realizing exhausted carbon dioxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

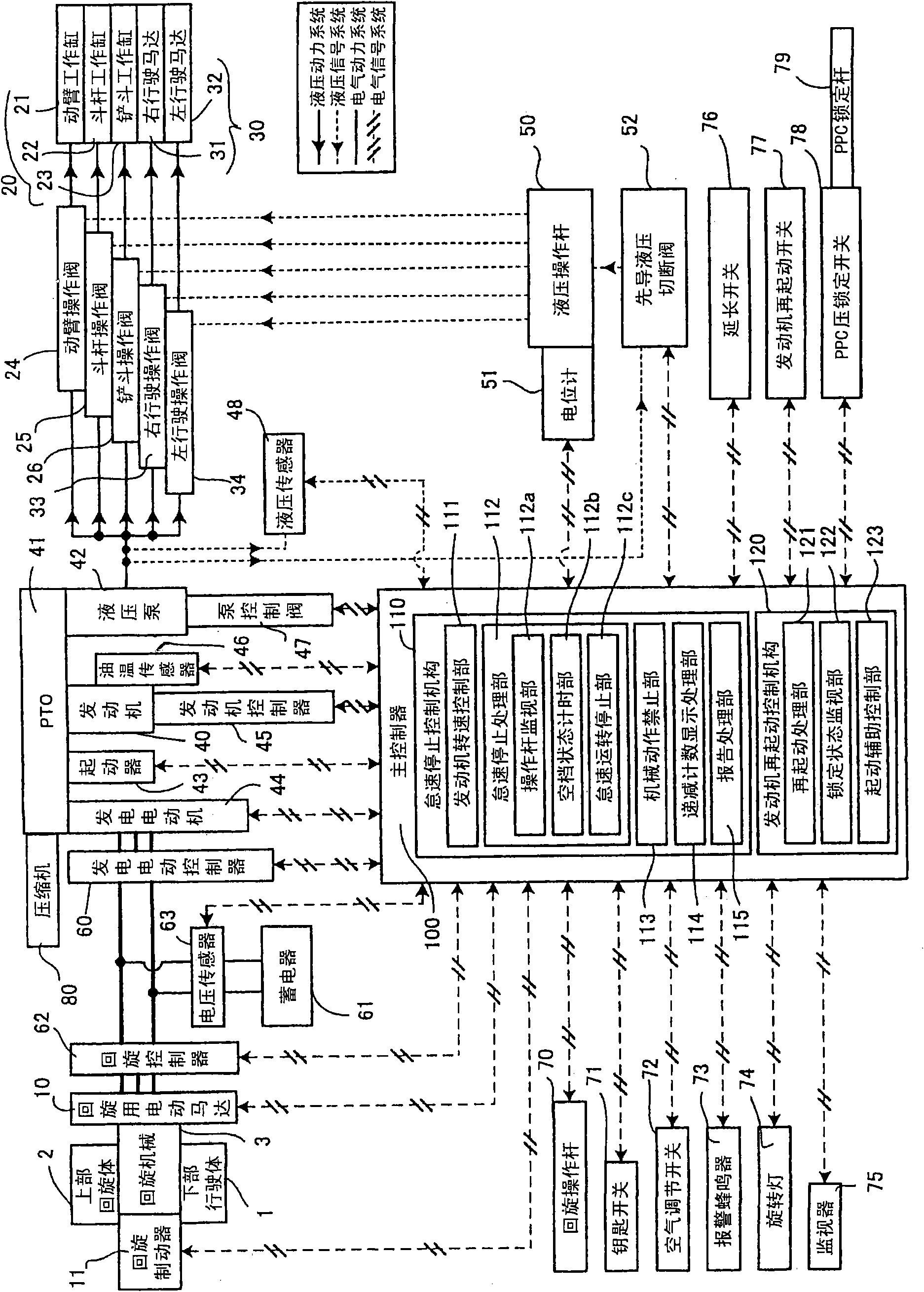

[0030] figure 1 It is a figure which shows the working machine of the embodiment of this invention. The work machine illustrated here is equipment for construction work such as a hydraulic excavator, and includes an undercarriage 1 and an upper revolving structure 2 . The undercarriage 1 travels on left and right crawler belts (not shown). The upper revolving structure 2 is disposed so as to be rotatable with respect to the undercarriage 1 via a revolving machine 3 constituted between the upper revolving structure 2 and the undercarriage 1 . Although not explicitly shown in the figure, the revolving machine 3 includes, for example, a revolving track and a pinion gear meshed with the revolving track, and the pinion is driven by the revolving electric motor 10 as an electric actuator, thereby enabling the upper revolving body 2 to face each other. When the undercarriage 1 is swung, the upper revolving structure 2 can be mechanically prevented from turning relative to the under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com