Radiating and anti-carbon powder device of collector ring component of wound rotor motor

A winding rotor motor, collector ring technology, applied in electromechanical devices, electric components, electrical components, etc., can solve the problems of collector ring heating, toner short circuit, etc., to extend service life, solve short circuit problems, increase sealing effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

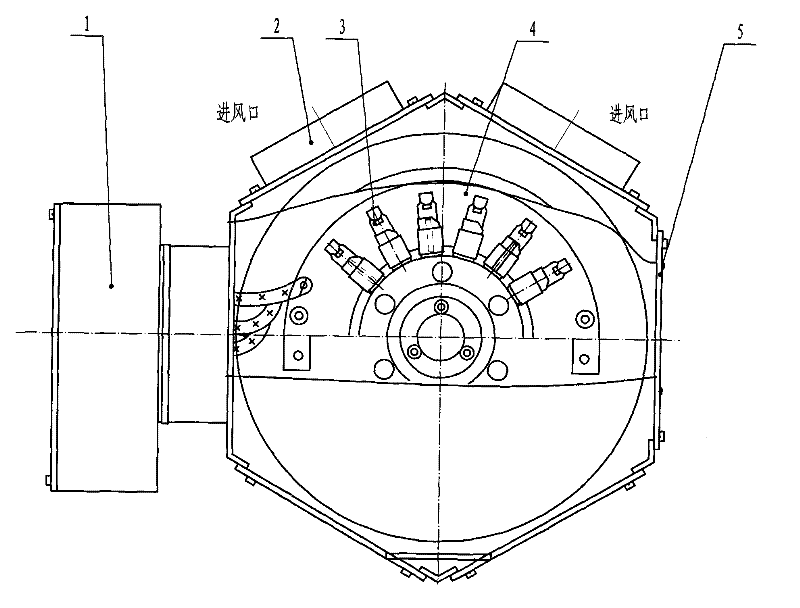

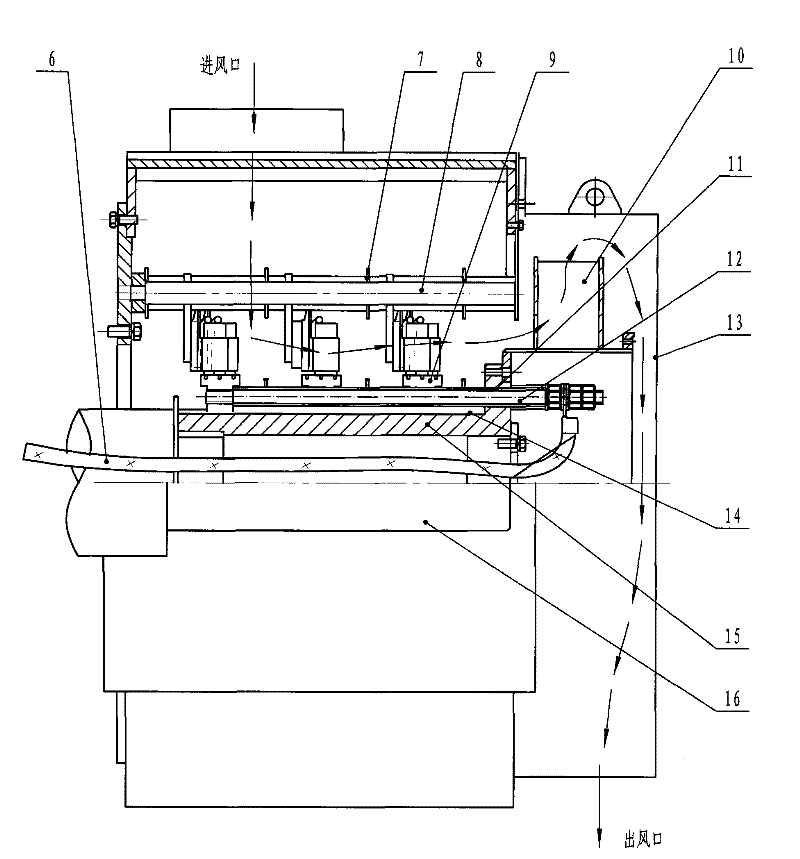

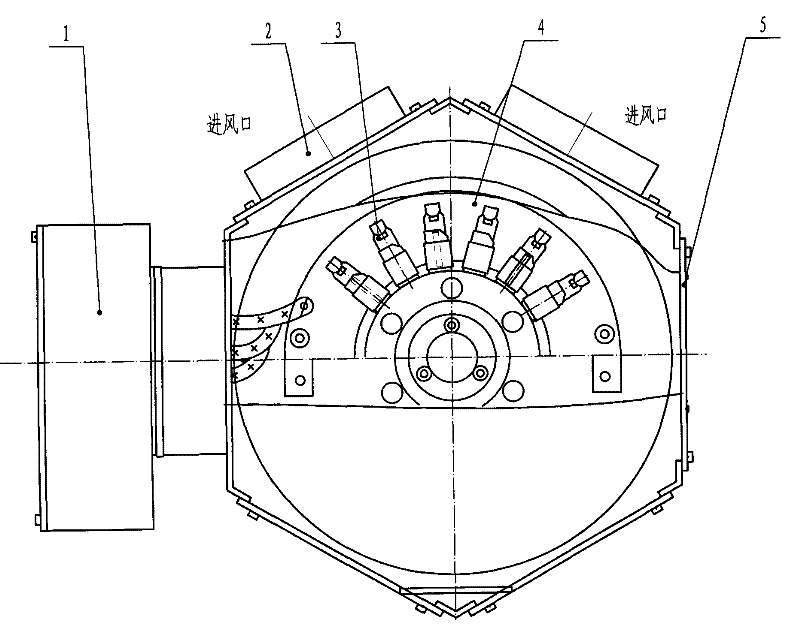

[0008] The invention provides a collector ring device for a wound rotor motor. The heat dissipation and carbon dust prevention device for the collector ring assembly of the wound rotor motor according to the invention increases the number of brushes and improves the ventilation structure on the basis of the original collector ring assembly. The sealing structure of the terminal is added to solve the short circuit problem caused by the heat of the collector ring and the carbon powder.

[0009] The collector ring heat dissipation and carbon dust prevention device of the wound rotor motor of the present invention consists of a junction box 1, a collector ring assembly support 2, a brush 3, a conductive ring 4, a lead wire 6, an insulating sleeve 14, a brush rod 8, and a collector ring 9. Fan 10, insulating pipe 11, conductive rod 12, wind cover 13, sleeve 15, and shaft 16; three identical collector rings 9 are tightly sleeved on sleeve 15 through insulating sleeve 14, and are insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com