Method for continuously forming thin film type keyboard group unit

A forming method and film forming technology, applied in the direction of electrical components, electrical switches, circuits, etc., can solve the problems of difficult rapid prototyping, thinness limitation, poor wear resistance and pressure concentration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

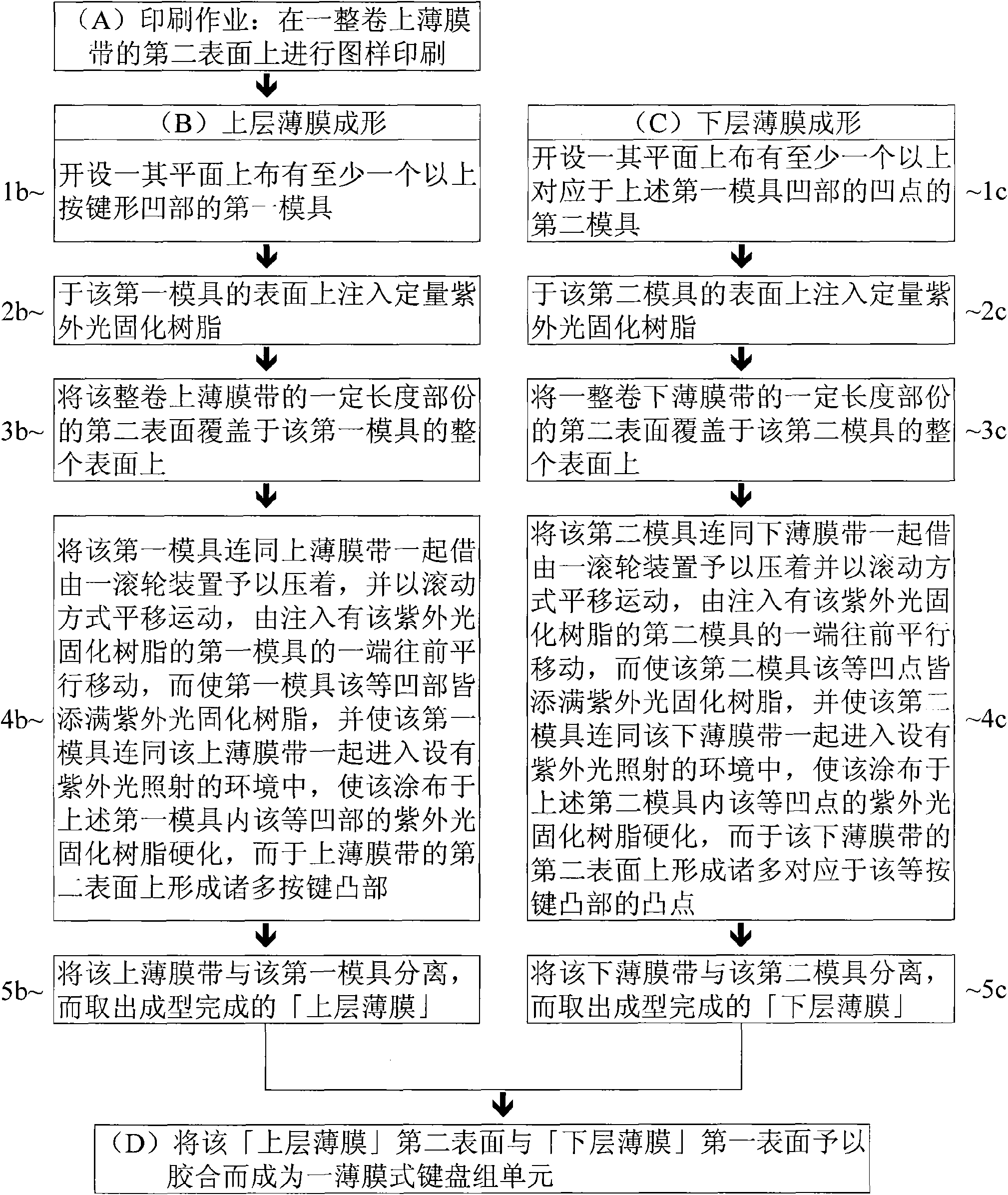

[0036] For ease of explanation and understanding, the said upper and lower film belts in the present invention refer to the film strips before forming, and the formed films are called upper and lower films; again, the upper and lower films are not in contact with each mold. The surface is the first surface, and the contact surface with each mold is the second surface. When the upper and lower films are glued together, the second surface of the upper film is glued to the first surface of the lower film.

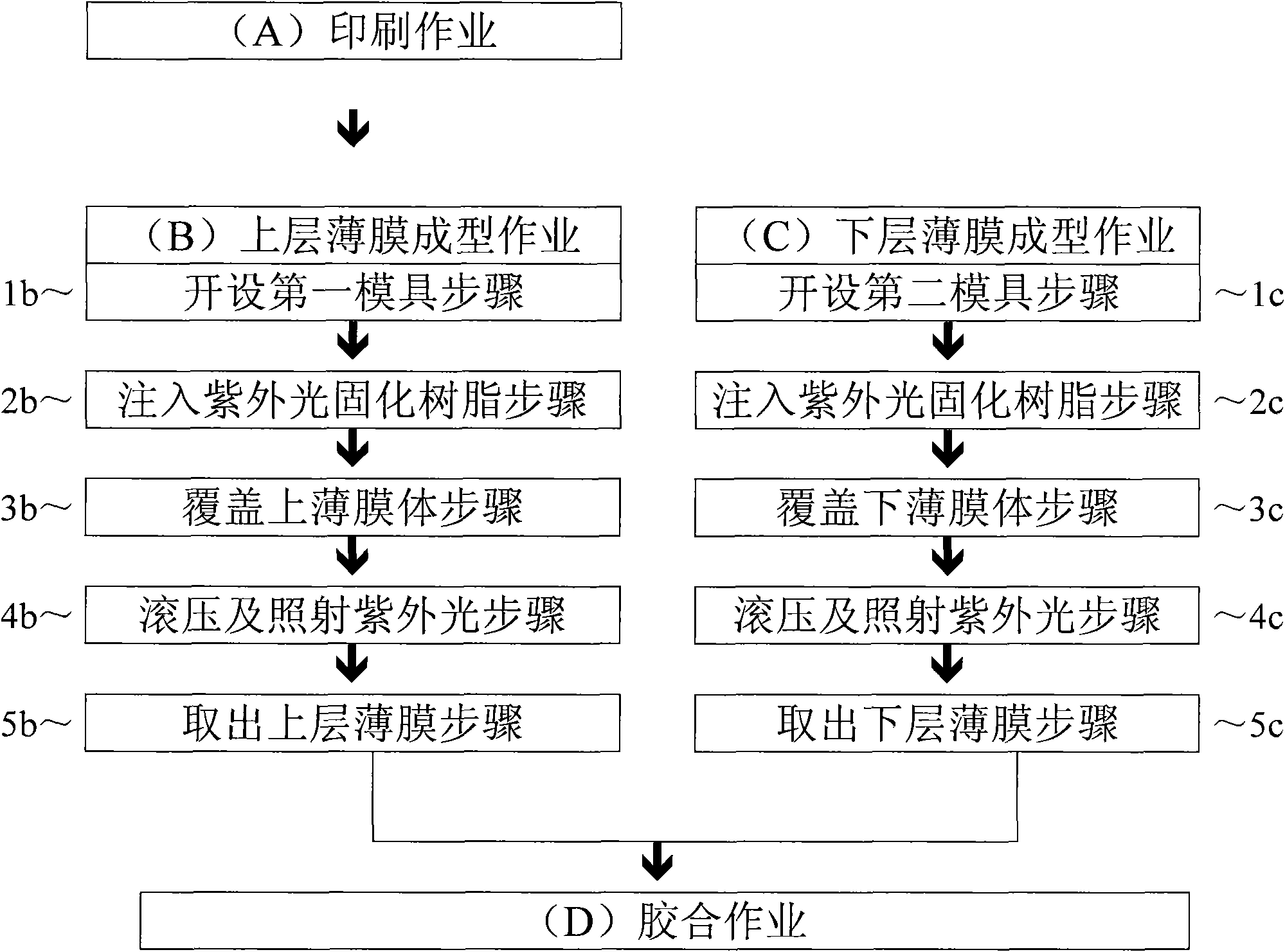

[0037] see figure 1 and Figure 1A As shown, it is a schematic diagram and a detailed description of the continuous molding method of the film keyboard unit of the present invention. The continuous molding method of the membrane keyboard unit includes printing operation (A), upper layer film forming operation (B), and lower layer film forming operation. (C) and gluing operation (D) and other steps.

[0038] Printing operation (A), printing a design on the second surface of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com