Chlorinated polyethylene used for preparation of low temperature wind energy cable and preparation method thereof

A technology of chlorinated polyethylene and wind energy, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., and can solve the problem of cold-resistant reinforcement ℃PE rubber compound with general composition, stability, impact strength, and products that cannot meet performance requirements, etc. problems, to achieve the effects of reducing quality hazards, increasing low-temperature aging strength, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Firstly, 39% CPE rubber, 12% carbon black, 18.5% talc powder, 8.5% light calcium carbonate are blended, and in an internal mixer, the temperature of the stick is 45~60℃ for 27~40min; then add sunflower Dioctyl diacid 4.3% and chlorinated paraffin 4.5%, then add 2.5% accelerator, continue mixing for 3 minutes; then blend with 1.2% paraffin, 2.0% magnesium oxide, 3.0% antimony trioxide, 2.0% decabromide , Continue to mix in the internal mixer for 3 minutes, then add 2.5% DCP vulcanizing agent to mix for 0.5 minutes in the internal mixer, and finally discharge the rubber from the internal mixer, and then unload and pack in the open mixer to obtain the finished product.

Embodiment 2

[0013] First, 37% CPE rubber, 12.5% carbon black, 17.9% talc, and 7.5% light calcium carbonate are blended, and then mixed in an internal mixer at a temperature of 45~60℃ for 27~40min; then add sunflower Dioctyl diacid 4.5% and chlorinated paraffin 5%, then add 2.0% accelerator, continue banburying for 3 minutes; then blend with 2% paraffin, 2.5% magnesium oxide, 3.5% antimony trioxide, and 2.6% decabromide , Continue to mix in the internal mixer for 3 minutes, then add 3.0% DCP vulcanizing agent and mix for 0.5 minutes in the internal mixer, and finally discharge the rubber from the internal mixer, and then unload and pack in the open mixer to obtain the finished product.

Embodiment 3

[0015] First, 40% CPE rubber, 13% carbon black, 16.2% talcum powder, 6.0% light calcium carbonate are blended, and the mixer is mixed at a temperature of 45-60°C for 27-40 minutes; then add sunflower Dioctyl diacid 6% and chlorinated paraffin 4%; then add 3.0% accelerator, continue banburying for 3 minutes; then blend with 3.0% paraffin, 1.8% magnesium oxide, 2% antimony trioxide, 1.8% decabromide , Continue to mix in the internal mixer for 3 minutes, then add 3.2% DCP vulcanizing agent and mix for 0.5 minutes in the internal mixer, and finally discharge the rubber from the internal mixer, and then unload and pack it in the open mixer to obtain the finished product.

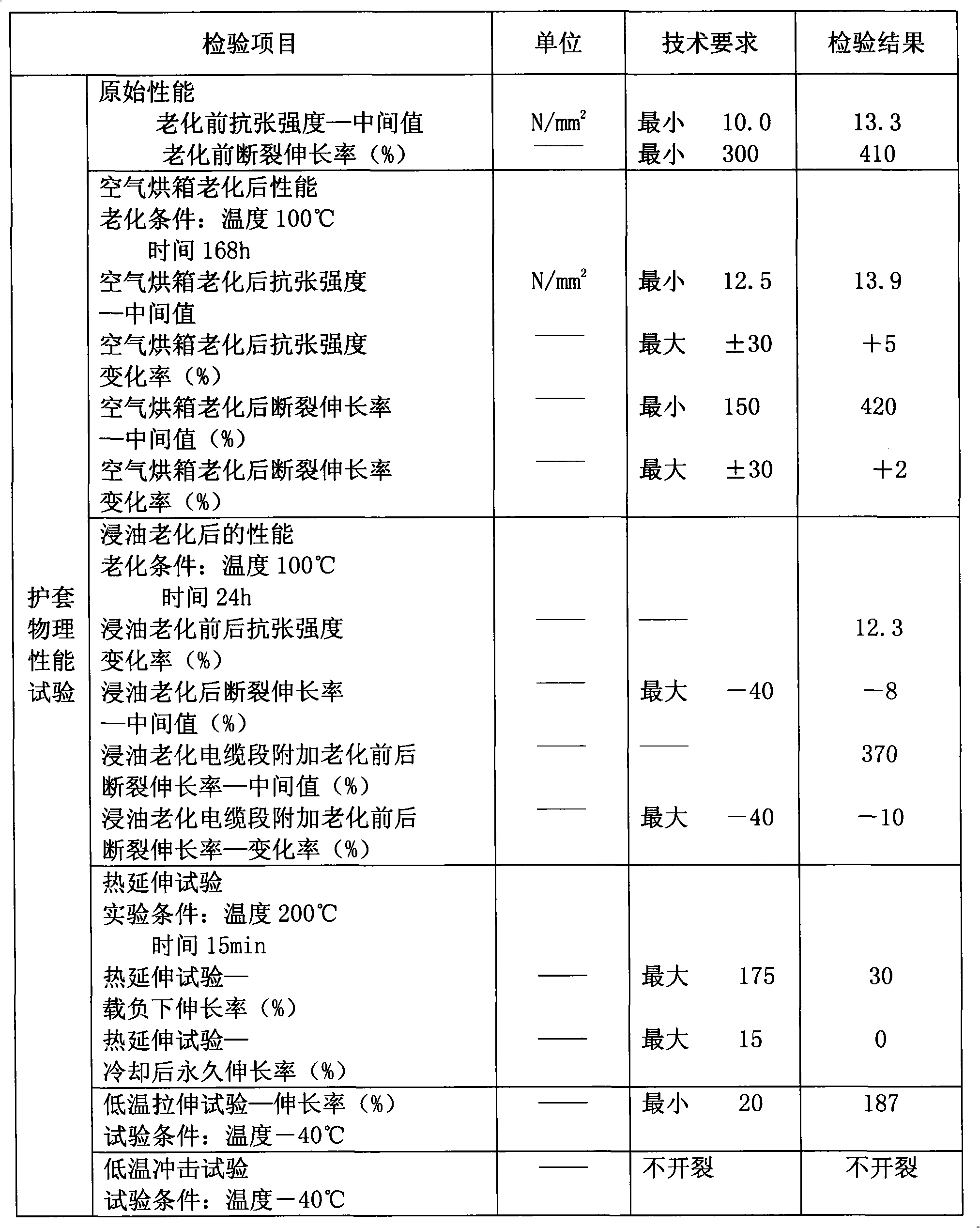

[0016] Table 1 is the technical index of Example 1. It can be seen that the performance index greatly exceeds the requirement.

[0017] Table 1: Example 1 Technical indicators of chlorinated polyethylene

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com