Preparation method of super-hydrophilic mesoporous silicon oxide films

A mesoporous silica and super-hydrophilic technology, applied in the field of functional material technology and ordered mesoporous materials, can solve the problems of not reaching the super-hydrophilic state, long preparation period, difficult practical application, etc., and achieve easy industrial production. , low cost, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

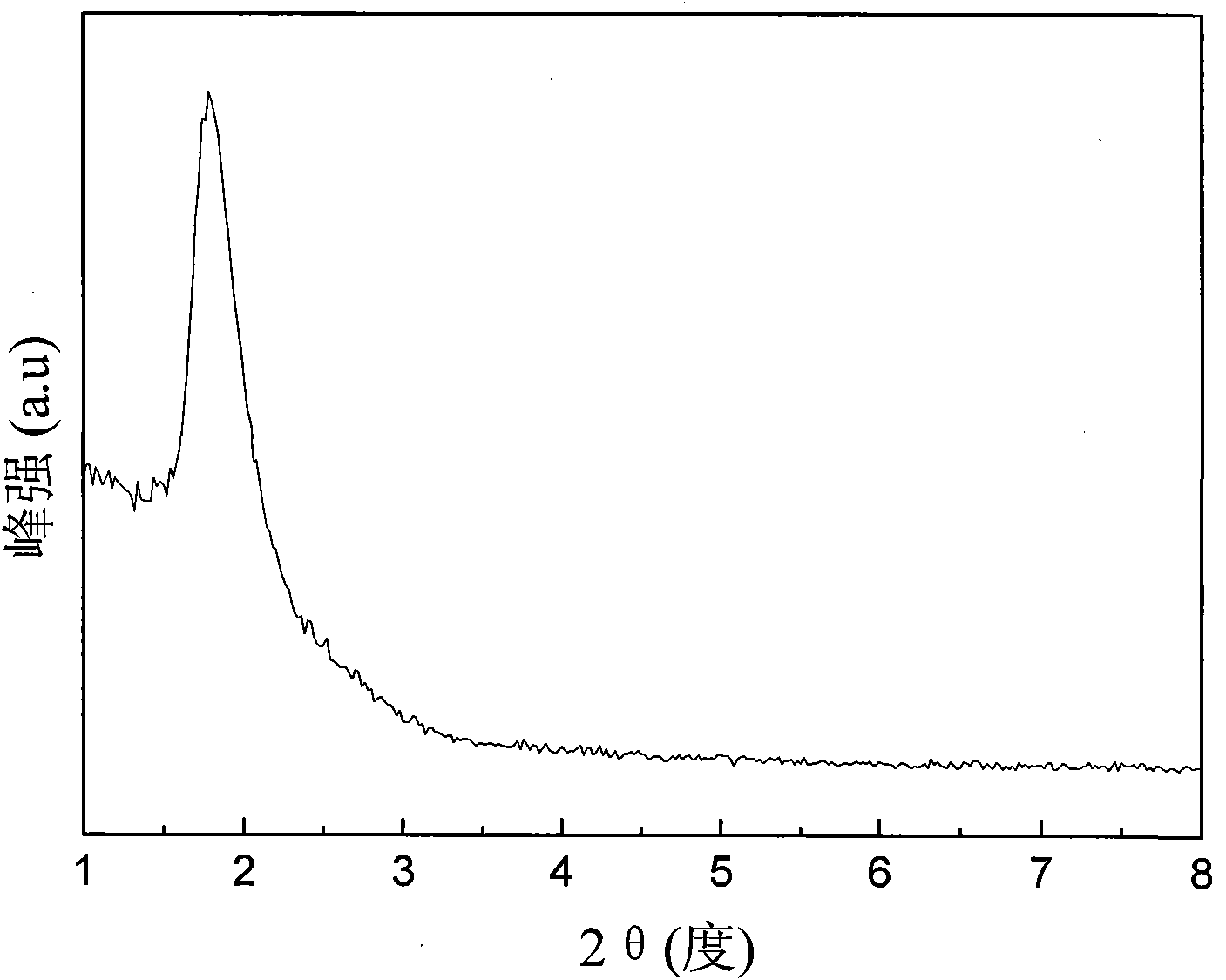

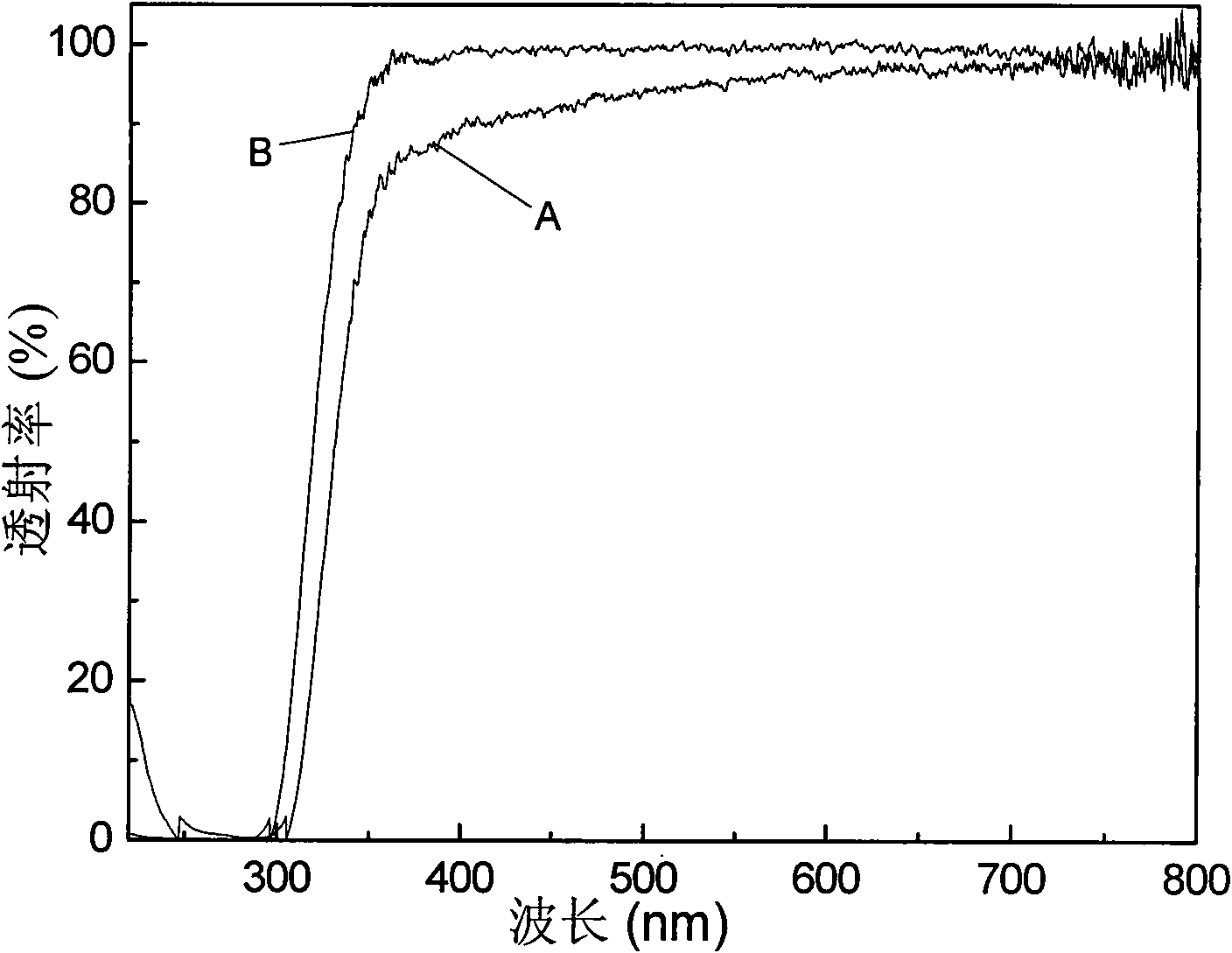

[0031] Preparation of super-hydrophilic mesoporous silicon oxide film: the method of the present invention uses a sol-gel process to prepare a mesoporous silicon oxide film by spin coating.

[0032] First place the ordinary glass in water and use ultrasonic waves with a frequency of 50Hz to clean it for 10 minutes, then wash it three times with deionized water and absolute ethanol respectively, then soak the ordinary glass in 10% NaOH solution for 20 minutes, and wash it with deionized water After cleaning 5 times, place it in an oven at 100°C for 1 hour to dry, and use it as a coating substrate;

[0033] With tetraethyl orthosilicate (TEOS) as the silicon source, polyoxyethylene (4) ether lauryl alcohol (Brij30) as the template, according to the material ratio, TEOS: Brij30: HCl: EtOH (dehydrated alcohol) = 8: 0.9:0.8:50, prepare reactants. First, the mixed solution of absolute ethanol and TEOS is added to the mixed solution of Brij30 and hydrochloric acid, the pH of the mix...

Embodiment 2

[0037] First place the ordinary glass in water and use ultrasonic waves with a frequency of 50Hz to clean it for 10 minutes, then wash it three times with deionized water and absolute ethanol respectively, then soak the ordinary glass in 15% NaOH solution for 10 minutes, and wash it with deionized water After cleaning 5 times, place it in an oven at 100°C for 1 hour to dry, and use it as a coating substrate;

[0038]With tetraethyl orthosilicate (TEOS) as the silicon source, polyoxyethylene (4) ether lauryl alcohol (Brij30) as the template, according to the material ratio, TEOS: Brij30: HCl: EtOH (dehydrated alcohol) = 8: 0.9:0.8:50, prepare reactants. First, add the mixture of absolute ethanol and TEOS to the mixture of Brij30 and hydrochloric acid, the pH of the mixture of Brij30 and hydrochloric acid is 4, and then heat it in a collector type constant temperature magnetic stirrer at 20°C at 20r / min The precursor was obtained after stirring at a stirring rate of 10 min.

...

Embodiment 3

[0042] First place the ordinary glass in water and use ultrasonic waves with a frequency of 50Hz to clean it for 10 minutes, then wash it three times with deionized water and absolute ethanol respectively, then soak the ordinary glass in 5% NaOH solution for 30 minutes, and wash it with deionized water After cleaning 5 times, place it in an oven at 100°C for 1 hour to dry, and use it as a coating substrate;

[0043] With tetraethyl orthosilicate (TEOS) as the silicon source, polyoxyethylene (4) ether lauryl alcohol (Brij30) as the template, according to the material ratio, TEOS: Brij30: HCl: EtOH (dehydrated alcohol) = 8: 0.9:0.8:50, prepare reactants. First, add the mixture of absolute ethanol and TEOS to the mixture of Brij30 and hydrochloric acid, the pH of the mixture of Brij30 and hydrochloric acid is 4, and then heat it in a collector type constant temperature magnetic stirrer at 30°C at 15r / min The precursor was obtained after stirring at the stirring rate for 20 min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com