Preparation method of electrophoretic display microcapsule containing organic silicon

An electrophoretic display and microcapsule technology, which is applied in the fields of microcapsule preparation, microsphere preparation, optics, etc., can solve the problems that cannot be reused, cannot change images in real time, and the barrier performance of electrophoretic medium needs to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

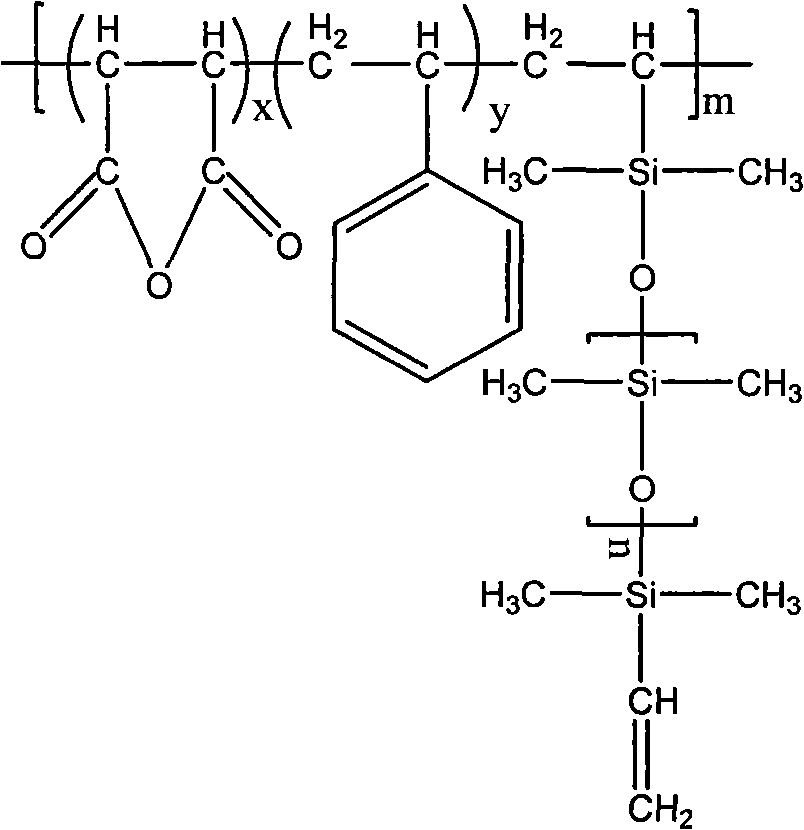

[0023] The hydrolyzate and gelatin of the vinyl silicone oil-styrene-maleic anhydride terpolymer with a number average molecular weight of 4620 are formulated into 100 grams of 0.1% aqueous solution respectively, their pH value is adjusted to 7, and kept at 40°C spare.

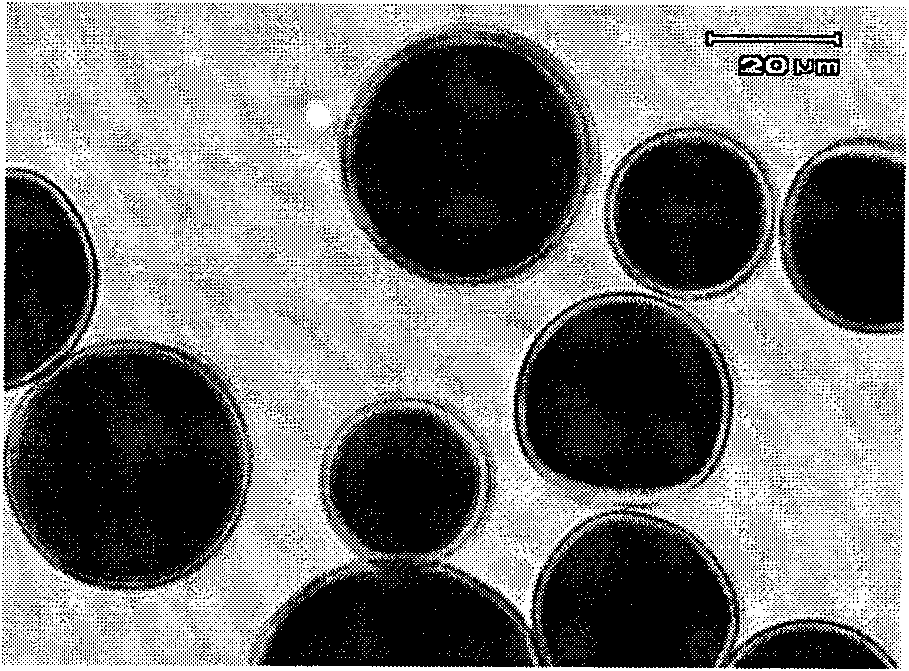

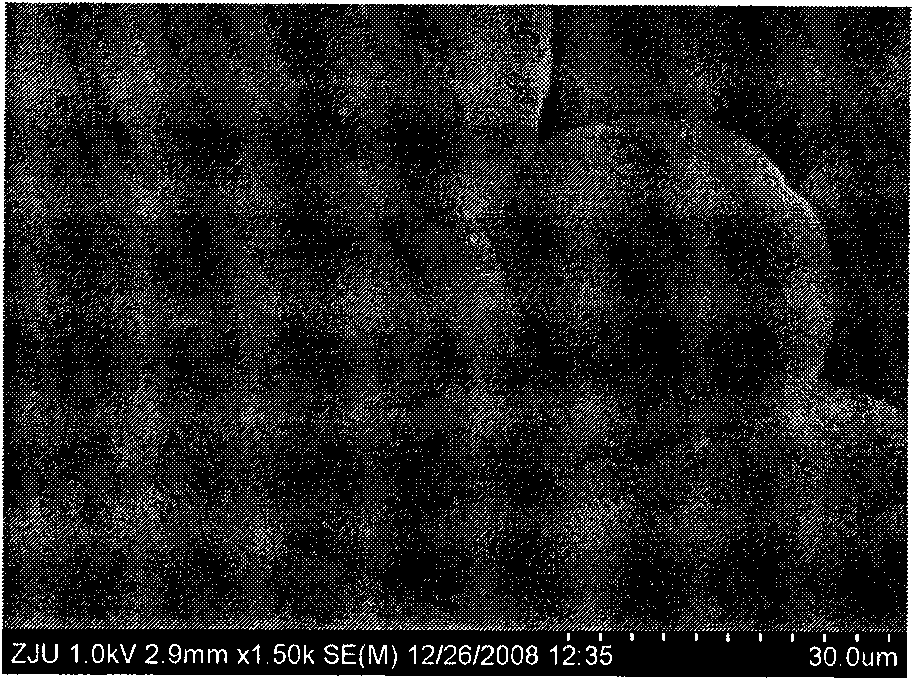

[0024] Add electrophoretic particles, dyes, and additives to tetrachloroethylene, ultrasonically vibrate at 40°C to make a uniform dispersion of 20 grams, add it to the above-mentioned silicon-containing aqueous solution, and stir for 100 minutes to obtain an O / W emulsion. Add the prepared gelatin solution into the emulsion, lower the pH value of the system to 4.5 with 0.05% acetic acid solution at 40°C, then add hot water 5 times that of the gelatin aqueous solution into the emulsion, and slowly lower the temperature to At 10°C, add 2.5 ml of 40% formaldehyde solution dropwise to the above system to cross-link the walls of the microcapsules, continue the reaction for 1 hour, add 3% sodium hydroxide solution t...

Embodiment 2

[0026] The vinyl silicone oil-styrene-maleic anhydride terpolymer hydrolyzate that number average molecular weight is 15000 is made into 100 grams of 20% aqueous solution, gelatin is made into 10 grams of 30% aqueous solution, their pH value is adjusted to 7.0, and kept at 65°C for later use.

[0027] Electrophoretic particles, dyes, and additives were added to tetrachlorethylene, and ultrasonically oscillated at 65° C. to form 23 grams of a uniform dispersion. Add it into the above-mentioned vinyl silicone oil-styrene-maleic anhydride terpolymer hydrolyzate solution, stir for 1 minute to obtain an O / W emulsion, add the prepared gelatin solution into the emulsion, and use 3 % citric acid solution to reduce the pH value of the system to 4.5, slowly lower the temperature to 0°C while stirring, add 4 ml of 40% glutaraldehyde aqueous solution to the above system dropwise to cross-link the microcapsule wall, and continue the reaction for 1 hour , adding 3% sodium hydroxide solutio...

Embodiment 3

[0029] The hydrolyzate and gelatin of the vinyl silicone oil-styrene-maleic anhydride terpolymer that the number average molecular weight is 90000 are made into 100 grams of 4% aqueous solution respectively, their pH value is adjusted to 6.5, and in 50 ℃ insulation spare.

[0030] Add electrophoretic particles, dyes, and additives to tetrachlorethylene, ultrasonically vibrate at 50°C to make 80 grams of a uniform dispersion, and add to the hydrolyzate of the above-mentioned vinyl silicone oil-styrene-maleic anhydride terpolymer solution, stirred for 20 minutes to obtain an O / W emulsion, the prepared gelatin solution was added to the emulsion, and the pH value of the system was reduced to 4.5 with 10% acetic acid solution at 50 ° C, and then 5 times the gelatin aqueous solution Add hot water into the emulsion, slowly lower the temperature to 5°C while stirring, add 100 ml of 0.02% acetaldehyde aqueous solution dropwise to the above system to cross-link the microcapsule wall, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com