Strengthening glass using coatings

A coating and glass substrate technology, applied in glass forming, glass manufacturing equipment, coating, etc., can solve the problems of increasing the overall reliability of glass and failing to ensure high Weibull modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention includes compositions and methods related to forming and applying coatings for strengthening pre-damaged glass substrates. Specifically, the invention relates to thin and ultra-thin glasses such as Corning's EAGLE TM Compositions and methods for forming and applying coatings on glass.

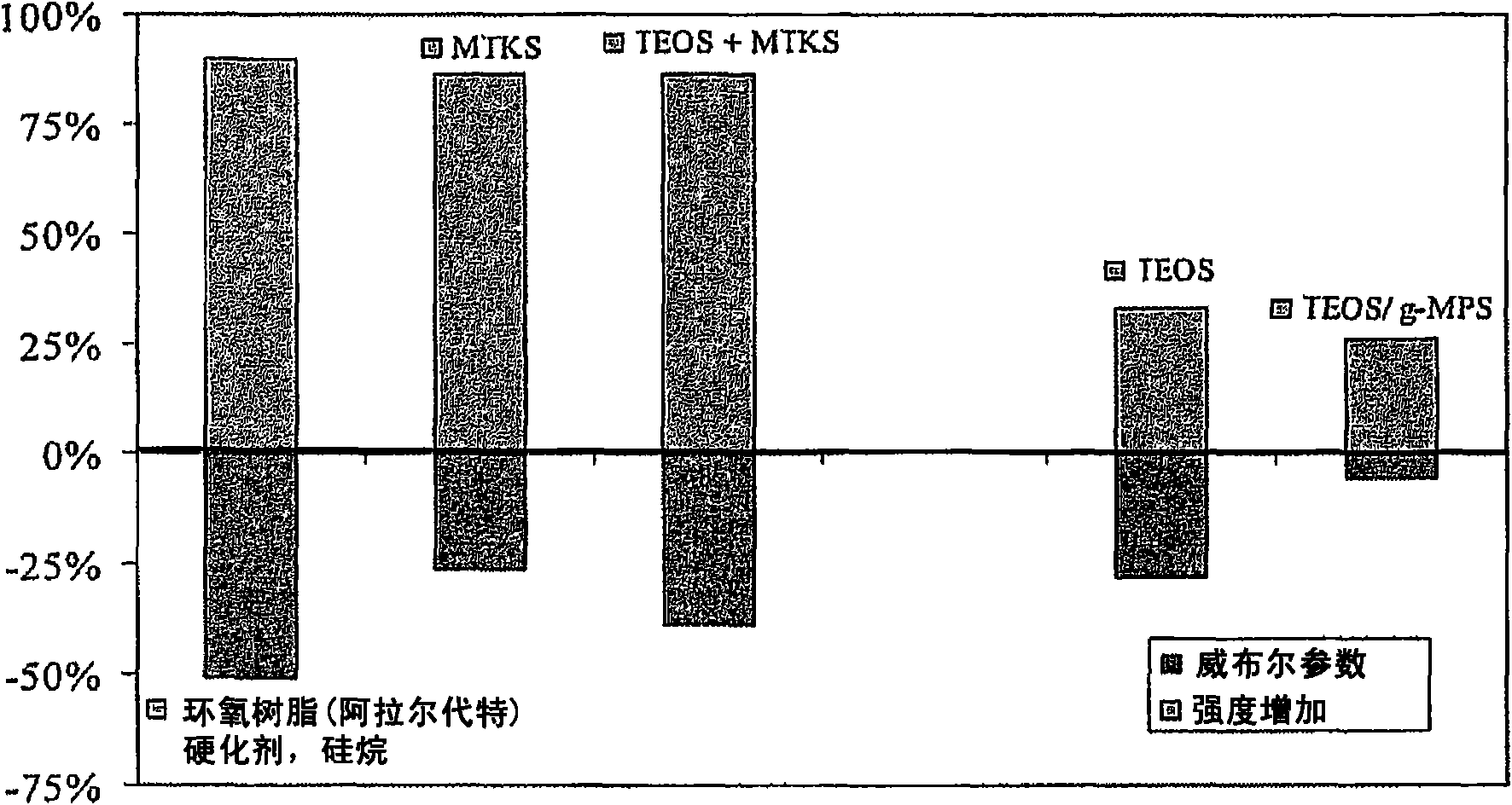

[0025]Figure 1 shows the change in Weibull modulus and the change in failure strength for coating various (different) glass substrates. All five coating / substrate combinations shown in Figure 1 were obtained according to the prior art. Although the strength of the coated glass sample was increased compared to the uncoated glass sample, the coating also caused a decrease in the Weibull parameter. Therefore, the overall strength distribution of the glass is reduced. The coatings used in the experiments leading to the data in Figure 1 were applied from aqueous solutions. In the three coatings / substrates on the left of Fig. 1, the water used for the hydrolysis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com