Automobile production information managing system

A production information and management system technology, applied in the field of automobile production information management system, can solve the problems of decision deviation, large delay, large human and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

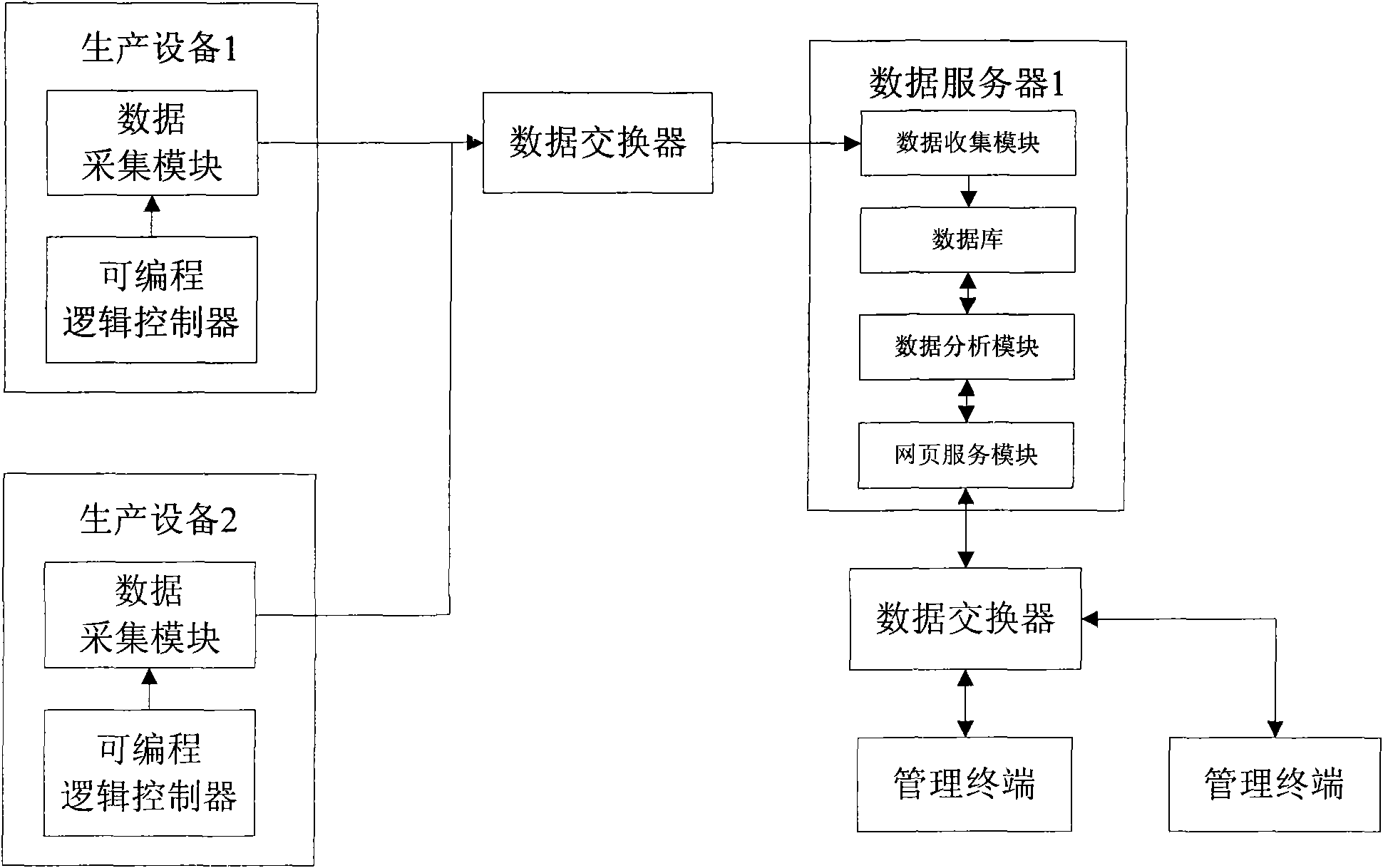

[0019] An automobile production information management system, comprising:

[0020] One or more programmable logic controllers (PLC) installed on the production equipment to control the production process, each programmable controller is connected with a data acquisition module for collecting production time, failure time, and dead time,

[0021] Data server, described data server comprises:

[0022] A data collection module, connected to the data collection module, for obtaining information collected by the data collection module;

[0023] a database for storing the information collected by the data collection module;

[0024] The data analysis module is used for analyzing the information in the database.

[0025] Wherein, a data exchanger is connected between the data collection module and the data collection module.

[0026] Wherein, the data server further includes a webpage service module connected with the data analysis module.

[0027] Wherein, one or more managemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com