Biomass water-coal-slurry slurring and combustion method and integrated system

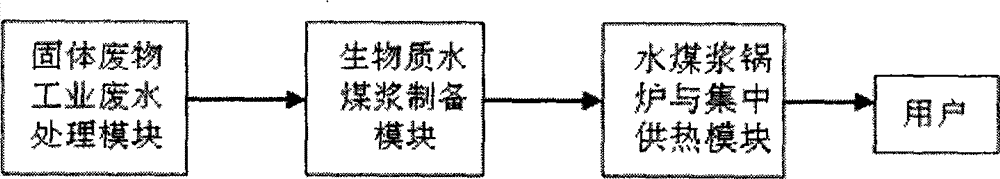

A combustion method and coal-water slurry technology, which is applied in the field of deep processing, can solve the problems not involved in the biomass coal-water slurry slurry combustion integrated system and industrial scale application, and achieve the effect of improving the comprehensive utilization efficiency of resources and simplifying the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

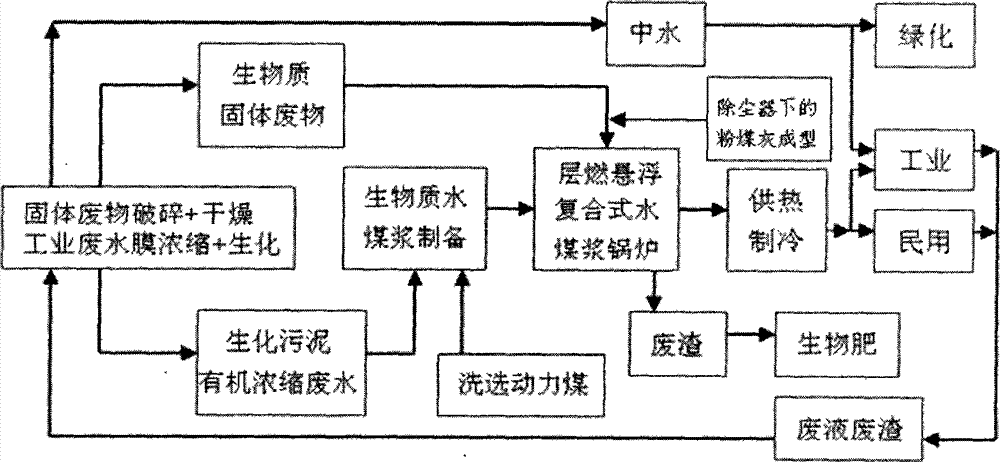

[0022] A biomass water coal slurry pulping and combustion method is to first place solid combustible waste and waste water in a solid waste industrial waste water treatment module for treatment. Among them, the solid combustible waste is crushed and dried to be used as fuel for stratification; then the industrial wastewater is processed by a high-speed centrifuge and membrane concentration treatment to form a membrane concentrate mainly composed of biochemical sludge and organic concentrated wastewater. The membrane concentrate after the concentration treatment is used for pulping, and the treated water is used for slurry adjustment or other industrial applications; and then the membrane concentrate, which is mainly composed of biochemical sludge and organic concentrated wastewater after the membrane concentration treatment, is used for washing The steam coal is prepared according to the ratio of 65% of the washed steam coal and 35% of the membrane concentrate after membrane con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com