Tobacco fig flavor prepared by microbes as well as preparation method and application thereof

A technology of figs and microorganisms, applied in application, food preparation, essential oil/spice, etc., can solve the problems of insufficient aroma quality, poor application effect, weak aroma intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the extraction of natural fig concentrated juice:

[0034] (1) Pretreatment of fresh fig fruit, drying 300Kg of fresh slices to obtain about 180Kg of dried fruit, to prevent fruit from rotting and deteriorating. (2) solvent net extraction, select to use 60% ethanol 900Kg net extraction 8 hours and change solvent four times, each solvent consumption is 2 times 360Kg of fig amount for the first time, two, three, four times its one times 180Kg, After four times of net extraction, the net liquid is naturally drained and concentrated to obtain a total of 810Kg of each net liquid storage. (3) Concentrate, utilize decompression and low-temperature distillation to concentrate the net liquid to about 180Kg and basically have no ethanol to distill, stop distillation and concentrate. In this process, 621Kg of 70% ethanol can be recovered. (4) filter, concentrate juice is filtered and obtain the fig fruit juice of 180Kg production.

Embodiment 2

[0035] Embodiment 2: the preparation of aroma-producing bacteria liquid strain:

[0036] Inoculate a strain of Bacillus licheniformis SW-1 (Bacillus licheniformis) with the preservation number CICC20006; two strains of Clostridium kluyveri SW-2 and SW-3 (Clostridium kluyveri) with the preservation numbers CICC20005 and CICC20008, respectively, inoculated on the slope In the strain activation medium, place it in an incubator at 35 ° C for 48 hours, then inoculate the cultured bacteria into a 10-liter seed tank with a weight ratio of 4%, and ferment the seed culture solution with a capacity of 7 liters, ventilate Stirring, the stirring speed during fermentation is 180r / min, and the air volume is controlled: V air / V liquid per minute: 1:0.15.

[0037] The mixture was cultured at 35° C. for 48 hours to obtain an activated seed liquid.

[0038] Activation medium for slant strains:

[0039] 20 grams of beef extract, 10 grams of yeast extract, 5 grams of sodium chloride, 10 grams of ...

Embodiment 3

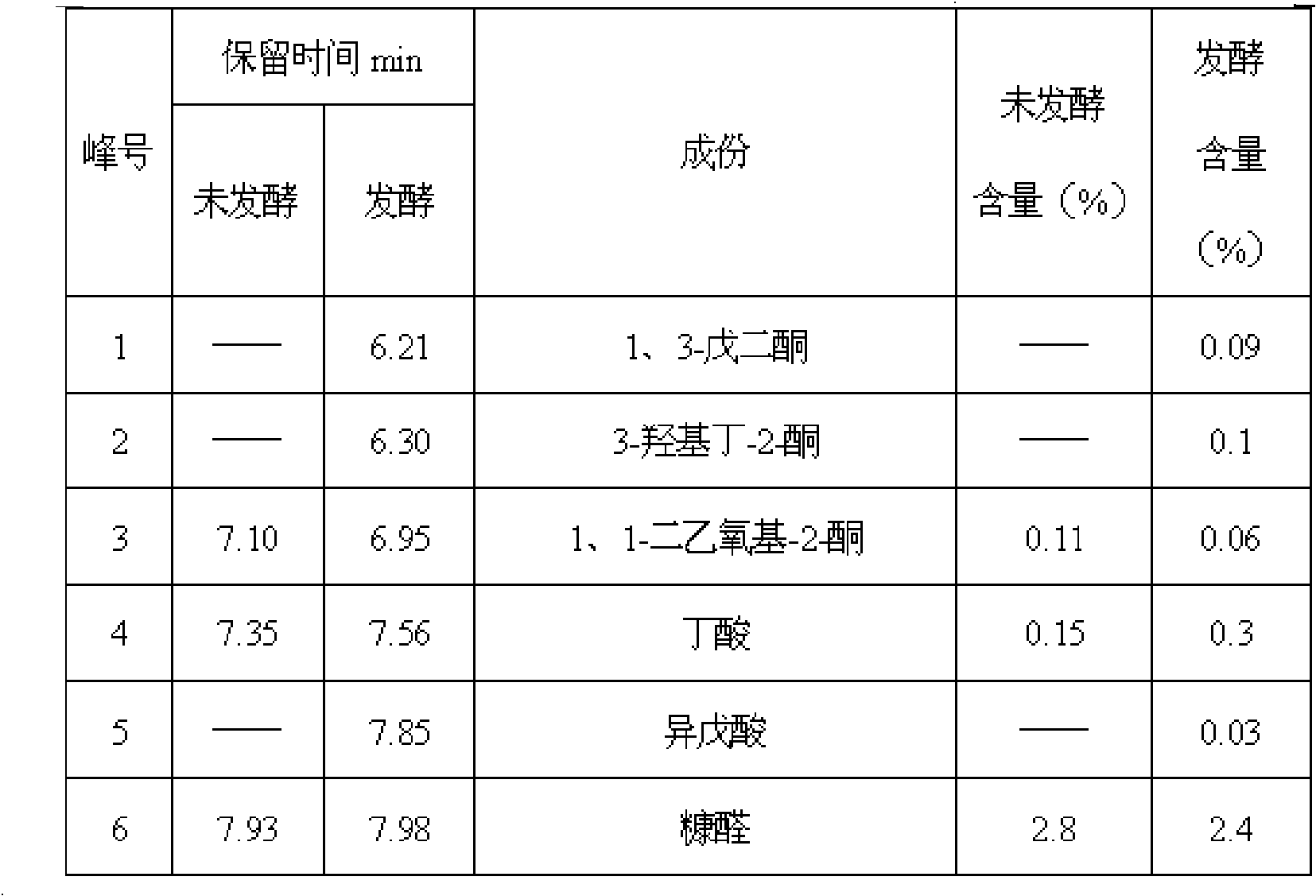

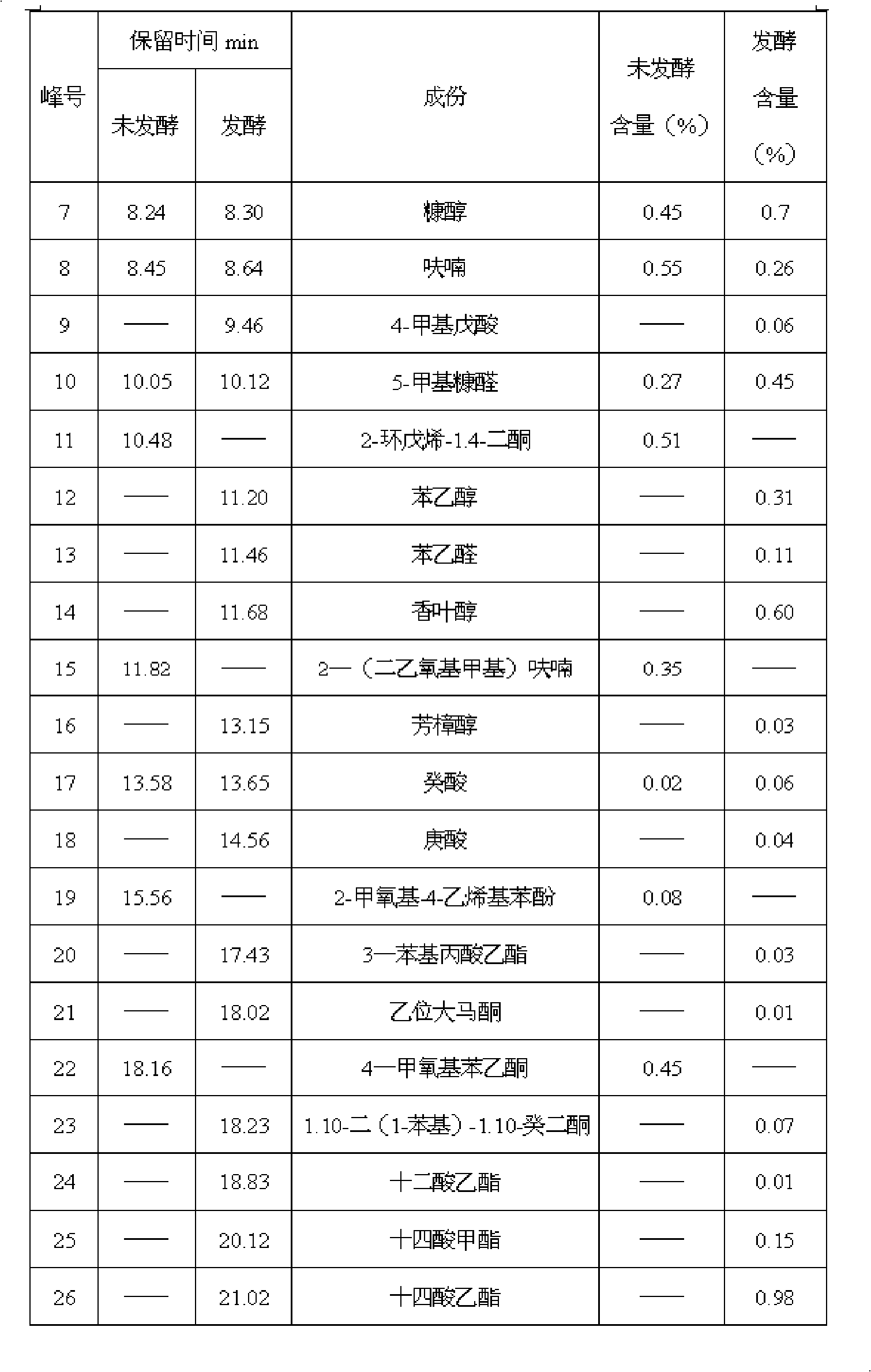

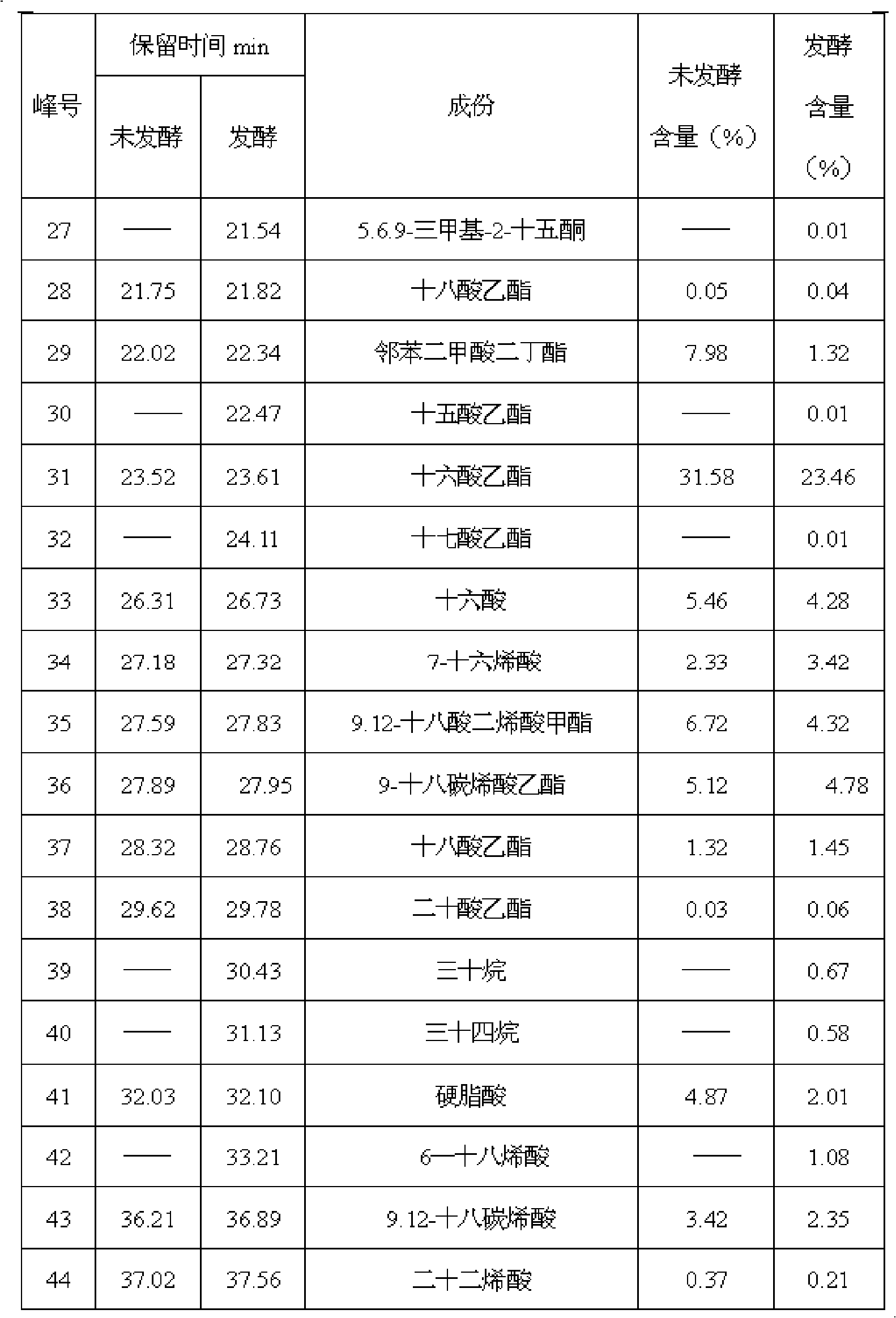

[0042] Embodiment 3: the preparation of concentrated fig juice after microbial fermentation:

[0043] Get 3 liters of activated seed liquid and inoculate in the fermenter (500 liters) that the fig concentrated juice that 180Kg the first step obtains is housed by the volume ratio of 1: 60, stir evenly and ventilate aseptic air, stirring speed 160r / min, control Air volume 1: 0.2 (V air / V liquid / per minute), control the temperature at 32-37°C for fermentation and cultivation for 48 hours, then sterilize the concentrated fig juice fermented by microorganisms at 100°C for 15 minutes, and then The concentrated fig juice after microbial fermentation is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com