Plastic hollow container extrusion blowing machine

A technology for empty containers and plastics, which is applied in the field of extrusion blow molding machines for plastic hollow containers. It can solve the problems of insufficient expansion, constant fixation, and low molding efficiency. It can reduce the intermediate link transmission mechanism, facilitate the installation of molds, and improve molding efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

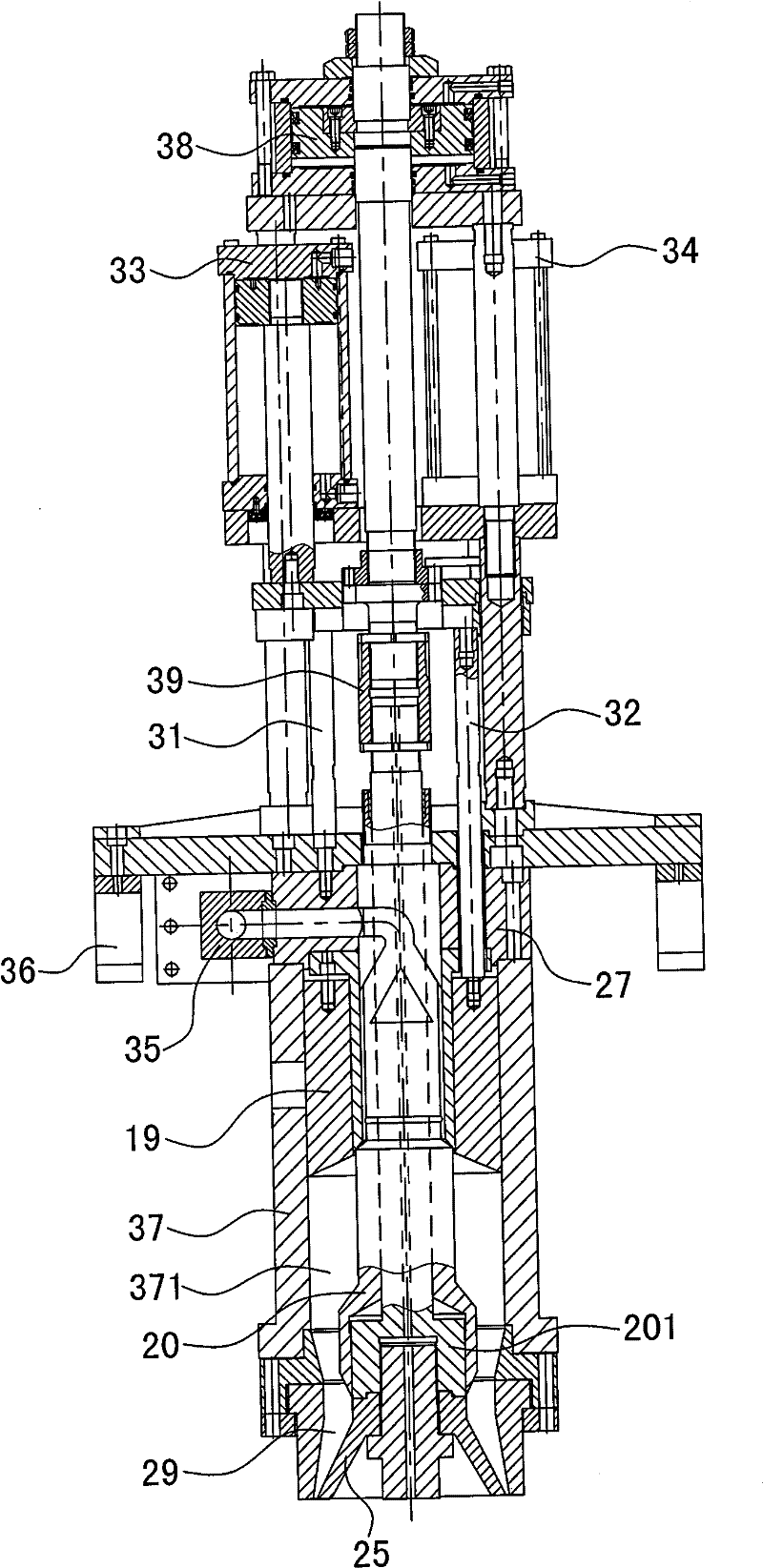

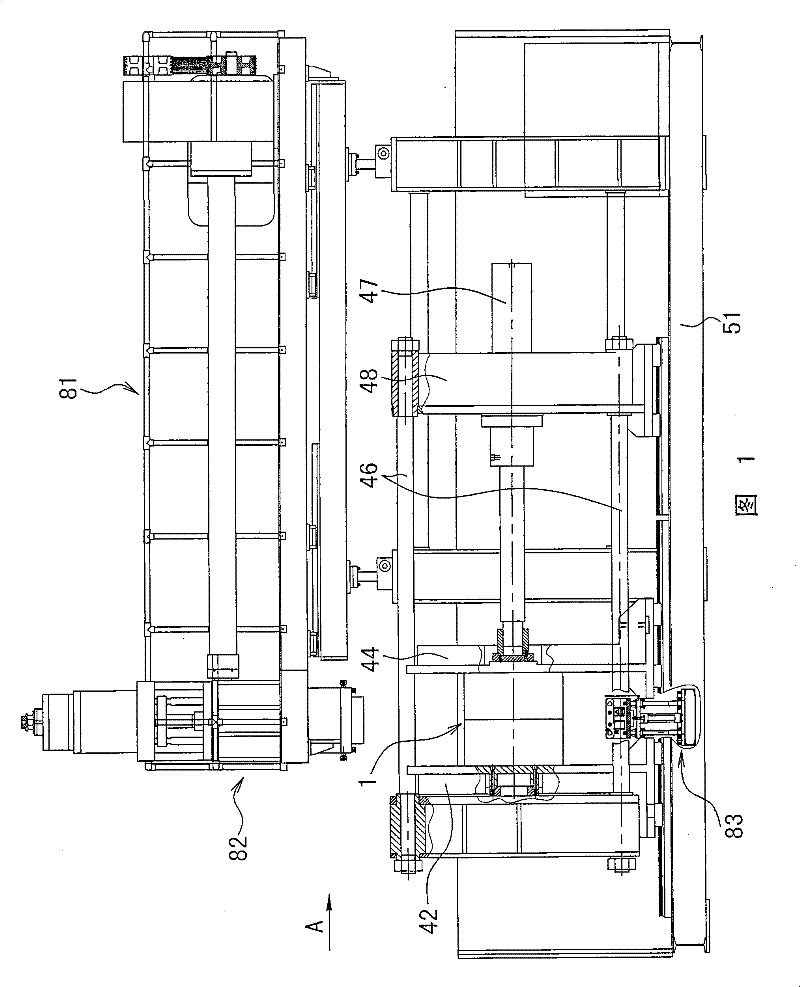

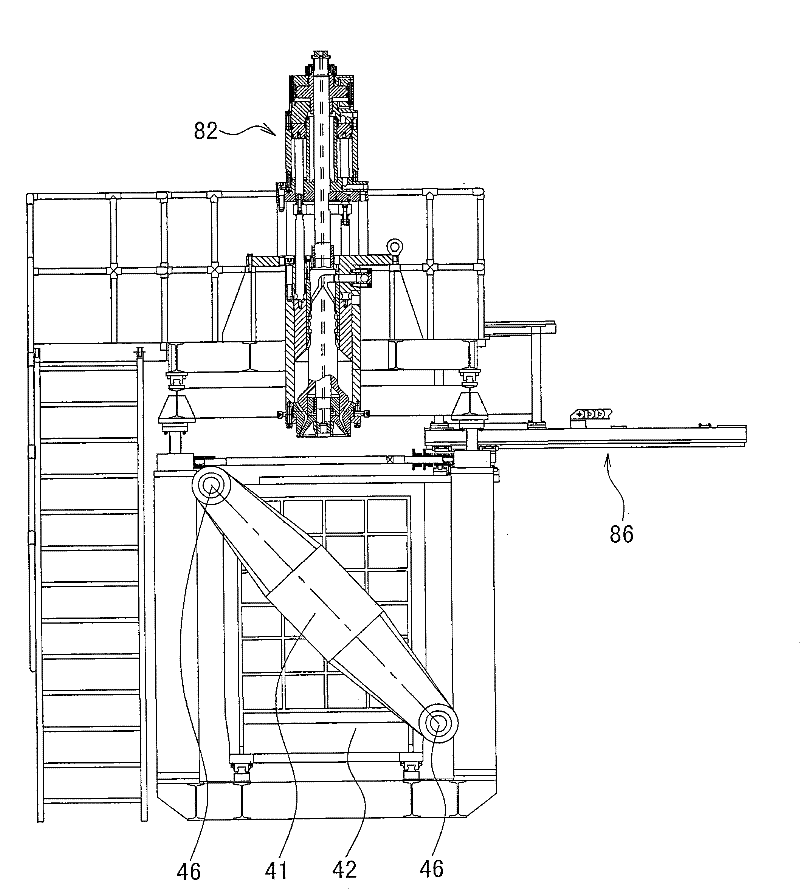

[0019] The invention discloses a plastic hollow container extrusion blowing machine, such as figure 1 , figure 2 As shown, it includes a plasticizing system 81 installed on the frame 51, a die extrusion system 82 and a blow molding system, and the plasticizing system includes a hopper, a barrel, a screw and an electric heating device; as Figure 6 As shown, the die head extrusion system 82 includes a die head support 36 installed on the frame 51, the die head support fixes the die head, and the die head includes a die head upper cover 27 and a die head body 37, inside the die head body A material storage cavity 371 is formed, and the upper cover of the die head is connected to the material cylinder and the material storage cavity through the joint neck 35. The material storage cavity 371 is equipped with an injection ring 19, and the injection ring is connected to the injection cylinder 33, 32 through the injection pillars 31 and 32. 34 piston rod; the lower end of the die h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com