Lithium-ion power battery

A power battery, lithium ion technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of poor shock resistance and extrusion resistance, shortened cycle life, shortened cycle life, etc. The effect of strong extrusion ability, good shock resistance and extrusion resistance, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

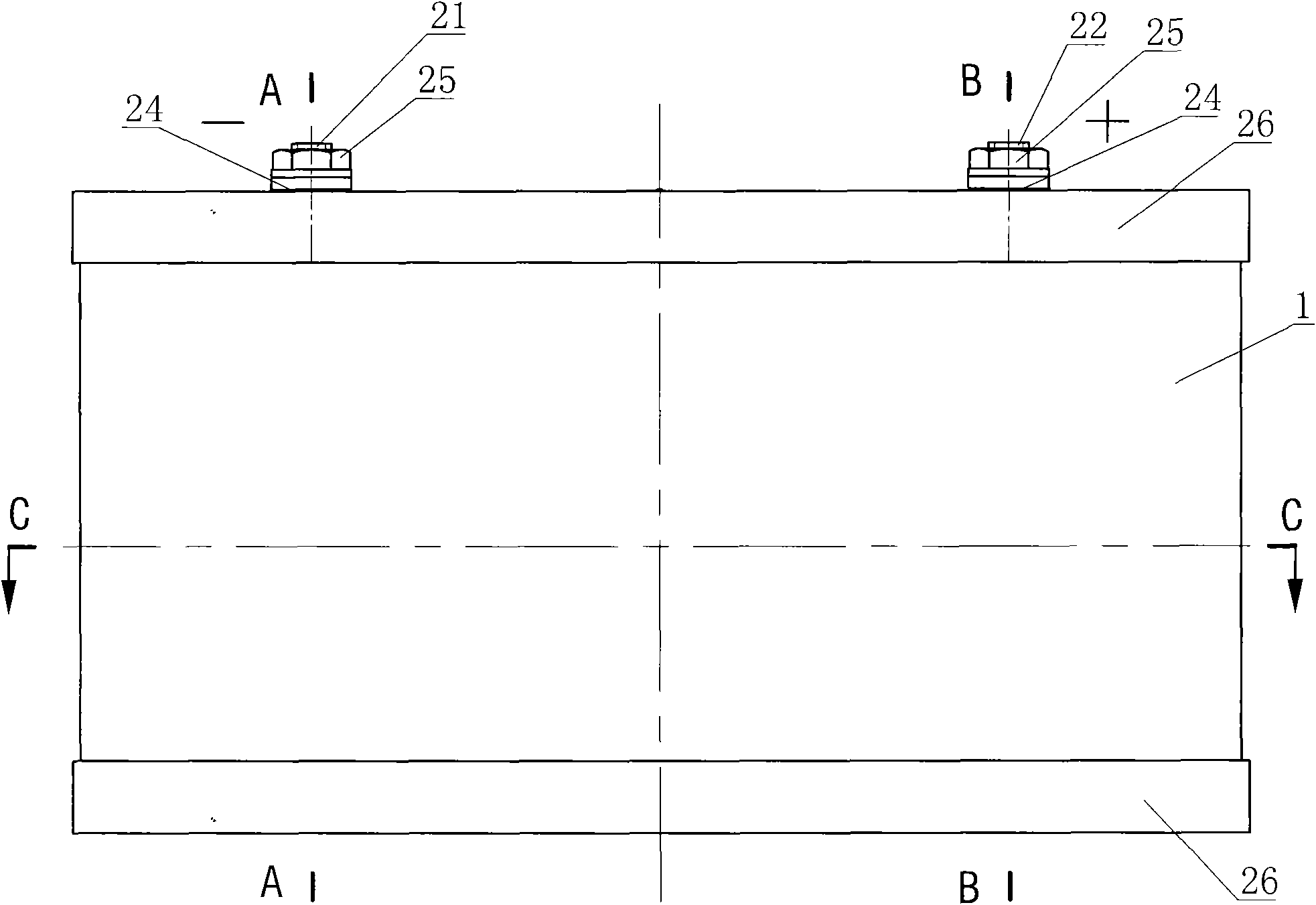

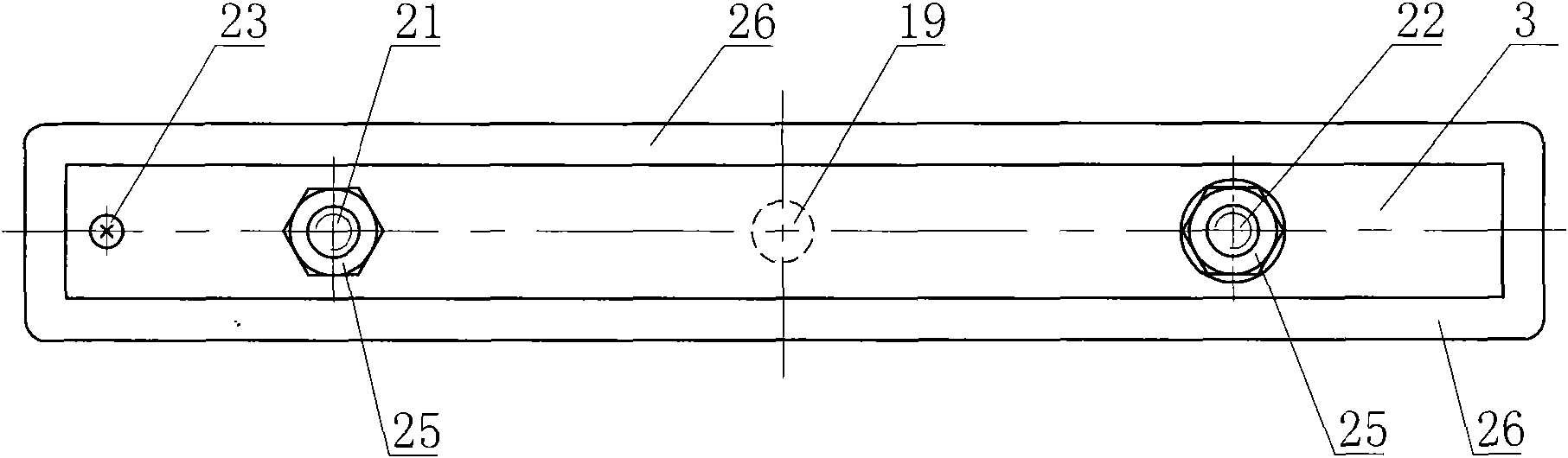

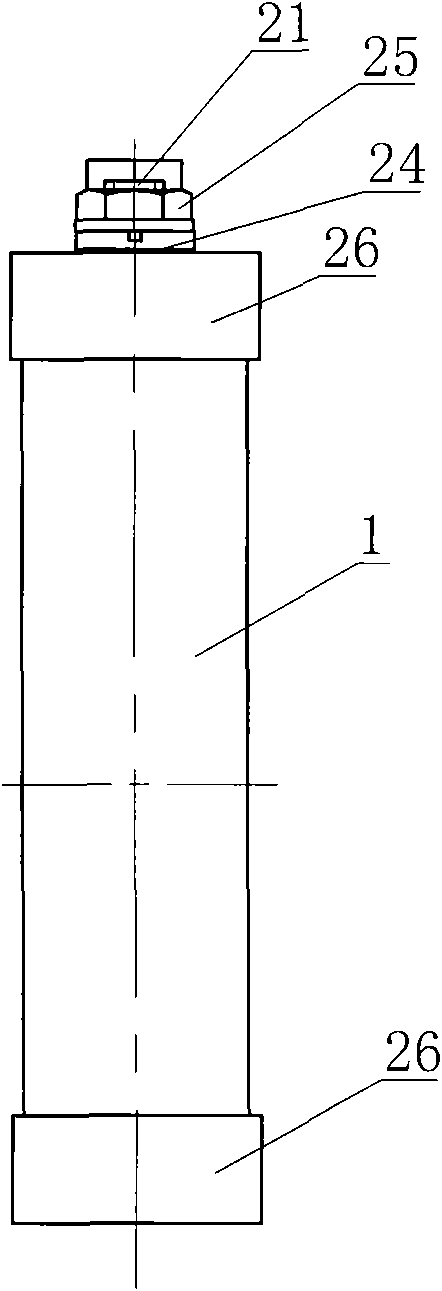

[0038] Such as Figure 1 to Figure 22As shown, a lithium-ion power battery includes a casing 1, an electronic mounting board 4 and a laminated cell 16, and also includes a negative tab joint 21 made of copper and a positive tab joint 22 made of aluminum, and also includes There is a positioning column 11 insulated from the negative electrode sheet 9, the positive electrode sheet 10, and the insulating diaphragm 7 of the laminated battery cell 16. The positioning column 11 is made of a core-piercing rivet, and the outer diameter of the middle of the core-piercing rivet is large and the outer diameter of the two ends is small. There are three positioning columns 11, including three insulating sleeves 12. The positioning column 11 is made of stainless steel, and also includes two side splints 5. Both the shell 1 and the side splints 5 are made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com