Rotary type engine

A rotary engine and rotor technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of large ineffective energy consumption, high mechanical wear, and pollution of exhaust emissions, and achieve easy manufacturing and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

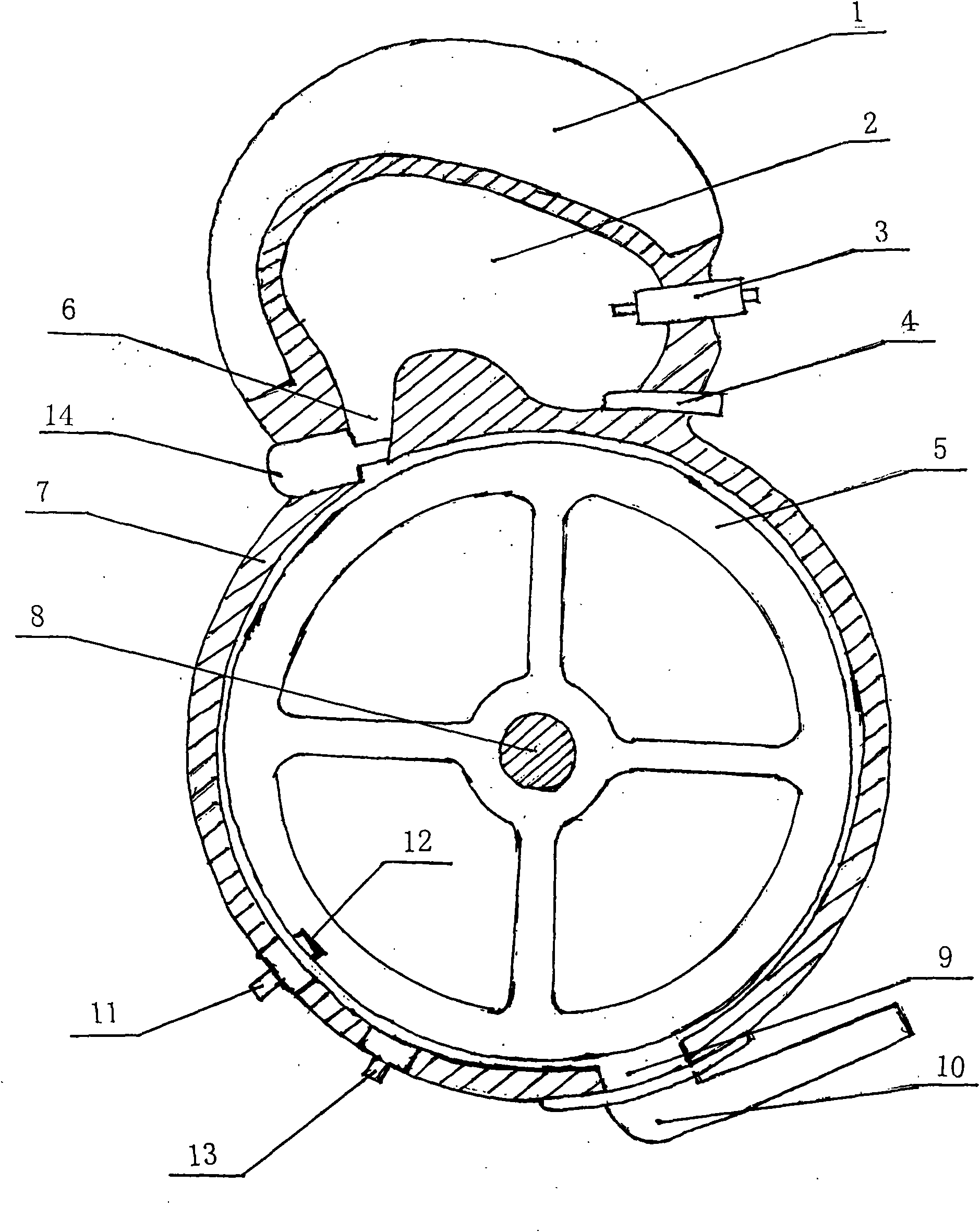

[0034] Specific embodiments are given below in conjunction with the accompanying drawings to further illustrate how the rotary engine of the present invention is realized.

[0035] Such as figure 1 As shown, the rotary engine of the present invention includes a casing 7, a rotor 5 is arranged in the casing 7, a rotor shaft 8 is fixedly arranged on the shaft center of the rotor 5, and a rotor shaft 8 of the rotor shaft 8 is fixed. Both ends stretch out the two ends of housing 7 for output power, integrally form active explosion chamber 2 on the side wall of housing 7, described power explosion chamber 2 and housing 7 are formed between the two The impact nozzle 6 communicates with each other, and the side wall of the power explosion chamber 2 is respectively provided with an air intake nozzle 4 and a high-energy igniter 3, and the impact nozzle 6 is provided with a solenoid valve 14 connected with the control unit for controlling the opening and closing of the port, On the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com